A kind of brick adobe and glazed ceramic tile production method of dry process pulverization

A technology of dry powder making and production method, which is applied in the field of ceramic tile production, can solve the problems such as uneven surface of dry powder powder brick adobe, achieve the effect of improving glaze color and pattern expressiveness, enriching expressive force, and improving the quality of ceramic tiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A kind of adobe production method of dry pulverization, comprises steps (1)~(5), specifically as follows:

[0073] (1) The powder produced by the dry method is pressed into an adobe, and the adobe is a green adobe, and the adobe strength is 3Mpa. The moisture content of the adobe is 9%. The formula of the adobe contains 30% bentonite, the maximum pressure for pressing the adobe is 320Mpa, and the strength of the adobe after pressing can reach 3Mpa. The density of the adobe is 1.810g / cm 3 .

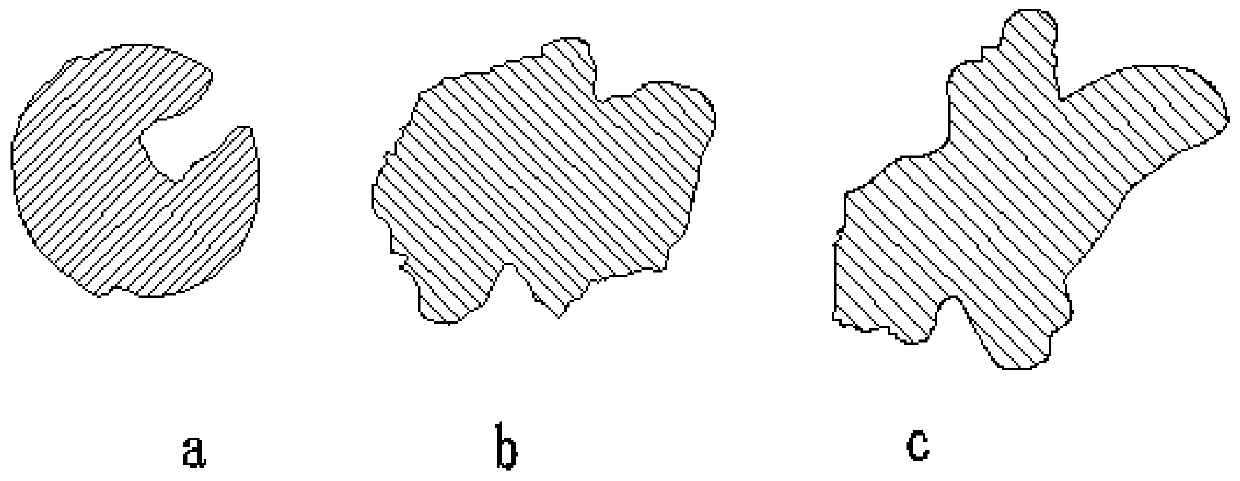

[0074] (2) The adobe is baked with a high-temperature lamp, and then the adobe is thrown and cut by an abrasive belt throwing machine with a thickness of 0.3 mm. Specifically, the adobe is transported to the bottom of the abrasive belt through the conveying mechanism, and the high-temperature lamp is set on the side of the conveying mechanism. The baking temperature of the high-temperature lamp is 105.3-110.7°C, and the baking time is 7 minutes. The edge of the adobe is closest t...

Embodiment 2

[0083] The brick adobe production method of the dry process pulverization of the present embodiment and the method for producing glazed ceramic tile are basically the same as embodiment 1, the difference is:

[0084] In step (1), the adobe strength is 4Mpa, and the moisture content of the adobe is 5%, and 45% bentonite is added in the formula of the adobe, and the maximum pressure of pressing the adobe is 300Mpa, so that the strength of the adobe reaches 4Mpa, and the compactness of the adobe 1.923g / cm 3 ;

[0085] In step (2), the throwing thickness is 0.1 mm, the baking time is 5 minutes, and the mesh numbers of the three sets of abrasive belts of the abrasive belt throwing machine are 320 mesh, 400 mesh, and 600 mesh.

Embodiment 3

[0087] The brick adobe production method of the dry process pulverization of the present embodiment and the method for producing glazed ceramic tile are basically the same as embodiment 1, the difference is:

[0088] In step (1), the strength of the adobe is 3.5Mpa, and the moisture content of the adobe is 7%. In the process of humidifying and granulating the powder for preparing the adobe, an organic particle reinforcing agent is added in an amount of 0.15%, and the amount of the adobe is pressed. The maximum pressure is 300Mpa, and the density of the adobe is 1.815g / cm 3 ;

[0089] In step (2), the throwing thickness is 0.2 mm, the baking time of the high-temperature lamp is 6 minutes, and the mesh numbers of the three groups of abrasive belts are 400 mesh, 400 mesh, and 600 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com