Coating

A paint and oil-based paint technology, applied in the paint field, can solve the problems of short afterglow time, shortage of luminous materials, weak luminous intensity, etc., and achieve the effects of long afterglow time, enhanced afterglow brightness and time, and high afterglow brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

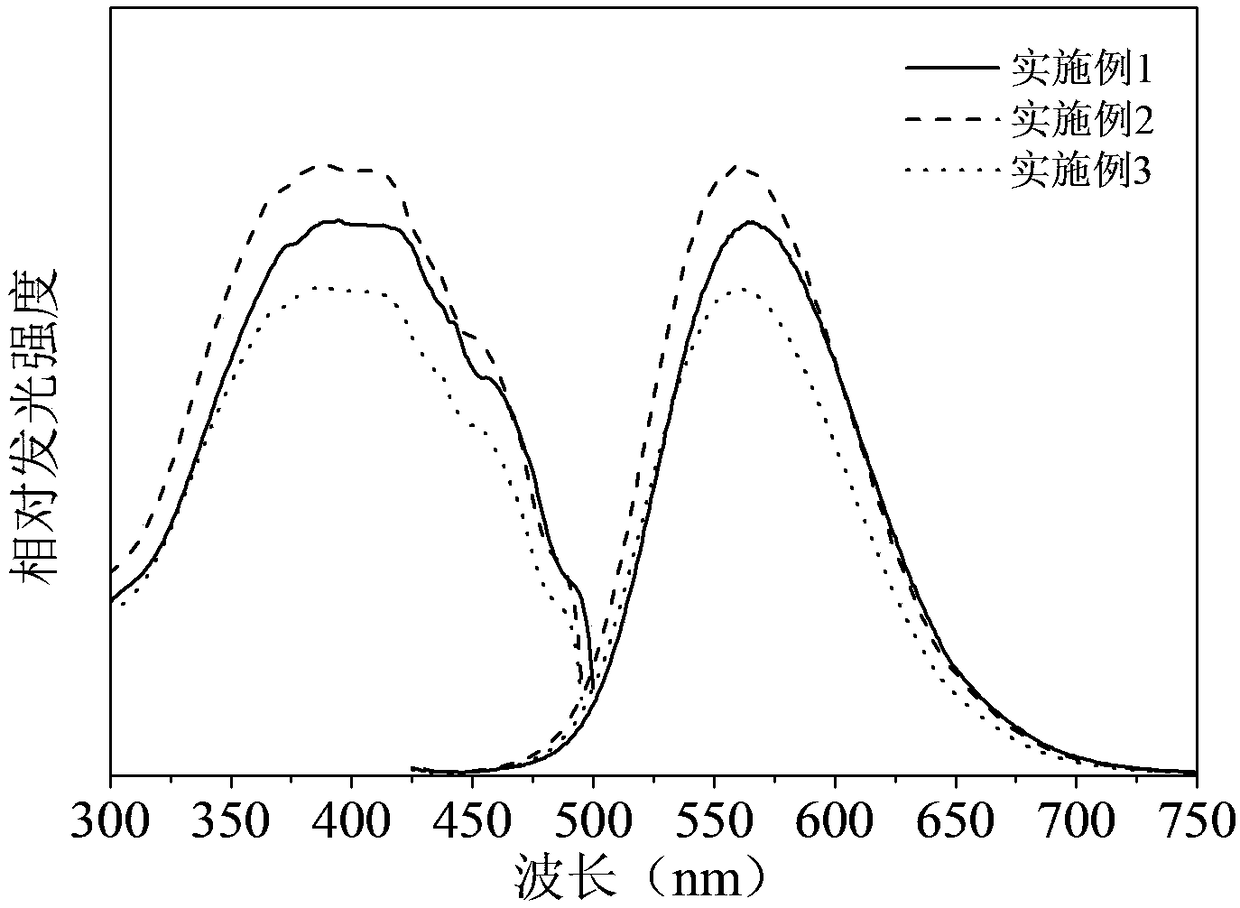

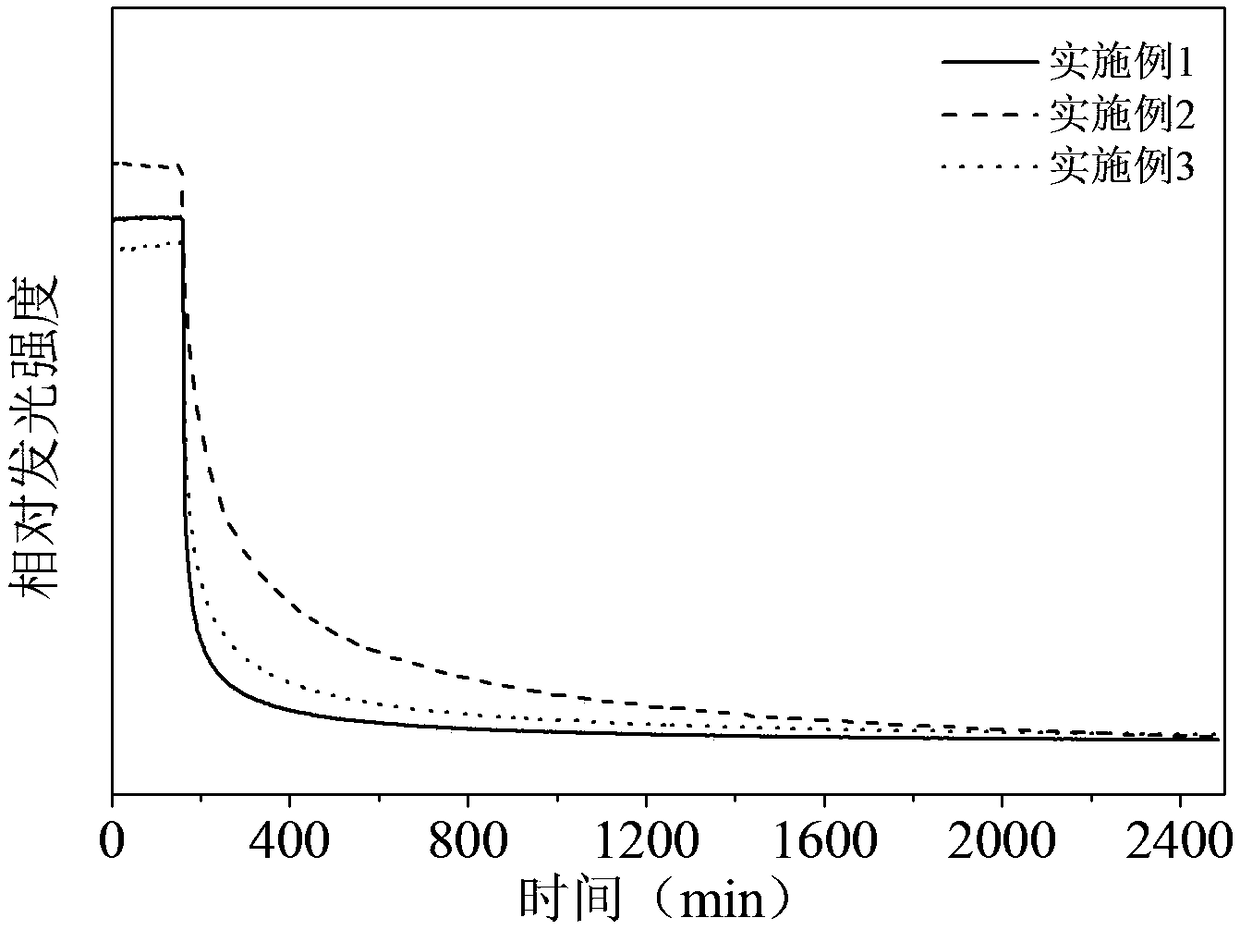

Embodiment 1

[0123] A yellow long-lasting phosphor with a chemical composition of Sr 4.94 SiB 2 o 10 : 0.04Eu 2+ , 0.02Dy 3+ , with high-purity SrCO 3 , SiO 2 、H 3 BO 3 、Eu 2 o 3 and Dy 2 o 3 As a raw material, according to the chemical composition general formula Sr 4.94 SiB 2 o 10 : 0.04Eu 2+ ,0.02Dy 3+ The ratio of each element in the formula, accurately weigh each raw material; put each raw material into an agate mortar at the same time, and mix them evenly by manual grinding, and the grinding time of each sample is 20min; the above-mentioned uniformly mixed raw materials Put it into a corundum crucible and sinter it in a high-temperature tube furnace. The sintering temperature is 1200°C, the sintering time is 4 hours, the heating rate is 10°C / min, and the sintering atmosphere is 5%H 2 / 95%N 2 After the sintering is completed, it is cooled to room temperature with the furnace to obtain a sintered body; the obtained sintered body is ground and pulverized to obtain the y...

Embodiment 2

[0125] A yellow long-lasting phosphor with a chemical composition of Sr 4.96 SiB 2 o 10 : 0.02Eu 2+ , 0.02Gd 3+ , with high-purity SrCO 3 , SiO 2 、H 3 BO 3 、Eu 2 o 3 and Gd 2 o 3 As a raw material, according to the chemical composition general formula Sr 4.96 SiB 2 o 10 : 0.02Eu 2+ ,0.02Gd 3+ The ratio of each element in the formula, accurately weigh each raw material; put each raw material into an agate mortar at the same time, and mix them evenly by manual grinding, and the grinding time of each sample is 30min; the above-mentioned uniformly mixed raw materials Put it into a corundum crucible and sinter it in a high-temperature tube furnace. The sintering temperature is 1400°C, the sintering time is 6 hours, the heating rate is 10°C / min, and the sintering atmosphere is 5%H 2 / 95%N 2 After the sintering is completed, it is cooled to room temperature with the furnace to obtain a sintered body; the obtained sintered body is ground and pulverized to obtain the y...

Embodiment 3

[0127] A yellow long-lasting phosphor with a chemical composition of Sr 4.98 SiB 2 o 10 : 0.01Eu 2+ , 0.01La 3+ , with high-purity SrCO 3 , SiO 2 、H 3 BO 3 、Eu 2 o 3 and La 2 o 3 As a raw material, according to the chemical composition general formula Sr 4.98 SiB 2 o 10 : 0.01Eu 2+ ,0.01La 3+ The ratio of each element in the formula, accurately weigh each raw material; put each raw material into an agate mortar at the same time, and mix them evenly by manual grinding, and the grinding time of each sample is 25min; the above-mentioned uniformly mixed raw materials Put it into a corundum crucible and sinter it in a high-temperature tube furnace, the sintering temperature is 1000°C, the sintering time is 5 hours, the heating rate is 10°C / min, and the sintering atmosphere is 5%H 2 / 95%N 2 After the sintering is completed, it is cooled to room temperature with the furnace to obtain a sintered body; the obtained sintered body is ground and pulverized to obtain the y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com