Organic electroluminescence material containing phenanthrene structure and organic luminescence device thereof

An organic light-emitting device and luminescent technology, applied in the direction of luminescent materials, electric solid devices, electrical components, etc., can solve the problems of low lifespan and low luminous efficiency, and achieve wide energy gap, high luminous efficiency, and carrier transport balance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

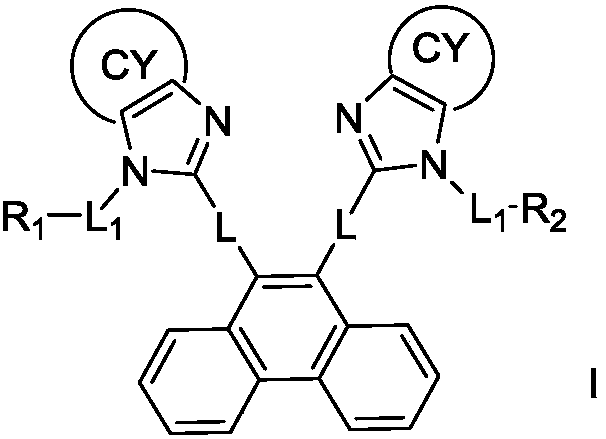

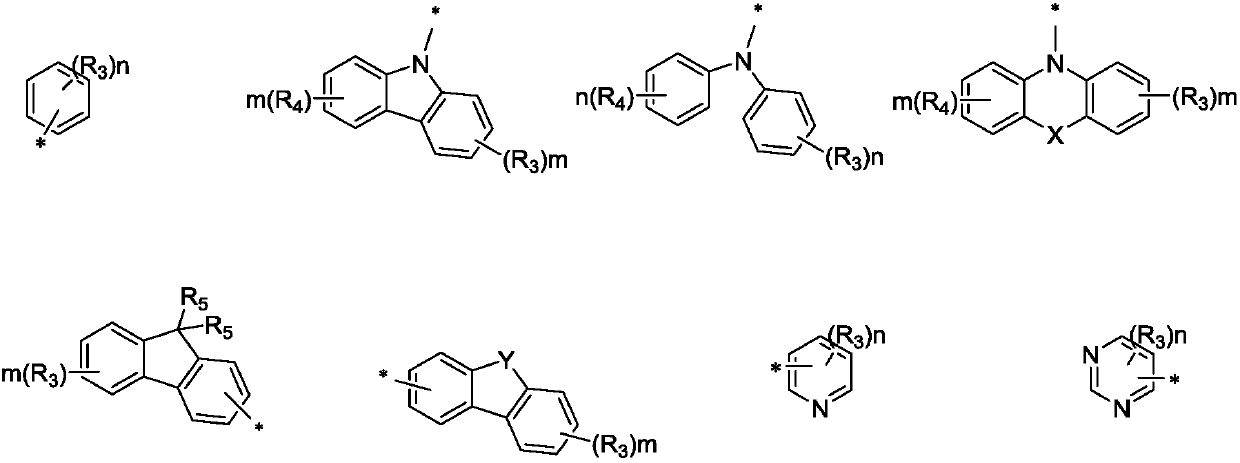

Method used

Image

Examples

Embodiment 1

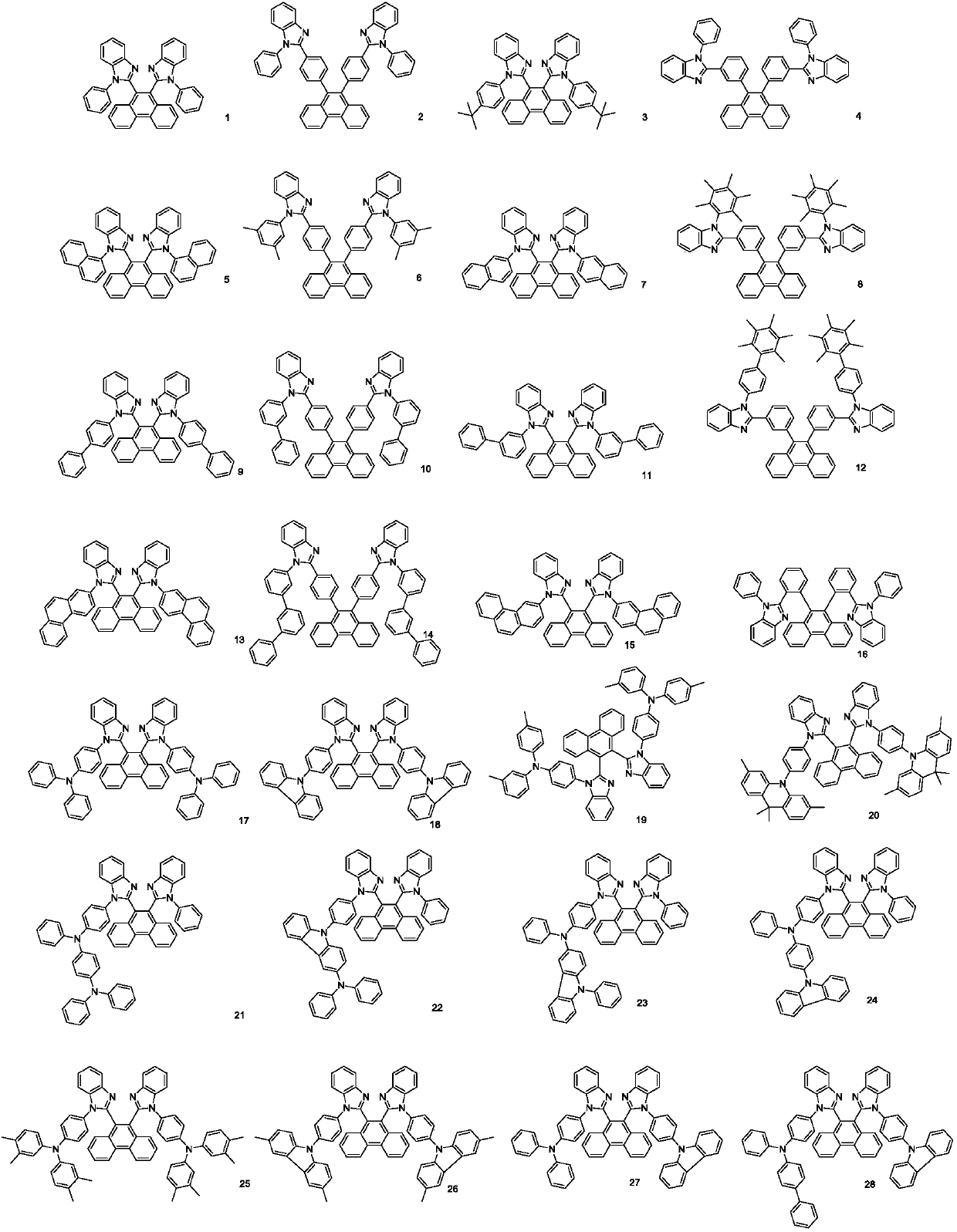

[0076] Embodiment 1: the preparation of compound 1

[0077]

[0078] Step1. Dissolve 1-3, 100mmol in anhydrous THF, cool to -78°C, add 150mmol of n-butyllithium dropwise, react at this temperature for 1 hour, add 2 equivalents of DMF, gradually raise the temperature to 0°C, and react Overnight, after the reaction was completed, 500 mmol of deionized water was added. After the reaction was completed, DCM was added for extraction, the organic phase was spin-dried, and column chromatography was performed to obtain the product 1-2, 70 mmol.

[0079] Step2. Products 1-2, 70mmol, 1-1, 140mmol, dissolved in a mixed solvent of DMF and water at a ratio of 9:1 (v / v), heated to 80 degrees Celsius, fed with oxygen, stirred and reacted for 6 hours, after the reaction was completed , the organic phase was spin-dried and subjected to column chromatography to obtain 35 mmol of the product.

Embodiment 2

[0080] Embodiment 2: the preparation of compound 2

[0081]

[0082] Step1. Under the protection of nitrogen, take 1-3, 100mmol, 100mmol of p-chlorophenylboronic acid, 300mol of potassium carbonate, 1mol of tetraphenylphosphopalladium, a mixed solvent of toluene, ethanol and water for ultrasonic deoxygenation, stir and dissolve, and replace the air three times , Reflux reaction for 6h. Cool to room temperature, add enough dichloromethane to completely dissolve the product, pass through a small amount of silica gel funnel, and remove catalyst and salt. The filtrate was concentrated to a viscous state and subjected to column chromatography to obtain product 2-3, 85 mmol.

[0083] Step2. Dissolve 2-3, 85mmol in anhydrous THF, cool to -78°C, add 100mmol of n-butyllithium dropwise, react at this temperature for 1 hour, add 2 equivalents of DMF, gradually raise the temperature to 0°C, and react Overnight, after the reaction was completed, 200 mmol of deionized water was added. ...

Embodiment 3

[0085] Embodiment 3: the preparation of compound 5

[0086] With embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com