Environment-friendly insulation board construction method

A construction method and thermal insulation board technology, which is applied in the field of building wall thermal insulation, can solve the problems of high cost, easy falling off of the thermal insulation layer, poor durability and thermal insulation, etc., and achieve the effects of high degree of mechanization, easy construction quality, and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

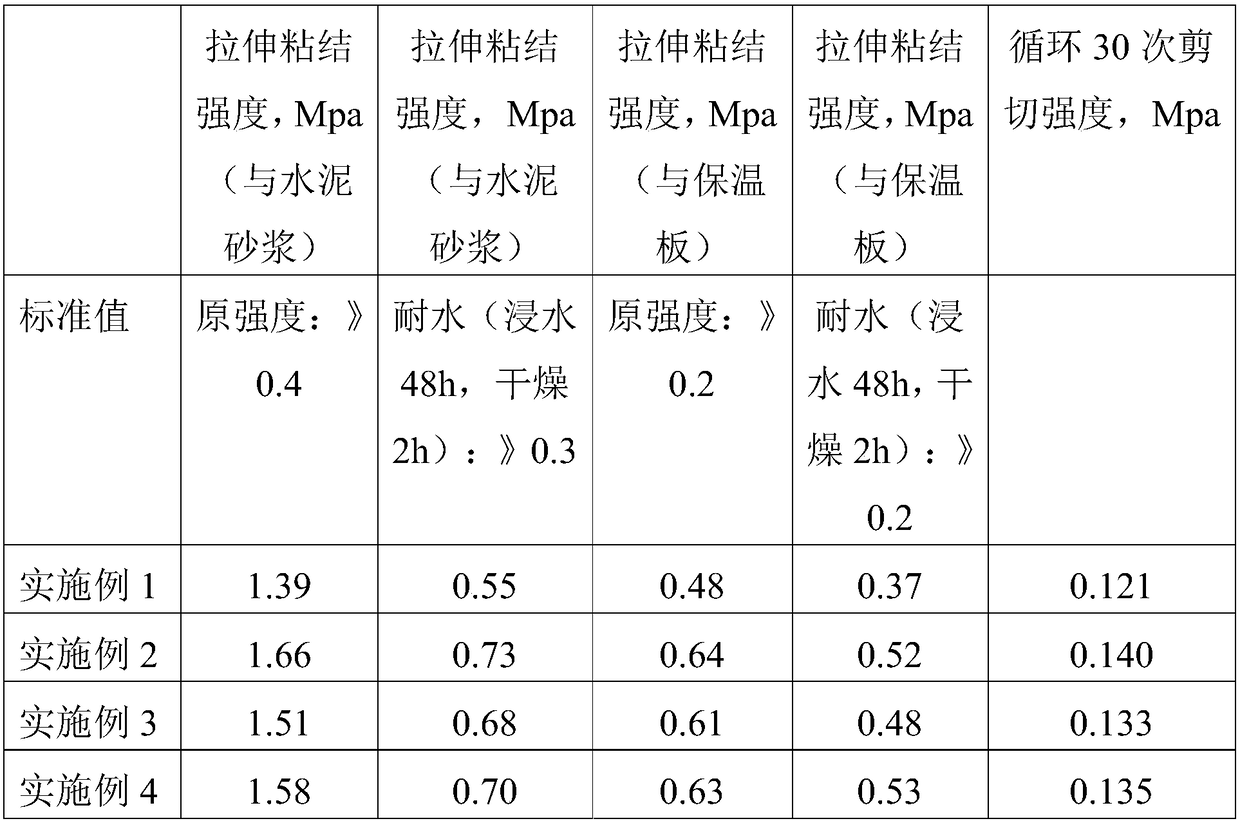

Examples

Embodiment 1

[0055] The environmental protection construction method of the insulation board comprises the following steps:

[0056] a. Surface treatment:

[0057] Remove the sundries on the base surface, repair the holes or obviously sunken parts with putty, and then use a grinder to grind the obvious protruding parts and the repaired parts to meet the requirements of 1mm / 2m;

[0058] b. Preparation of bonding mortar:

[0059] 430 parts by weight of Portland cement, 330 parts by weight of quartz sand, 10 parts by weight of hydroxypropyl guar gum, 42 parts by weight of acrylic adhesive, 6 parts by weight of sodium dodecylbenzenesulfonate, 40 parts by weight of water Magnesite fiber, 0.02 parts by weight of calcium formate, 15 parts by weight of fly ash were mixed uniformly at a speed of 150r / min for 10 minutes, and then mixed with 300 parts of water by a speed of 150r / min for 10 minutes to obtain a bonded mortar;

[0060] c. Paste the insulation board:

[0061] Hang vertical reference l...

Embodiment 2

[0063] The environmental protection construction method of the insulation board comprises the following steps:

[0064] a. Surface treatment:

[0065] Remove the sundries on the base surface, repair the holes or obviously sunken parts with putty, and then use a grinder to grind the obvious protruding parts and the repaired parts to meet the requirements of 1mm / 2m;

[0066] b. Preparation of bonding mortar:

[0067] 430 parts by weight of Portland cement, 330 parts by weight of quartz sand, 10 parts by weight of hydroxypropyl guar gum, 42 parts by weight of acrylic adhesive, 6 parts by weight of sodium dodecylbenzene sulfonate, 40 parts by weight of modified Brucite fiber, 0.02 parts by weight of calcium formate, 15 parts by weight of fly ash were mixed evenly at a speed of 150r / min for 10 minutes, and then mixed evenly with 300 parts of water at a speed of 150r / min for 10 minutes to obtain a bonded mortar ;

[0068] The preparation method of the modified brucite fiber is as...

Embodiment 3

[0072] The environmental protection construction method of the insulation board comprises the following steps:

[0073] a. Surface treatment:

[0074] Remove the sundries on the base surface, repair the holes or obviously sunken parts with putty, and then use a grinder to grind the obvious protruding parts and the repaired parts to meet the requirements of 1mm / 2m;

[0075] b. Preparation of bonding mortar:

[0076] 430 parts by weight of Portland cement, 330 parts by weight of quartz sand, 10 parts by weight of hydroxypropyl guar gum, 42 parts by weight of acrylic adhesive, 6 parts by weight of sodium dodecylbenzene sulfonate, 40 parts by weight of modified Brucite fiber, 0.02 parts by weight of calcium formate, 15 parts by weight of fly ash were mixed evenly at a speed of 150r / min for 10 minutes, and then mixed evenly with 300 parts of water at a speed of 150r / min for 10 minutes to obtain a bonded mortar ;

[0077] The preparation method of the modified brucite fiber is as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com