Immobilized microalgae reactor taking mycelium pellets as carriers and wastewater processing method

A technology of reactor and mycelium ball, which is applied in the field of immobilized microalgae reactor and wastewater treatment, can solve the problems of poor sewage treatment effect, poor microalgae settlement performance, and poor stable operation performance, so as to save cultivation cost, Saving acclimation time and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

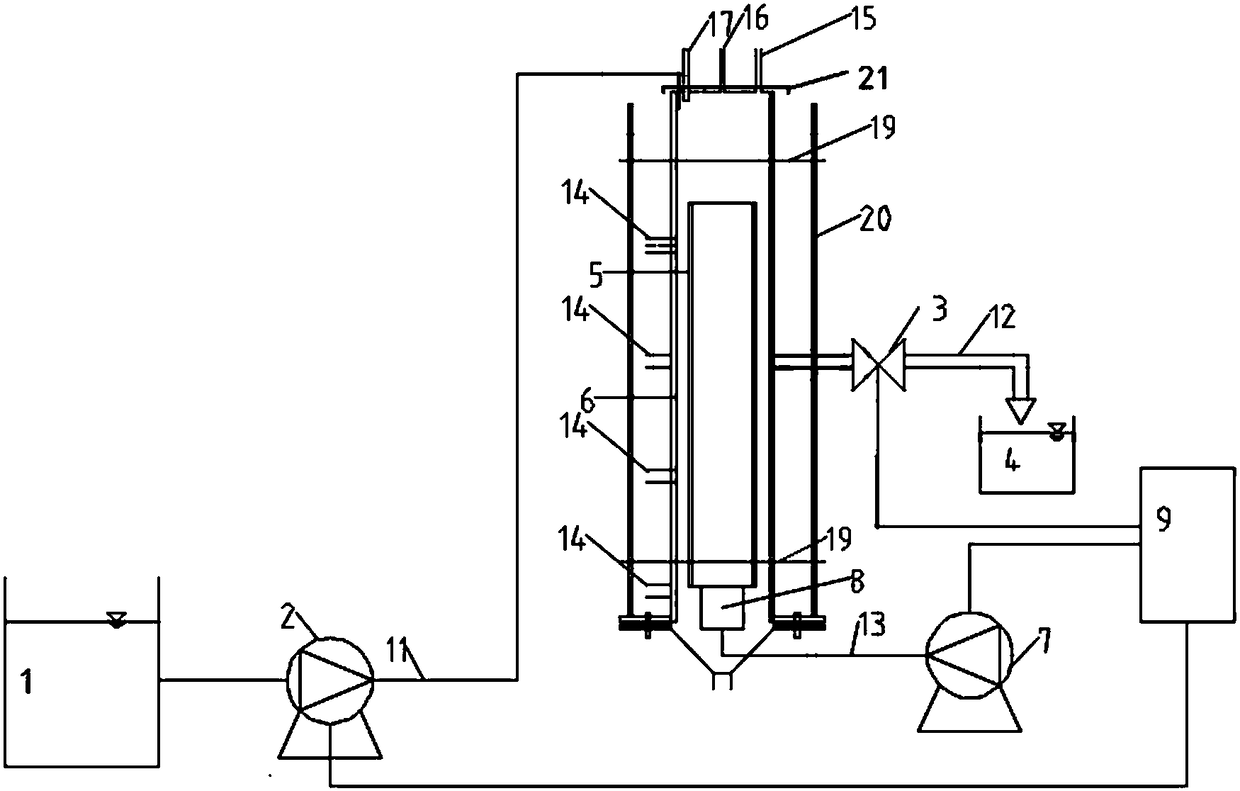

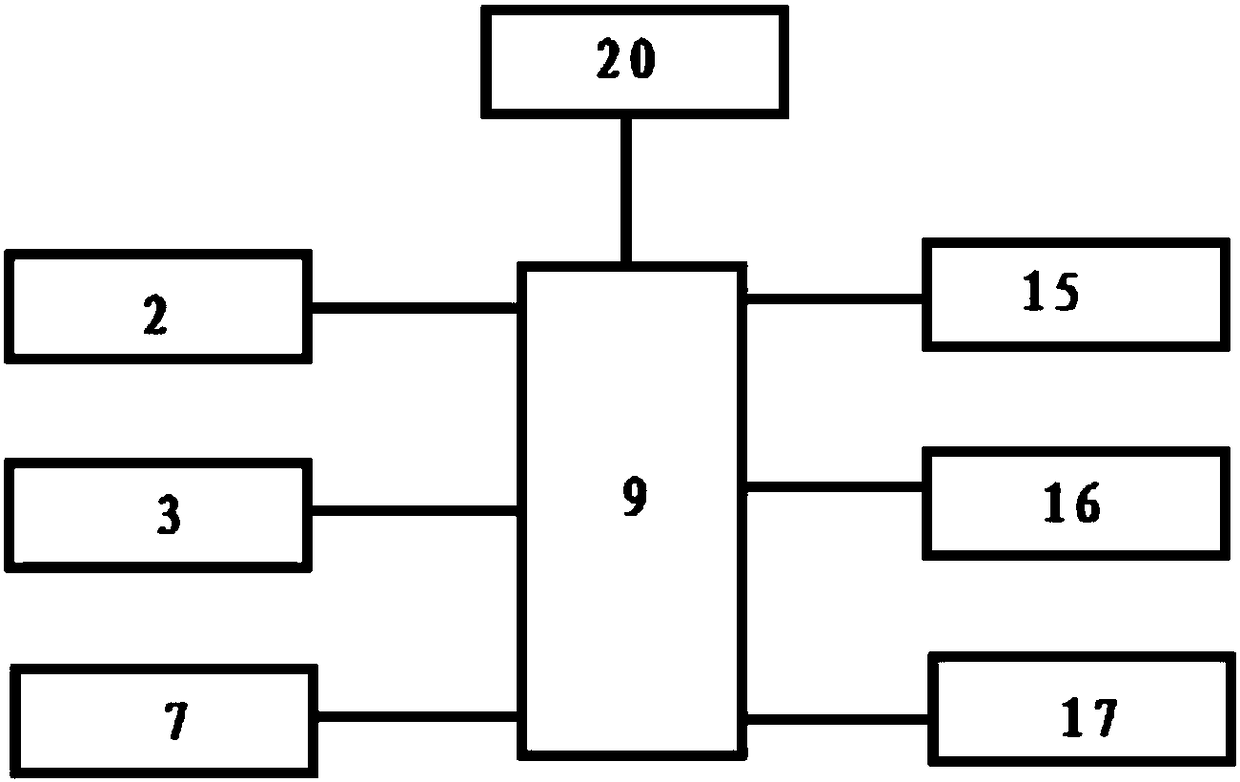

[0072] Step 1, making an immobilized microalgae reactor with mycelium balls as a carrier: the reactor includes a water inlet system, a reactor body and a water outlet system, and the water inlet system includes a water inlet tank 1, and the water inlet tank 1 passes through a pipeline The water inlet pump 2 and the water inlet pipe 11 are connected in sequence;

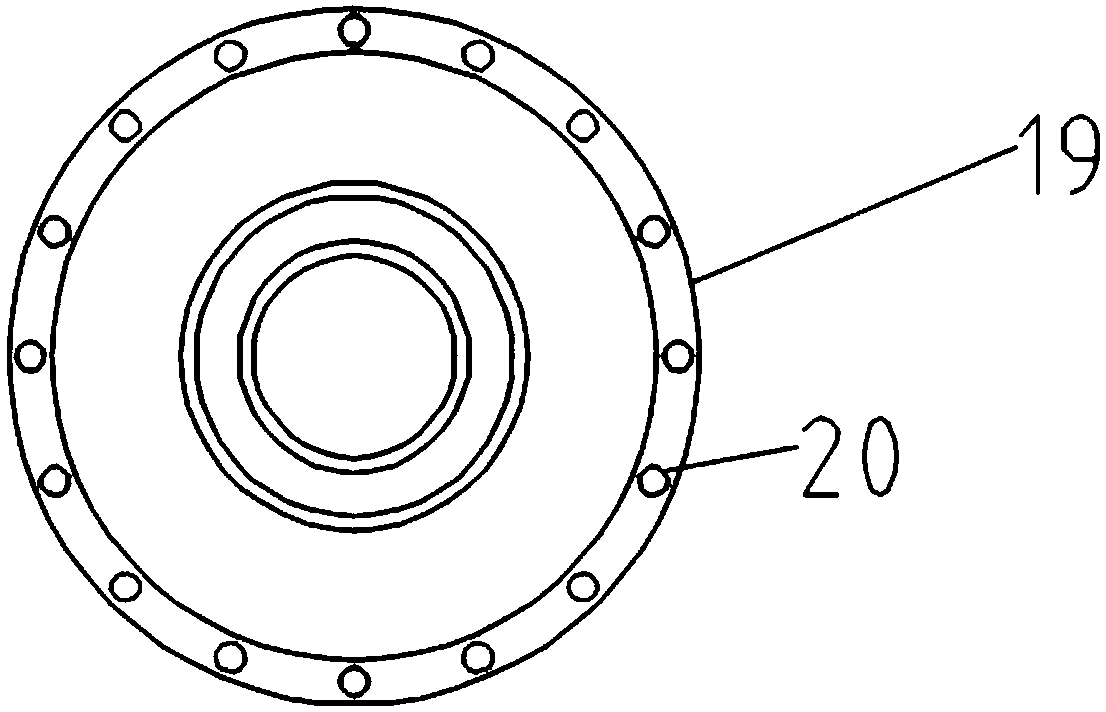

[0073] The main body of the reactor includes a riser 5 and a downcomer 6; the other end of the inlet pipe 11 communicates with the top of the downcomer 6, and the downcomer 6 is located in the lumen of the riser 5, and the riser 5 and the downcomer 6 The coaxial line is set from inside to outside; the bottom of the downcomer 6 is provided with an aeration head 8, and the aeration head 8 communicates with the air compressor 7 through the intake pipe 13;

[0074] The water outlet system includes a water outlet box 4 and an outlet pipe 12, the outlet pipe 12 is installed on the side wall of the downpipe 5;

[0075] Opti...

Embodiment 2

[0098] Step 1 and step 2 are the same as embodiment 1;

[0099] Step 3. Rapid start-up and operation of the bacteria and algae symbiosis system:

[0100] Step 3.1, water intake: same as Example 1;

[0101]Step 3.2, formation of coupled particle system: Inoculate 1:10 (reactor sewage volume) concentrated algae liquid and broken mycelium (200mg / L final inoculation concentration) at the inoculation port, and add a certain amount of biological flocculant (1:50 (reactor sewage volume)) and photosynthetic bacteria concentrate (1:50 (reactor sewage volume)), start the air compressor at this time, compressed air is supplied into the reactor main body by the aeration head through the air intake pipe, and the reactor main body Driven by the updraft, the sewage in the tank moves upwards in the riser, rises to the connection between the upper end of the riser and the downcomer, enters the downcomer, and then moves down to the bottom of the reactor; the fungal spores gradually form bacter...

Embodiment 3

[0105] Step 1 and step 2 are the same as embodiment 1;

[0106] Step 3. Rapid start-up and operation of the bacteria and algae symbiosis system:

[0107] Step 3.1, water intake: same as Example 1;

[0108] Step 3.2, formation of coupled particle system: Inoculate 1:10 (reactor sewage volume) concentrated algae liquid and mycelial balls (400mg / L final inoculation concentration) at the inoculation port, and add a certain amount of biological flocculant (1:150( Reactor sewage volume)) and photosynthetic bacteria concentrate (1:150 (reactor sewage volume)), start the air compressor at this time, compressed air is supplied into the reactor main body by the aeration head through the air intake pipe, and the reactor main body Driven by the updraft, the sewage moves upwards in the riser, rises to the connection between the upper end of the riser and the downcomer, enters the downcomer, and then moves down to the bottom of the reactor; the fungal spores gradually form hyphae after 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com