High-damping concrete with high-strength high-elasticity modulus

A high-elasticity, high-damping technology, applied in climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problem of inability to adopt seismic isolation measures, save related costs and speed up the development process , the effect of reducing the likelihood and degree of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

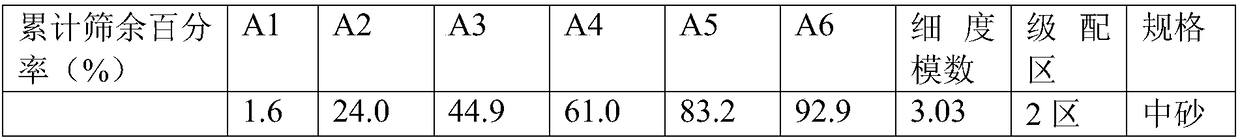

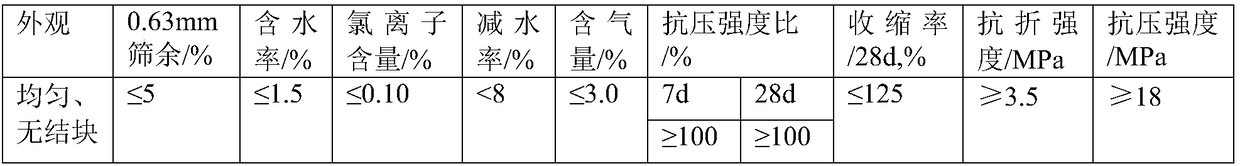

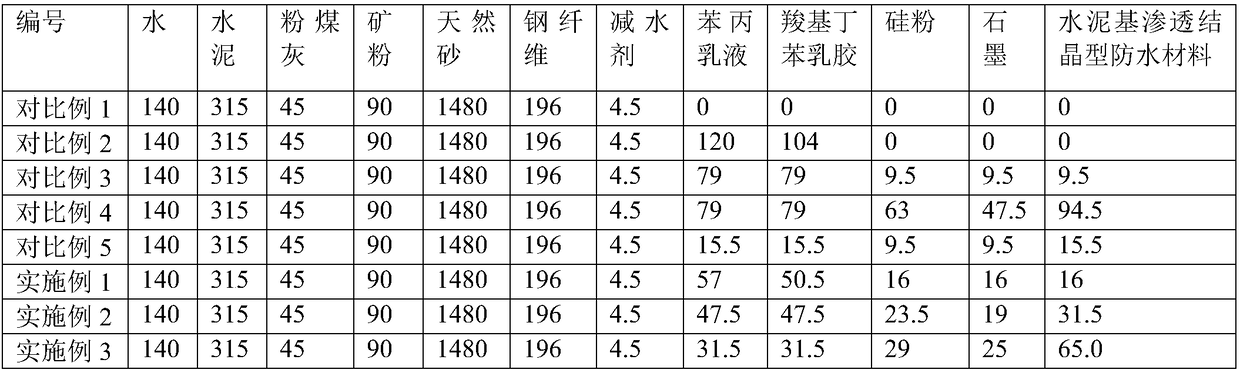

[0045] A high-strength, high-elastic-modulus high-damping concrete whose proportioning conditions are shown in Table 3, and the specific preparation steps are as follows:

[0046] 1) Weigh each raw material according to the proportion, and before concrete mixing, first wipe the mold clean, remove the sundries in the mold, and apply a layer of release agent in the mold;

[0047] 2) Mix the weighed natural sand, cement, fly ash, mineral powder, silicon powder, graphite, cement-based permeable crystalline waterproof material and stir for 30s with a forced mixer to make the cement and other solid materials uniform in the aggregate For distribution, add water, water reducer, styrene-acrylic emulsion, carboxylated styrene-butadiene latex and stir for 2 minutes, and finally add steel fiber and stir for 30 seconds to obtain a concrete mixture;

[0048] 3) The obtained concrete mixture is divided into two layers, each layer is about 1 / 2, and each layer is inserted and rammed about 2 to...

Embodiment 2

[0052] The preparation method of the high damping concrete described in Example 2 is roughly the same as that of Example 1, except that the formula conditions recorded in Table 2 are used respectively, and the strength grade of the obtained concrete is C40.

Embodiment 3

[0054] The preparation method of the high damping concrete described in Example 3 is roughly the same as that of Example 1, except that the formula conditions recorded in Table 2 are used respectively, and the strength grade of the obtained concrete is C40.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com