Method for preparing diamond abrasive tool with orderly arrangement of abrasive grains by using mask plate

A technology of diamond and mask, which is applied in the direction of manufacturing tools, grinding devices, metal processing equipment, etc., can solve the problem of poor manufacturability and difficulty in realizing the single-layer brazing of fine-grained diamond abrasives. Welding and brazing bond layer thickness and other problems, to achieve the effect of good consistency of exposed height, conducive to mass production, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

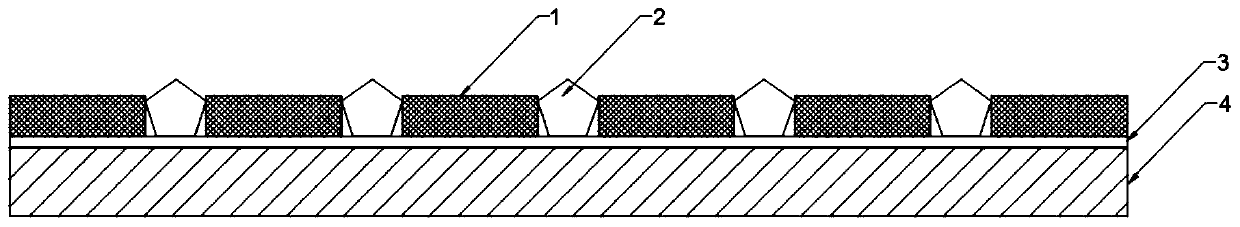

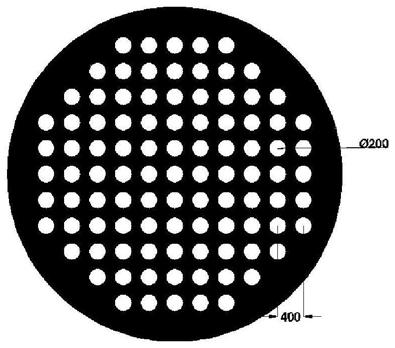

[0044] The substrate is silicon carbide ceramics, the abrasive is 100-mesh diamond powder, the thickness of the mask plate is 150 μm, and the surface is etched with a matrix-shaped through-hole array arranged in an orderly manner, and the diameter of the through-hole is 200 μm.

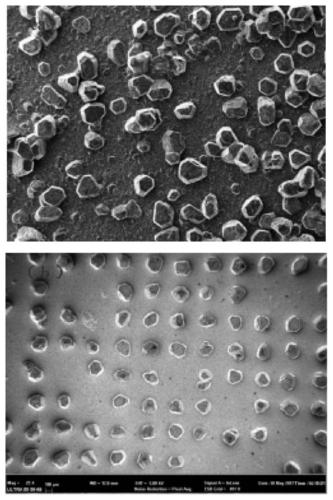

[0045] The surface of the substrate was ground with 15 μm diamond micropowder for 1 min, and then the substrate was ultrasonically cleaned with acetone. Then coat the photoresist on the surface of the substrate, and stick the mask on the surface of the substrate. Then, the diamond powder is spread on the mask, and the substrate is fully vibrated, so that each hole of the mask is filled with a single diamond grain. The excess diamond grit is then wiped off and the mask is removed. The orderly arranged diamond abrasive grains are fixed on the surface of the substrate. Then, the diamond coating is deposited on the surface of the substrate by hot wire chemical vapor deposition equipment, and the abrasiv...

Embodiment 2

[0050] The substrate is cemented carbide, the abrasive is 100-mesh diamond powder, the thickness of the mask plate is 150 μm, and the surface is etched with a matrix-shaped through-hole array arranged in an orderly manner, and the diameter of the through-hole is 200 μm.

[0051] The cemented carbide substrate is pretreated with acid and alkali, and the cemented carbide substrate is first immersed in Murakami solution (10g K 3 [Fe(CN)] 6 +10g KOH+100mL H 2 O) in ultrasonic treatment for 30min, then soak it in mixed acid (HCl: H 2 o 2 =1:3) for 1 minute to remove the cobalt element on the surface, and then clean the surface of the substrate with acetone. Then coat the photoresist on the surface of the substrate, and stick the mask on the surface of the substrate. Then the diamond powder is spread on the mask, and the tool substrate is fully vibrated, so that each hole of the mask is filled with a single diamond grain. The excess diamond grit is then wiped off and the mask i...

Embodiment 3

[0054] The substrate is silicon carbide, the abrasive is 170-mesh diamond powder, the thickness of the mask is 100 μm, and the surface is etched with a matrix-shaped through-hole array arranged in an orderly manner, the diameter of the through-holes is 100 μm, and the spacing is 200 μm.

[0055] The surface of the substrate was ground with 15 μm diamond powder for 1 min, and then the substrate was ultrasonically cleaned with acetone. Then coat the photoresist on the surface of the substrate, and stick the mask on the surface of the substrate. Then, the diamond powder is spread on the mask, and the substrate is fully vibrated, so that each hole of the mask is filled with a single diamond grain. The excess diamond grit is then wiped off and the mask is removed. The orderly arranged diamond abrasive grains are fixed on the surface of the substrate. Then, the diamond coating is deposited on the surface of the substrate by hot wire chemical vapor deposition equipment, and the abr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com