A kind of heat insulation masterbatch and bopet window film and preparation method

A technology of masterbatch and window film, which is applied in the field of window film, can solve the problems of light transmittance and mechanical property decline, light transmittance influence, poor compatibility and dispersion of matrix resin, etc., to improve light absorption efficiency and heat insulation effect , Improve the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

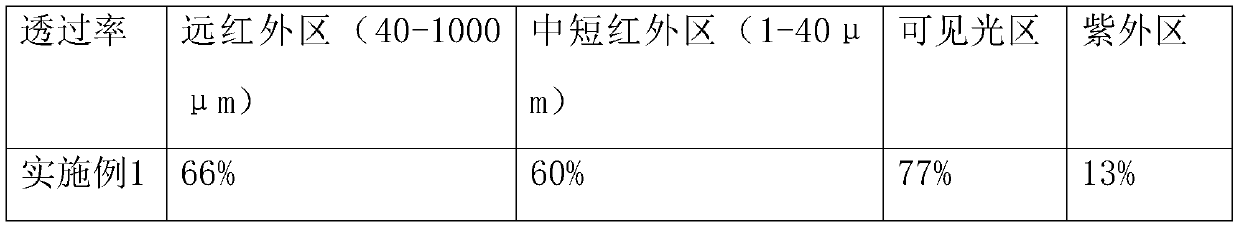

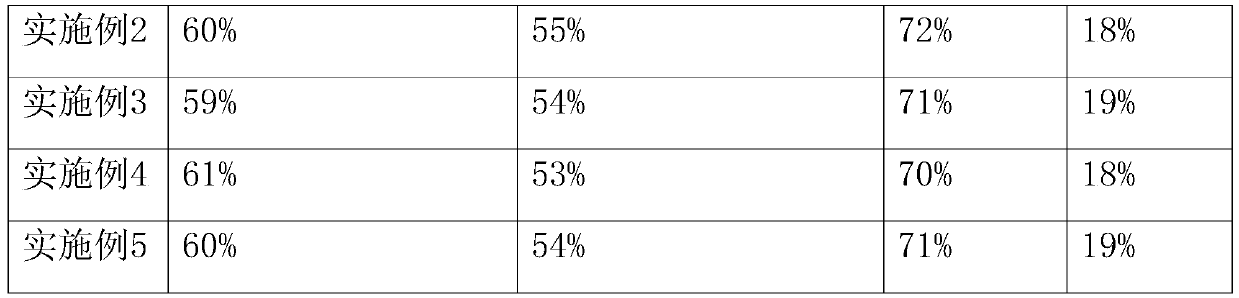

Examples

Embodiment 1

[0036] A heat-insulating masterbatch, comprising the following raw materials in parts by weight:

[0037] 40 parts polyester resin

[0038] Heat insulation composition 15 parts

[0039] Dispersant 0.5 parts

[0040] Wherein, the thermal insulation composition is a core-inner-shell-outer structure composition, the core of which is nano-carbonized cellulose, the inner shell is a titanium dioxide layer, and the outer shell is a polyacrylamide layer.

[0041] Wherein, the preparation method of the heat insulating composition comprises the steps of:

[0042] A, adding 4 parts by weight of nanocellulose to 30 parts by weight of an aqueous ethanol solution with a volume concentration of 95% for ultrasonic dispersion to obtain a dispersion;

[0043] B. Add 15 parts by weight of butyl titanate to the dispersion, heat up to 85° C. to hydrolyze it, and obtain nanocellulose / titanium dioxide microspheres;

[0044] C. After the nanocellulose / titanium dioxide microspheres are placed in a...

Embodiment 2

[0060] A heat-insulating masterbatch, comprising the following raw materials in parts by weight:

[0061] 30 parts polyester resin

[0062] 12 parts heat insulation composition

[0063] Dispersant 0.1 parts

[0064] Wherein, the thermal insulation composition is a core-inner-shell-outer structure composition, the core of which is nano-carbonized cellulose, the inner shell is a titanium dioxide layer, and the outer shell is a polyacrylamide layer.

[0065] Wherein, the preparation method of the heat insulating composition comprises the steps of:

[0066] A, adding 2 parts by weight of nanocellulose to 25 parts by weight of an aqueous ethanol solution with a volume concentration of 92% for ultrasonic dispersion to obtain a dispersion;

[0067] B. Add 12 parts by weight of butyl titanate to the dispersion, heat up to 80° C. to hydrolyze it, and obtain nanocellulose / titanium dioxide microspheres;

[0068] C. After the nanocellulose / titanium dioxide microspheres are placed in a...

Embodiment 3

[0085] A heat-insulating masterbatch, comprising the following raw materials in parts by weight:

[0086] 50 parts polyester resin

[0087] Heat insulation composition 18 parts

[0088] 1 part dispersant

[0089] Wherein, the thermal insulation composition is a core-inner-shell-outer structure composition, the core of which is nano-carbonized cellulose, the inner shell is a titanium dioxide layer, and the outer shell is a polyacrylamide layer.

[0090] Wherein, the preparation method of the heat insulating composition comprises the steps of:

[0091] A, adding 6 parts by weight of nanocellulose to 35 parts by weight of an aqueous ethanol solution with a volume concentration of 98% for ultrasonic dispersion to obtain a dispersion;

[0092] B. Add 18 parts by weight of butyl titanate to the dispersion, heat up to 90° C. to hydrolyze it, and obtain nanocellulose / titanium dioxide microspheres;

[0093] C. After the nanocellulose / titanium dioxide microspheres are placed in an i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com