Flow battery energy storage system

A technology of flow battery and energy storage system, applied in fuel cells, fuel cell additives, regenerative fuel cells, etc., can solve the loss of positive reactant, the imbalance of positive and negative ion concentrations, and the degree of hydrogen evolution in all-vanadium flow batteries. Small and other problems to achieve the effect of ensuring safe and stable operation and stable capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

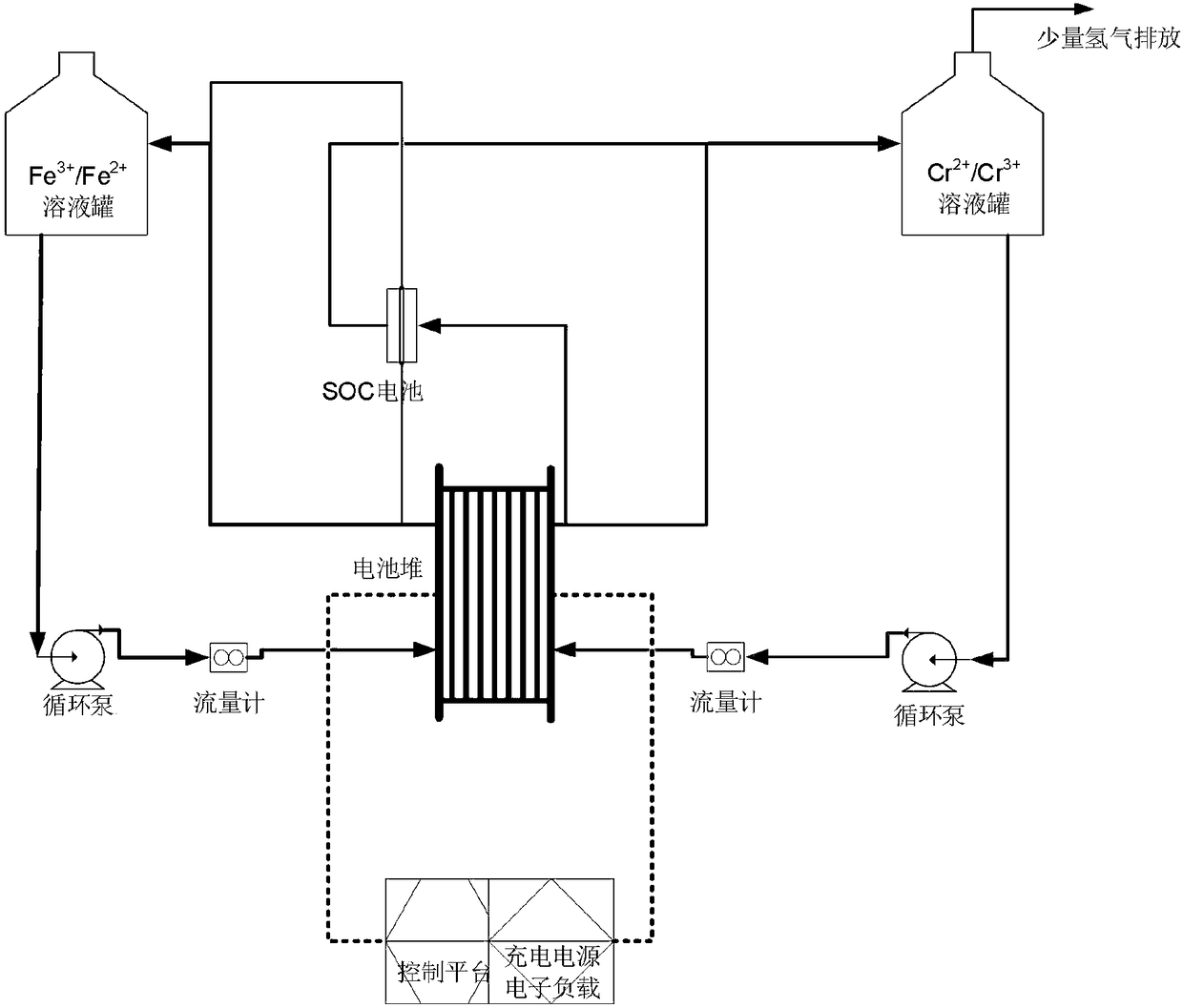

Method used

Image

Examples

Embodiment 1

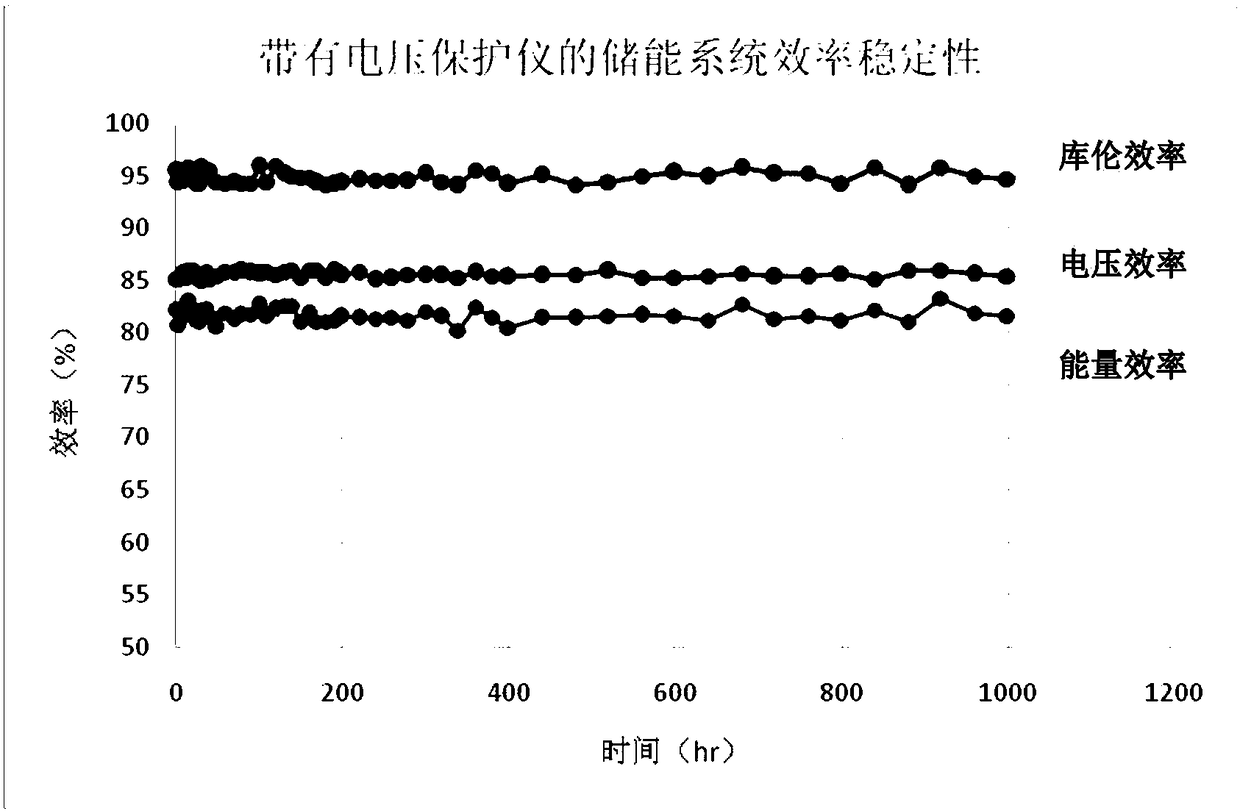

[0041] The all-vanadium redox flow battery energy storage system has a 20kW all-vanadium redox flow battery stack. The all-vanadium redox flow battery stack is composed of two 10kW sub-stacks connected in series on the circuit and fluid pipelines in parallel. Each sub-stack contains 30 For the battery unit, the number of voltage channels of the voltage protection switch should be at least 60, and the voltage with the largest voltage in the charging state, that is, the voltage with the most serious polarization, should be selected by comparison, and the maximum voltage should not be higher than the charging voltage during charging. Set value, usually 1.5V; similarly, when discharging, compare and screen out the voltage with the smallest voltage, that is, the voltage with the most serious polarization, and control the minimum voltage during discharge not to be lower than the safe setting value of discharge voltage, usually 0.85 V. After 1,000 hours of testing and about 500 charg...

Embodiment 2

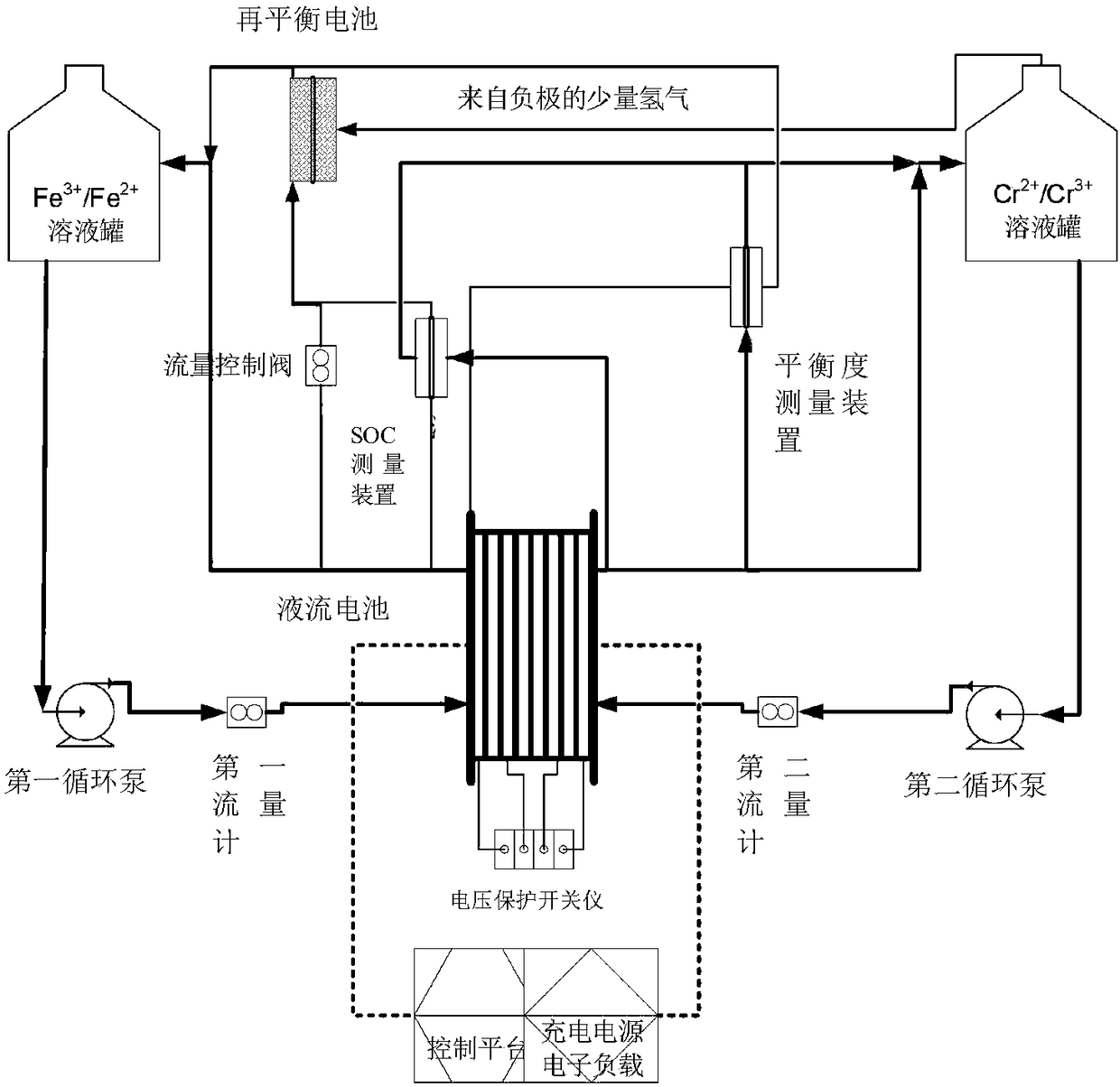

[0043] For a 2kW iron-chromium flow battery energy storage system, a rebalanced battery of about 200W is prepared, and the electrode reaction of the rebalanced battery is as follows

[0044] The positive reaction is

[0045]

[0046] The negative reaction is

[0047]

[0048] Utilizing the above rebalancing battery reaction, when the balance degree of the electrolyte solution of the energy storage system deviates from the preset balance threshold, it is usually set at 3-10%, that is, the rebalancing battery is started to reduce Fe 3+ The operation, the maximum power does not exceed 200W, and the consumed substance is only the hydrogen gas precipitated from the negative electrode, and the hydrogen gas is restored to the system, and there is no need to stop the charging and discharging operation of the main battery. It can completely make up for the Fe caused by the negative hydrogen evolution of the flow battery (the energy loss of a single charge and discharge cycle is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com