Li/Na-O2 secondary battery with Li/Na composite metal negative pole

A composite metal, secondary battery technology, applied in the direction of fuel cell type half cells and secondary battery type half cells, battery electrodes, circuits, etc., can solve the problems of limiting the actual energy density, low discharge potential, etc. Effects of battery performance, long cycle life, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

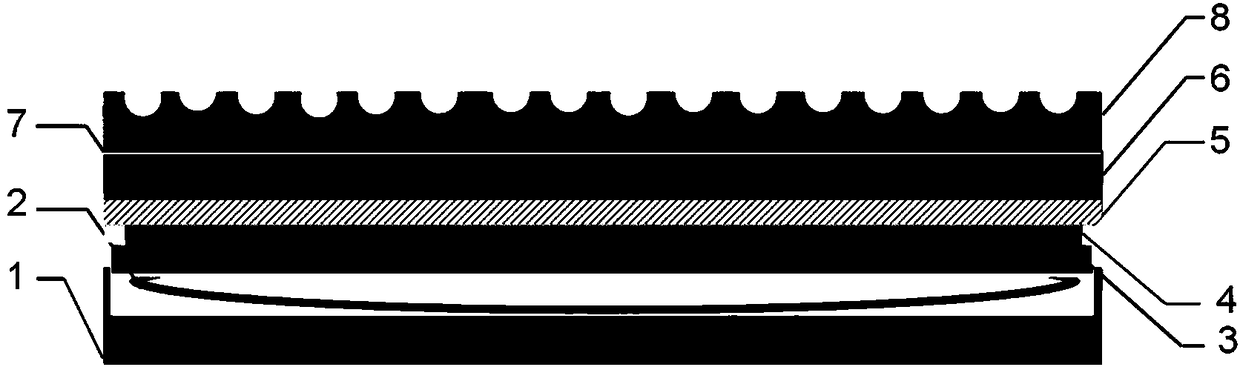

[0037] A Li / Na-O with Li / Na composite mass ratio of 2:1 2 secondary batteries, such as figure 1 As shown, it consists of negative electrode shell 1, shrapnel 2, gasket 3, Li / Na composite sheet 4, diaphragm 5, positive electrode catalyst 6, current collector 7, and porous positive electrode casing 8, wherein Li / Na composite sheet 4 is the negative electrode, and the air The (oxygen) electrode is composed of a positive electrode catalyst 6 and a current collector 7 with a porous structure; the shrapnel 2 is a stainless steel sheet, which is used to fill the internal space of the battery to improve the airtightness of the battery; the gasket 3 is a stainless steel sheet; the diaphragm 5 is located on the negative electrode Li / Na Between the composite sheet 4 and the positive electrode catalyst 6, it is used to transmit ions while blocking electrons; the electrolyte is LiClO 4 / NaClO 4 / Tetraethylene glycol dimethyl ether (TEGDME) solution, in which LiClO 4 with NaClO 4 The m...

Embodiment 2

[0045] A kind of Li / Na-O 2 The preparation method of the secondary battery is basically the same as in Example 1, except that the Li / Na mass ratio in the Li / Na composite negative electrode used is 1:2.

[0046] Figure 9 It is an optical photo of a Li / Na composite negative electrode with a Li / Na mass ratio of 1:2, showing that the thickness of metal sodium and metal lithium is uniform, and the cross-section is neat. Figure 10 The middle curve ② is the Li / Na composite negative electrode with Li / Na mass ratio of 1:2-O 2 Secondary battery 200mA g -1 Charge and discharge performance graph, at 200mAg -1 Charge and discharge at current density, compared with pure Na anode, the discharge platform is increased by 0.2V. Figure 11 The middle curve ② is the Li / Na composite negative electrode with Li / Na mass ratio of 1:2-O 2 Secondary battery 100mAg -1 Charge and discharge performance graph, at 100mAg -1 Charge and discharge at current density, compared with pure Na anode, the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com