Method for cooperated treatment of domestic garbage combustion fly ash through copper smelting and application thereof

A technology of domestic waste incineration and waste incineration fly ash, which is applied in the direction of chemical instruments and methods, process efficiency improvement, solid waste removal, etc., can solve the problems of limited utilization of resources, inability to degrade dioxin, etc., and achieve Reduce processing costs, reduce stacking, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a method for cooperating with copper smelting to process domestic waste incineration fly ash, which mainly includes the following steps:

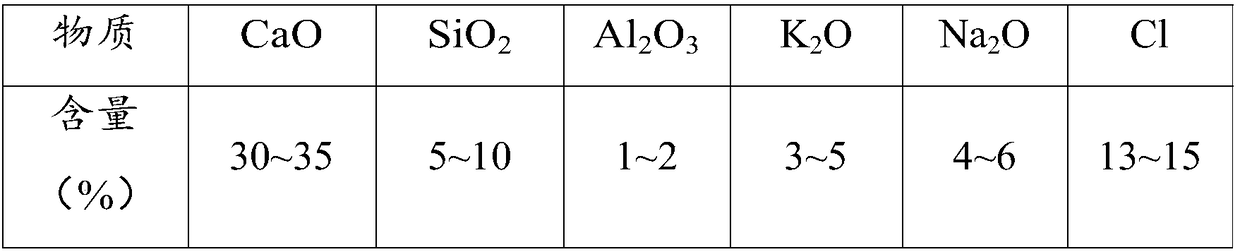

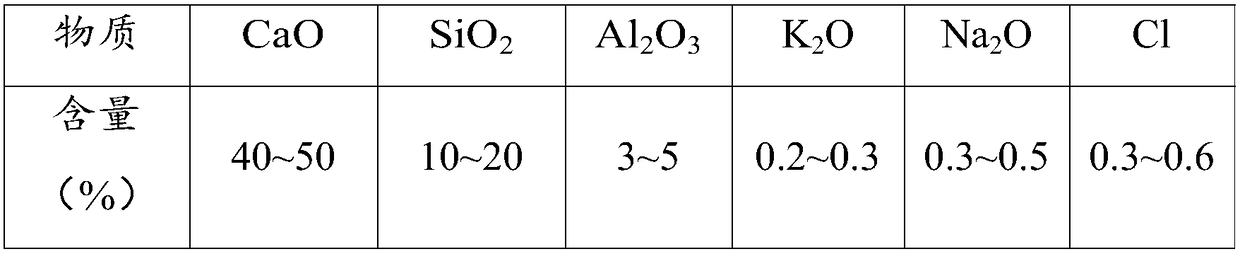

[0028] Composition of a domestic waste incineration plant: CaO 32.74%, Al 2 o 3 1.55%, SiO 2 8.79%, K 2 O4.67%, Na 2 O 4.84%, Cl 14.12%. The above garbage incineration fly ash was taken, washed with water at 20°C for 1.5 hours, and dried at 60°C for 2 hours. Composition of fly ash after water washing: CaO 45.91%, Al 2 o 3 3.26%, SiO 2 14.15%, K 2 O 0.29%, Na 2 O 0.41%, Cl 0.46%.

[0029] During the copper smelting process, the composition of the copper concentrate fed into the furnace is 25.90% Cu, 24.51% Fe, 33.27% S, 6.15% Zn, and 2.25% Pb. The amount of fly ash added to 1 ton of concentrate is 0.01 tons (the mass ratio of fly ash to copper concentrate is 1:100), and the smelting is carried out under the condition of 1200 ℃, and the dioxin is completely decomposed to produce 0.54 tons of slag....

Embodiment 2

[0031] This embodiment provides a method for cooperating with copper smelting to process domestic waste incineration fly ash, which mainly includes the following steps:

[0032] Composition of a domestic waste incineration plant: CaO 32.74%, Al 2 o 3 1.55%, SiO 2 8.79%, K 2 O4.67%, Na 2 O 4.84%, Cl 14.12%. The above garbage incineration fly ash was taken, washed with water at 30°C for 0.5 hour, and dried at 80°C for 1 hour. Composition of fly ash after water washing: CaO 41.95%, Al 2 o 3 2.43%, SiO 2 14.24%, K 2 O 0.25%, Na 2 O 0.40%, Cl 0.42%.

[0033] During the copper smelting process, the composition of the copper concentrate fed into the furnace is 25.90% Cu, 24.51% Fe, 33.27% S, 6.15% Zn, and 2.25% Pb. Add 0.1 tons of fly ash to 1 ton of concentrate (mass ratio of waste incineration fly ash to copper concentrate is 1:10), and smelt at 1400°C. Dioxins are completely decomposed and 0.58 tons of slag is produced. The composition of the obtained matte is: CuS6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com