A process for eliminating static electricity of polyvinyl chloride powder

A technology for polyvinyl chloride powder and polyvinyl chloride powder, which is applied in the field of electrostatic elimination of polyvinyl chloride powder, can solve the problems of full bag dust, environmental impact, scattering, etc., and achieves small change range, environmental improvement, and reduction of transformation. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

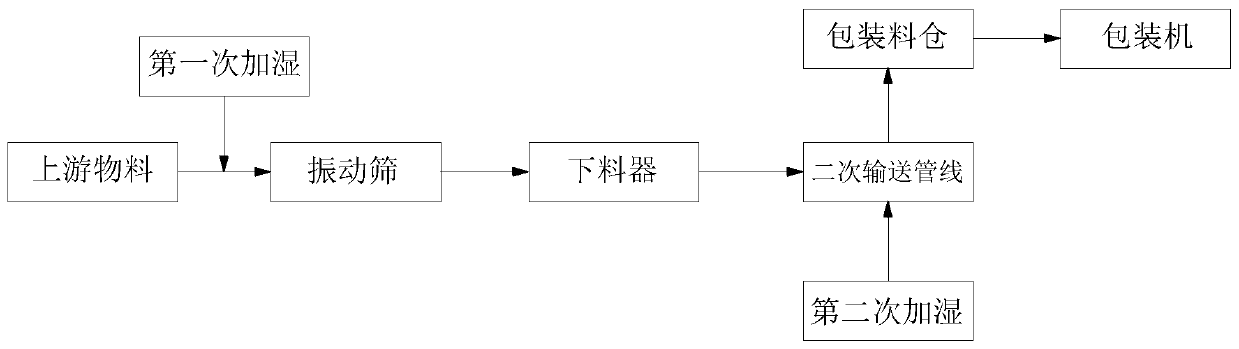

[0034] A process for eliminating static electricity of polyvinyl chloride powder, such as figure 1 As shown, the system used includes a vibrating screen, a feeder, a secondary conveying pipeline, and a packaging silo connected in sequence. The inlet pipeline of the vibrating screen is provided with a first humidification device, and the secondary conveying pipeline is provided with an atomization device. The inlet of the first humidifying device is connected to the first steam pipeline, the inlet of the atomizing device is connected to the second steam pipeline, and the spraying direction of the atomizing device is perpendicular to the flow direction of polyvinyl chloride.

[0035] The air-dried polyvinyl chloride powder from the upstream is humidified for the first time in the inlet pipe of the vibrating screen, then vibrating and sieving, and then fed to the secondary conveying pipeline, and the polyvinyl chloride powder in the secondary conveying pipeline undergoes the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com