Preparation for degrading printing and dyeing pollution in natural fabric and preparation method of preparation

A technology of natural plants and preparations, applied in plant fibers, animal fibers, textiles and papermaking, etc., can solve the problems of environmental pollution, difficult degradation and discharge, complicated procedures, etc., and achieve simple preparation methods, good degradation effects, and wide sources of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

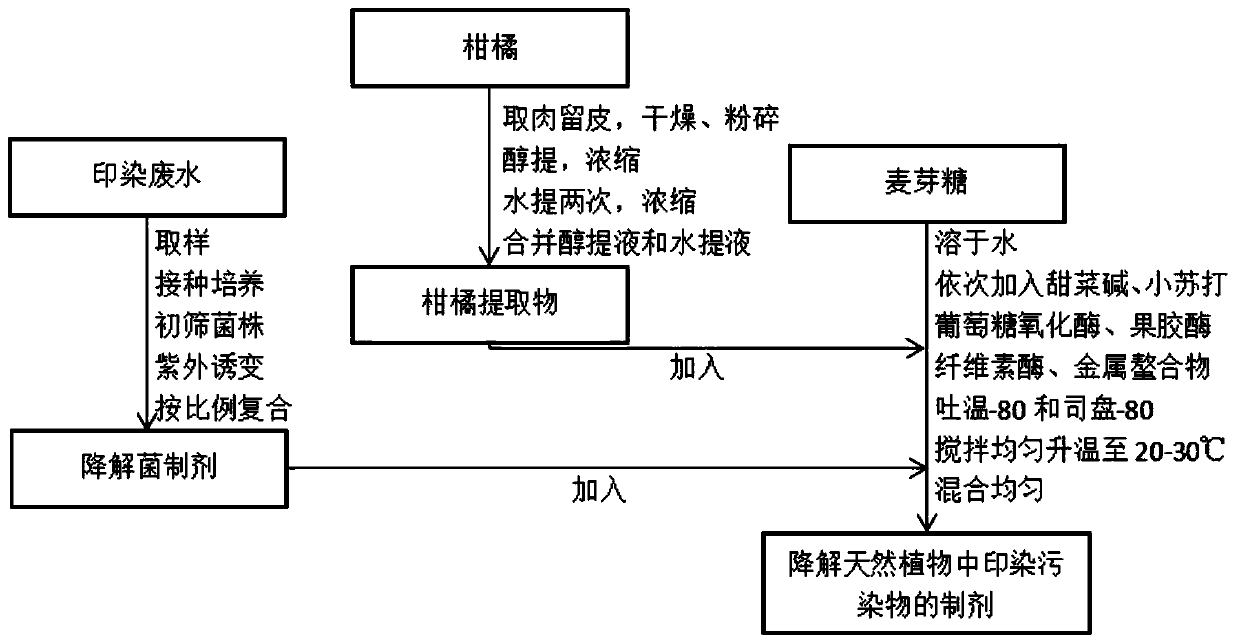

Method used

Image

Examples

Embodiment 1

[0027] Composition of raw materials (parts by weight): 10 parts of citrus extract, 5 parts of degrading bacteria preparation, 3 parts of maltose, 2 parts of betaine, 1 part of baking soda, 2 parts of glucose oxidase, 1 part of pectinase, 1 part of cellulase , 2 parts of xanthate, 1 part of Tween-80, 1 part of Span-80 and 100 parts of deionized water; the glucose oxidase is isolated from Penicillium insolens, and the pectinase is isolated from Aspergillus niger, The cellulase is isolated from alkaliphilic bacteria.

[0028] The degrading bacteria preparation is composed of the following bacteria according to colonies: 35 parts of Escherichia coli, 15 parts of Bacillus, 10 parts of Aspergillus pylorus, 5 parts of Aspergillus, 3 parts of Penicillium, 5 parts of Mycobacterium, 2 parts of Karstella and Escherichia 2 parts.

[0029] Preparation:

[0030] S1. Preparation of citrus extract: take the citrus and leave the skin, dry and pulverize, soak in ethanol solution for 2 hours, ...

Embodiment 2

[0034] Composition of raw materials (parts by weight): 20 parts of citrus extract, 15 parts of degrading bacteria preparation, 10 parts of maltose, 5 parts of betaine, 3 parts of baking soda, 5 parts of glucose oxidase, 3 parts of pectinase, 2 parts of cellulase , 5 parts of sodium dithiocarbamate, 2 parts of Tween-80, 2 parts of Span-80 and 120 parts of deionized water; Isolated, the cellulase is isolated from alkaliphilic bacteria.

[0035] The degrading bacteria preparation is composed of the following bacteria according to colonies: 35 parts of Escherichia coli, 15 parts of Bacillus, 10 parts of Aspergillus pylorus, 5 parts of Aspergillus, 3 parts of Penicillium, 5 parts of Mycobacterium, 2 parts of Karstella and Escherichia 2 parts.

[0036] Preparation:

[0037]S1. Preparation of citrus extract: take citrus and leave the skin, dry and crush, soak in ethanol solution for 4 hours, filter, collect alcohol solution, concentrate to obtain alcohol concentrate A, concentrate ...

Embodiment 3

[0041] Composition of raw materials (parts by weight): 12 parts of citrus extract, 7 parts of degrading bacteria preparation, 5 parts of maltose, 3 parts of betaine, 2 parts of baking soda, 2 parts of glucose oxidase, 2 parts of pectinase, 1.2 parts of cellulase , 2 parts of 2,2'-bipyridine disodium, 1.2 parts of Tween-80, 1.1 parts of Span-80 and 105 parts of deionized water; the glucose oxidase is isolated from Penicillium insolens, and the pectinase is isolated from niger, and the cellulase was isolated from alkaliphilic bacteria.

[0042] The degrading bacteria preparation is composed of the following bacteria according to colonies: 22 parts of Escherichia coli, 11 parts of Bacillus, 6 parts of Aspergillus pylorus, 3 parts of Aspergillus, 2 parts of Penicillium, 3 parts of Mycobacterium, 1.2 parts of Karstella and Escherichia 1.1 parts.

[0043] Preparation:

[0044] S1. Preparation of citrus extract: take citrus and leave the skin, dry and crush, soak in ethanol solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com