A kind of product refining method of epichlorohydrin prepared by propylene chloride epoxidation method

A technology of epichlorohydrin and refining method, which is applied in the field of separation and purification of chemical substances, and can solve problems such as difficult separation, quality decline of 3-chloropropene, and impact on the quality of crude epichlorohydrin rectification epichlorohydrin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

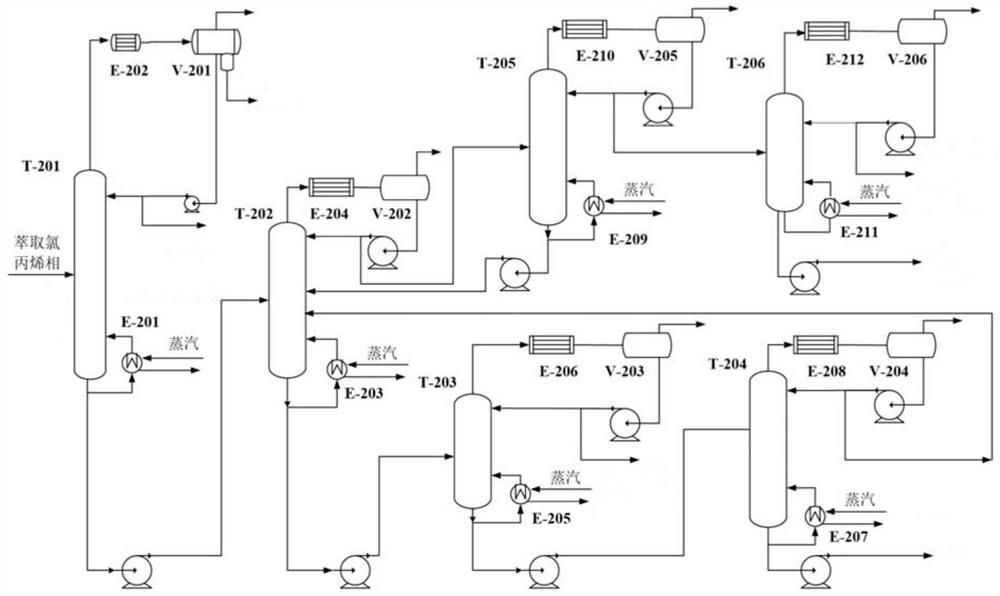

Image

Examples

Embodiment 1

[0029]The main component content of the 3-chloropropene raw material used in this example is 99.511% of 3-chloropropene, 0.278% of 1-chloropropane, and 0.105% of 1,5-hexadiene; prepared by epoxidation of chloropropene After the reaction distillate of epichlorohydrin is extracted, the main component content of the extract phase is 88.804% of 3-chloropropene, 0.305% of 1-chloropropane, and 10.357% of ECH. According to an annual output of 50,000 tons of ECH scale, the specific method for preparing epichlorohydrin by epoxidation of propylene chloride is as follows:

[0030] After the reaction distillate prepared by epoxidation of propylene chloride is extracted, the extract phase is transported to the dealcoholization deenification tower T-201 at a flow rate of 60500 kg / hr. The main part of the dealcoholization deenification tower T-201 The function is to rectify the reaction material 3-chloropropene, remove 1-chloropropane, hexadiene, alcohols and epichlorohydrin, etc., and make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com