Smoke filter material and preparation method and application thereof

A technology for filtering materials and flue gas, applied in the field of materials, can solve problems such as the difficulty of harmful gases, and achieve the effect of improving the overall filtering performance, increasing the moisture, and enhancing the adsorption function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

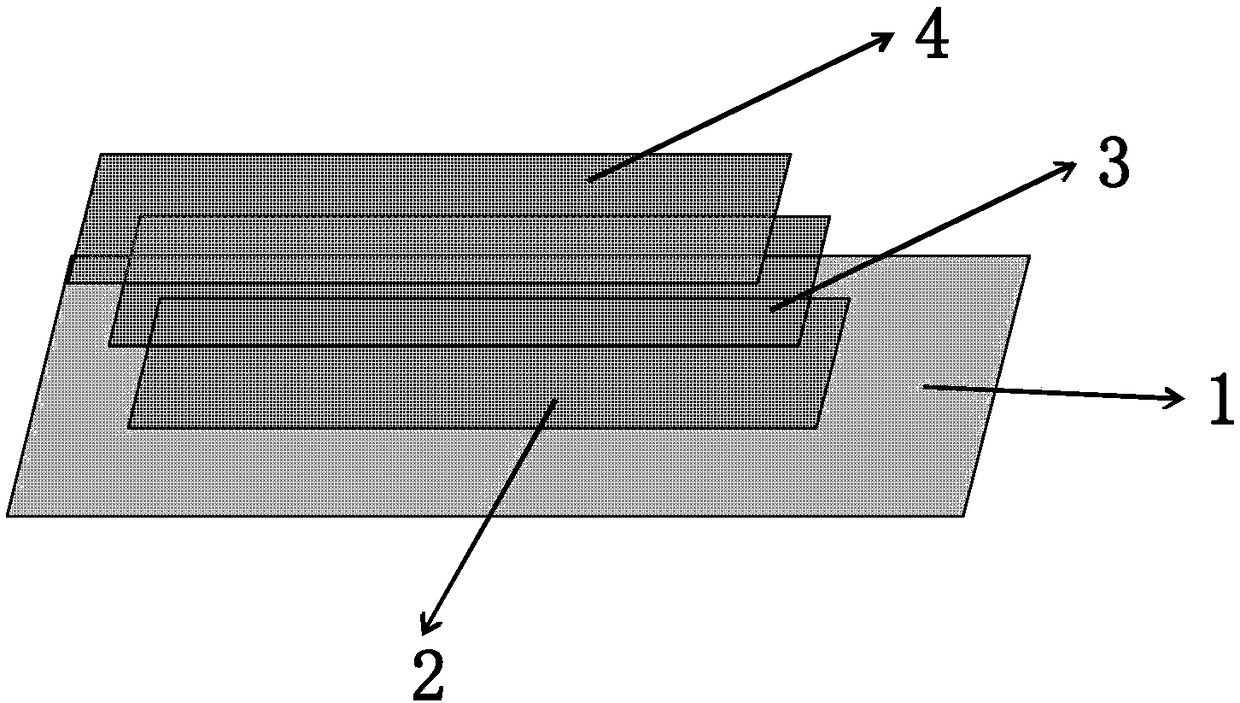

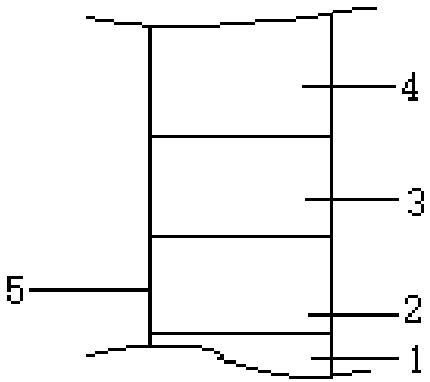

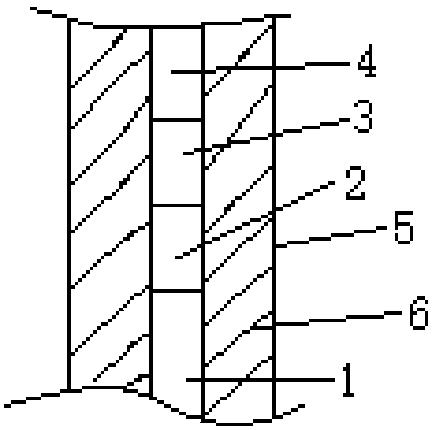

[0041] A smoke filter material includes a non-woven fabric layer 1, a cellulose diacetate film layer 2 with a thickness of 15 μm, a PVDF fiber film layer 3 with a thickness of 3 μm, a cellulose diacetate film layer 4 with a thickness of 20 μm, and a smoke filter material The diameter of the fiber is 200nm; the ratio of the total solid content of the cellulose diacetate layer to the solid content of the lipophilic polymer film layer is 18:1.

Embodiment 2

[0043] A smoke filter material includes a non-woven fabric layer 1, a cellulose diacetate film layer 2 with a thickness of 20 μm, a PAN fiber film layer 3 with a thickness of 4 μm, a cellulose diacetate film layer 4 with a thickness of 10 μm, and a smoke filter material The diameter of the fiber is 230nm; the ratio of the total solid content of the cellulose diacetate layer to the solid content of the lipophilic polymer film layer is 12:1.

Embodiment 3

[0045] A smoke filter material includes a non-woven fabric layer 1, a cellulose diacetate film layer 2 with a thickness of 10 μm, a PVDF fiber film layer 3 with a thickness of 5 μm, a cellulose diacetate film layer 4 with a thickness of 12 μm, and a smoke filter material The diameter of the fiber is 450nm; the ratio of the total solid content of the cellulose diacetate layer to the solid content of the lipophilic polymer film layer is 15:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com