Boiler burning pulverized coal heating equipment

A technology for heating equipment and pulverized coal, used in lighting and heating equipment, combustion equipment, block/powder fuel preparation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

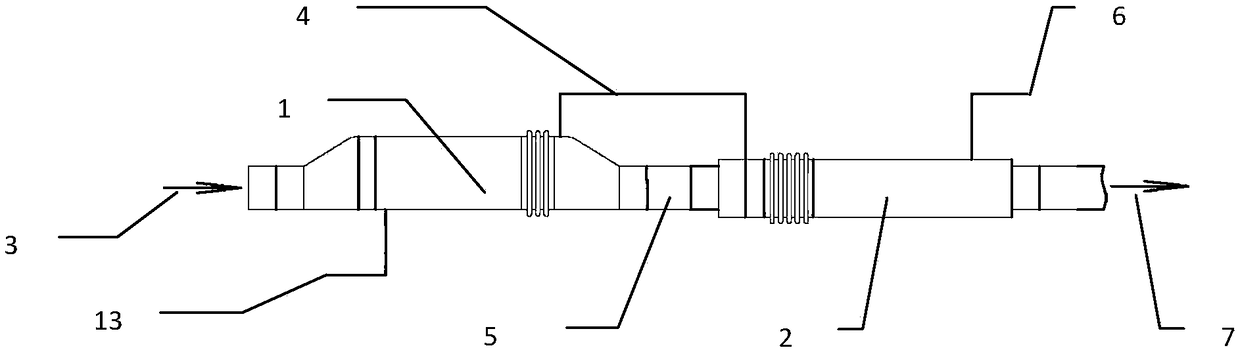

[0047] Such as figure 1 , Figure 4-1 to Figure 5-2 As shown, the boiler of the present invention uses pulverized coal heating equipment, which includes A-type pulverized coal heating equipment 1 and B-type pulverized coal heating equipment 2; A-type pulverized coal heating equipment 1 and B-type pulverized coal heating equipment 2 are arranged in series on the raw coal The other end of the A-type pulverized coal heating equipment 1 is connected to the coal mill 3; the other end of the B-type pulverized coal heating equipment 2 is connected to the boiler furnace burner 7; and A transitional steam pipeline 4 and a transitional pulverized coal pipeline 5 are provided between the A-type pulverized coal heating equipment 1 and the B-type pulverized coal heating equipment 2; a drain outlet 13 is provided on the A-type pulverized coal heating equipment 1; The heating equipment 2 is provided with a steam turbine extraction pipeline 6; wherein:

[0048] The A-type pulverized coal he...

Embodiment 2

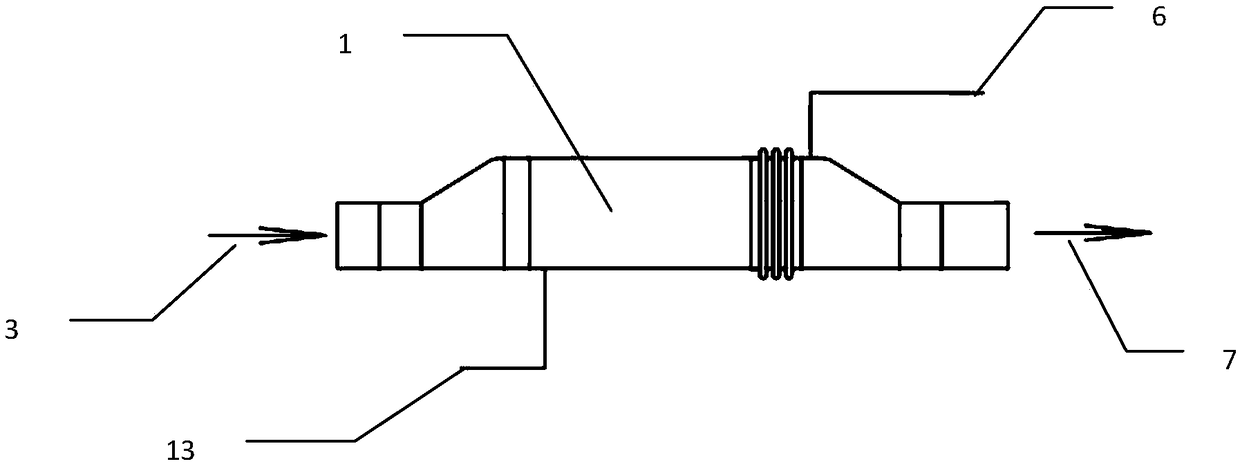

[0063] Such as figure 2 , Pic 4-1 , Figure 4-2 Shown, the boiler of the present invention burns pulverized coal heating equipment, and it comprises: A type pulverized coal heating equipment 1 is arranged on the raw pulverized coal pipeline, is connected as one with the raw pulverized coal pipeline; The coal machine 3 is connected, and its other end is connected with the boiler furnace burner 7; and a drain outlet 13 is provided on the A-type pulverized coal heating equipment 1; a steam turbine extraction pipeline 6 is also provided on the A-type pulverized coal heating equipment 1.

[0064] Wherein, the structure of the A-type pulverized coal heating equipment 1 is the same as that of the A-type pulverized coal heating equipment 1 in Embodiment 1, so it will not be repeated here.

Embodiment 3

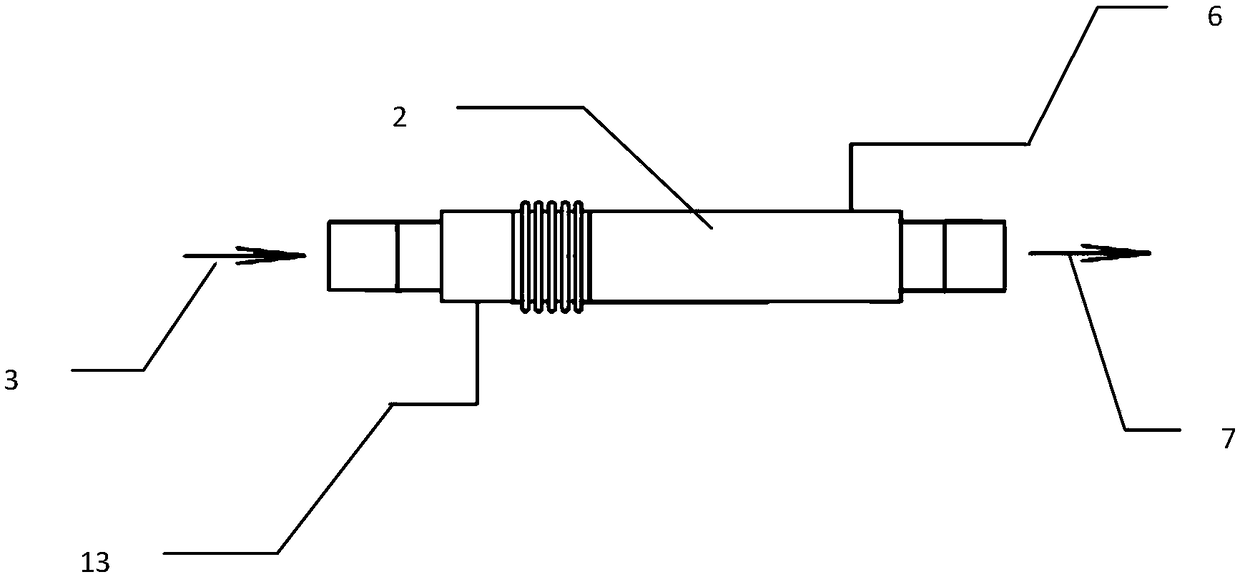

[0066] Such as image 3 , Figure 5-1 , Figure 5-2 Shown, the boiler of the present invention burns pulverized coal heating equipment, and it comprises: B type pulverized coal heating equipment 2 is arranged on the raw pulverized coal pipeline, is connected as one with the raw pulverized coal pipeline; The coal machine 3 is connected, and its other end is connected with the boiler furnace burner 7; and the B-type pulverized coal heating equipment 2 is provided with a drainage outlet 13;

[0067] Wherein, the structure of the B-type pulverized coal heating equipment 2 is the same as that of the B-type pulverized coal heating equipment 2 in Embodiment 1, so it will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com