Method for constructing polymer brush on surface of material

A technology of polymer brush and polydopamine, which is applied in the direction of coating, etc., can solve the problems of difficult modification of materials, complicated oxygen removal steps, not cost-effective, etc., and achieve the effect of overcoming toxicity problems and strong universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

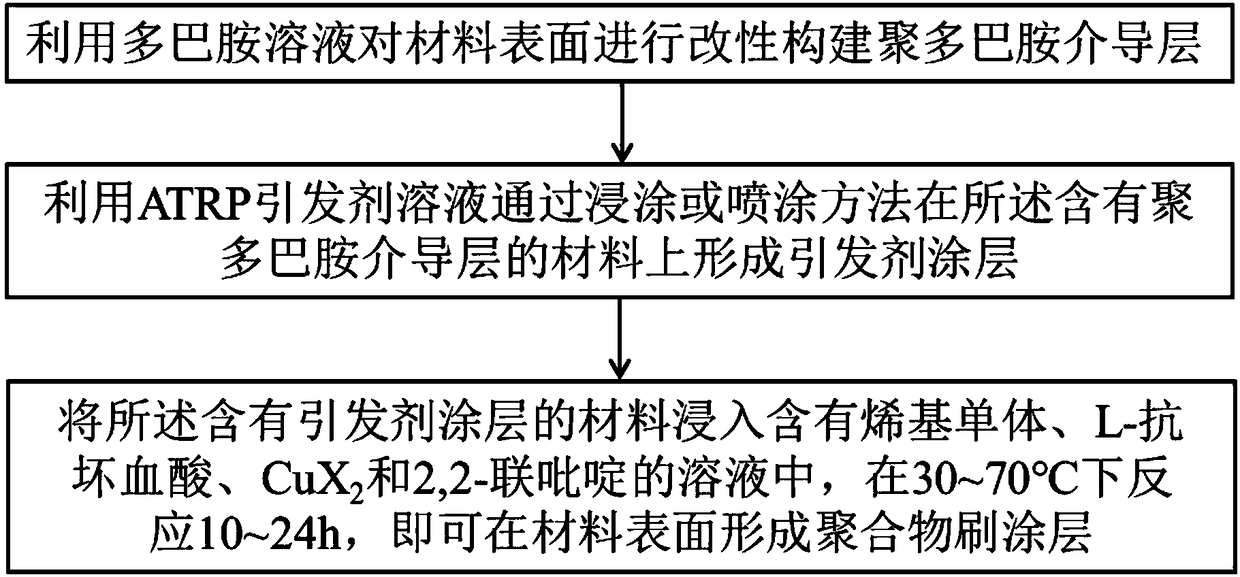

[0030] Such as figure 1 Shown, the method for constructing polymeric brush on material surface described in the present invention, comprises the following steps:

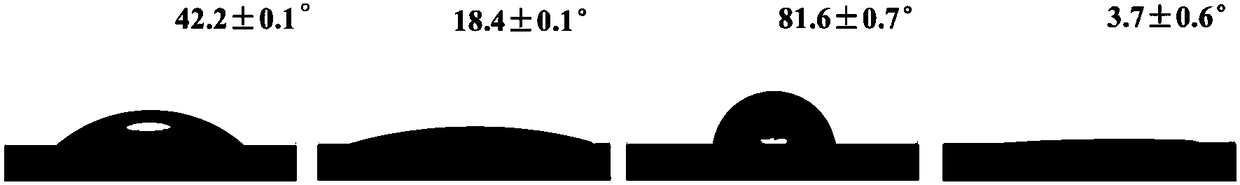

[0031] 1. Prepare a dopamine aqueous solution (pH 8.3) with a concentration of 2mg / mL, and distill 1.5×1.5cm 2 Immerse the glass sheet in the above solution for 12 hours, rinse and dry at room temperature to obtain a glass sheet containing a polydopamine mediation layer. The average static contact angle is 18.4±0.1°, which is significantly lower than the static contact angle of the blank glass sheet. Contact angle 42°;

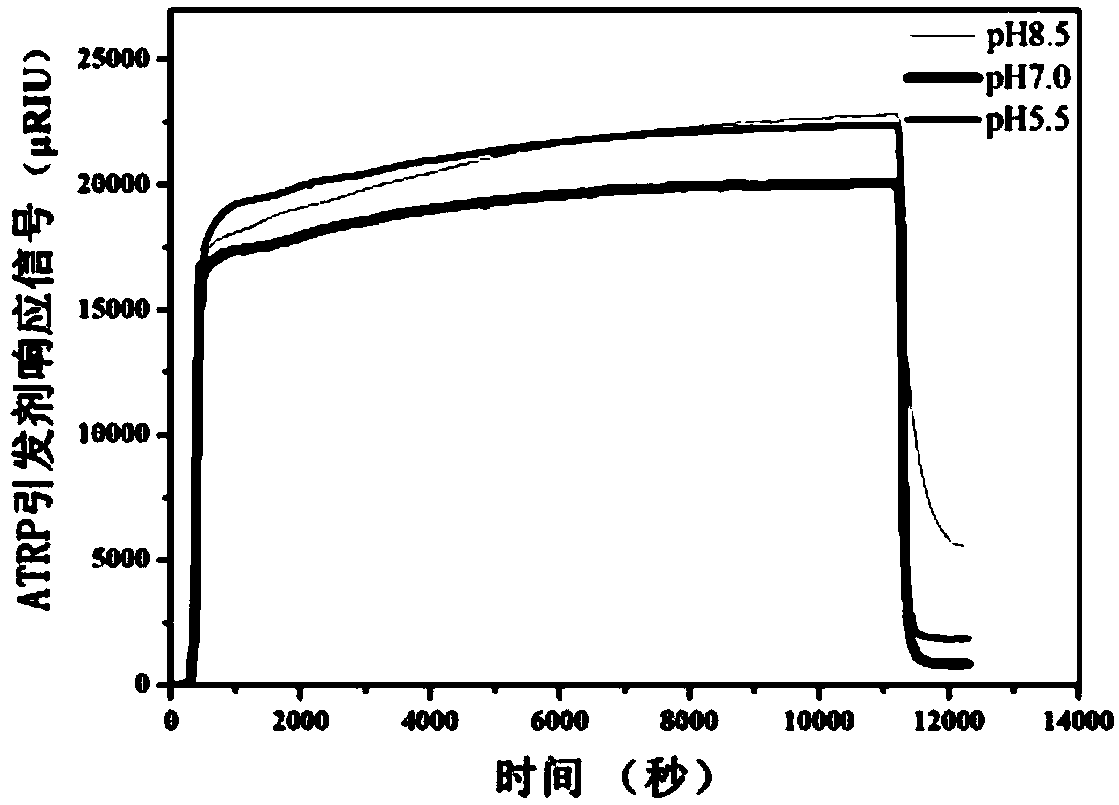

[0032] 2. Soak the glass sheet obtained in step 1 in the PBS (pH8.5) of 2mg / mL ATRP initiator: ethanol=1:1 (V / V) mixed solution, dip-coat at room temperature for 12h, rinse with ethanol Dry to obtain the glass flake that contains initiator coating, record its static contact angle and be 81.6 ± 0.7 °, compared with the glass flake that contains polydopamine intermediary layer, there has been obviou...

Embodiment 2

[0035] 1. Prepare a dopamine aqueous solution (pH 8.3) with a concentration of 8 mg / mL, and place 1.5 × 1.5 cm 2 The glass sheet was soaked in the above solution for 3h, rinsed and dried at room temperature to obtain a glass sheet containing a polydopamine mediation layer;

[0036] 2. Soak the glass sheet obtained in step 1 in the PBS (pH8.5) of 4mg / mL ATRP initiator: ethanol=1:1 (V / V) mixed solution, dip-coat at room temperature for 12h, rinse with ethanol Dry to obtain the glass flake that contains initiator coating;

[0037] 3. soak the glass flake containing the initiator coating obtained in step 2 in a solution containing 40mg / mL MPC, 6mg / mL L-ascorbic acid, 0.006mg / mL CuBr 2 , 0.0152mg / mL Bpy in PBS (pH 7.4) solution, reacted at 60°C for 12h under airtight conditions, rinsed with water and dried to obtain a glass sheet containing polymer brush coating, the static contact angle was 0°, and Significantly lower compared to glass flakes containing initiator coatings.

Embodiment 3

[0039] 1. Prepare a dopamine aqueous solution (pH 8.3) with a concentration of 0.5mg / mL, and place 1.5×1.5cm 2 The glass flakes were dipped in the above solution for 24 hours, rinsed and dried at room temperature to obtain glass flakes containing a polydopamine mediation layer;

[0040] 2. Soak the glass sheet obtained in step 1 in PBS (pH7.4): ethanol = 1:1 (V / V) mixed solution containing 1 mg / mL dopamine, 2 mg / mL ATRP initiator, and dip-coat at room temperature for 12 hours , rinsed with ethanol and dried to obtain a glass sheet containing an initiator coating;

[0041] 3. soak the glass sheet containing the initiator coating obtained in step 2 in a solution containing 20mg / mL MPC, 6mg / mL L-ascorbic acid, 0.0036mg / mL CuBr 2 , 0.0152mg / mL Bpy in PBS (pH 7.4) solution, reacted at 30°C for 12h under open conditions, rinsed with water and dried to obtain a glass sheet containing polymer brush coating, and its static contact angle was 5.0±0.6° , which is significantly lower tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com