Biomass gasification power generation system

A power generation system and biomass technology, applied in the direction of gasification process, fuel oil system, gaseous engine fuel, etc., can solve the problems of complex power generation process and large water consumption, reduce water consumption, reduce operating costs, and increase water reserve Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

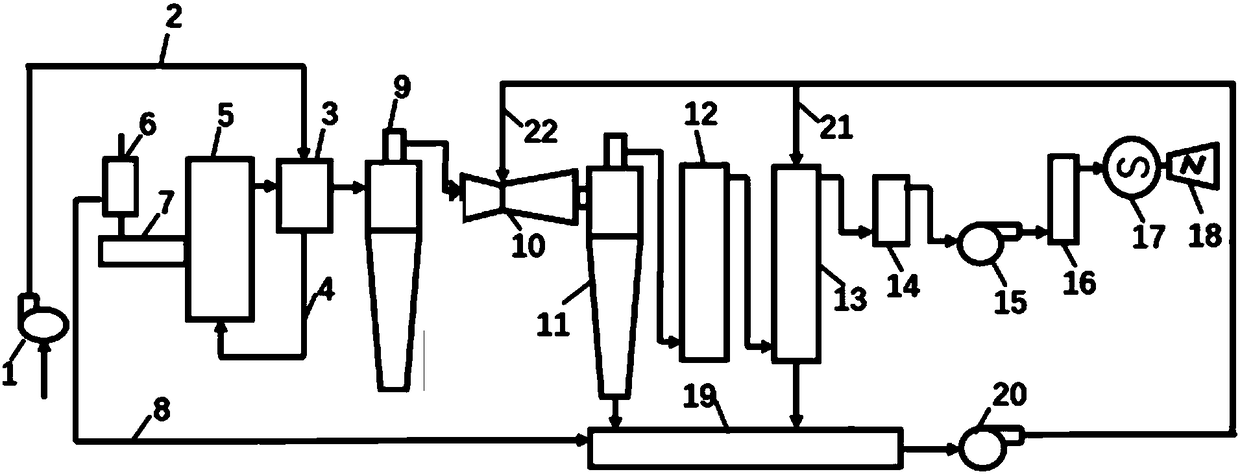

[0019] see figure 1 , this implementation provides a biomass gasification power generation system, specifically: a predryer 6, a biomass treatment equipment 7, and a gasifier 5 are connected in sequence, and the fan 1 passes through the inlet of the air supply cold air pipe 2 and the heat exchanger 3 Connect, the outlet of heat exchanger 3 is connected with the inlet of gasifier 5 through air supply hot air pipe 4, and the outlet of gasifier 5 is connected with cyclone dust collector 9 through pipeline through heat exchanger 3, cyclone dust collector 9, Venturi dust collector 10, post-venturi cyclone dust collector 11, adsorber 12, scrubber 13, dryer 14, induced draft fan 15, gas storage tank 16, internal combustion engine 17, generator 18 are connected in sequence; Water pipe 8 is connected with water purification tank 19;

[0020] like figure 1 As shown, the biomass fuel enters the pre-dryer 6 for drying, and the water generated in the pre-dryer 6 enters the water purifica...

Embodiment 2

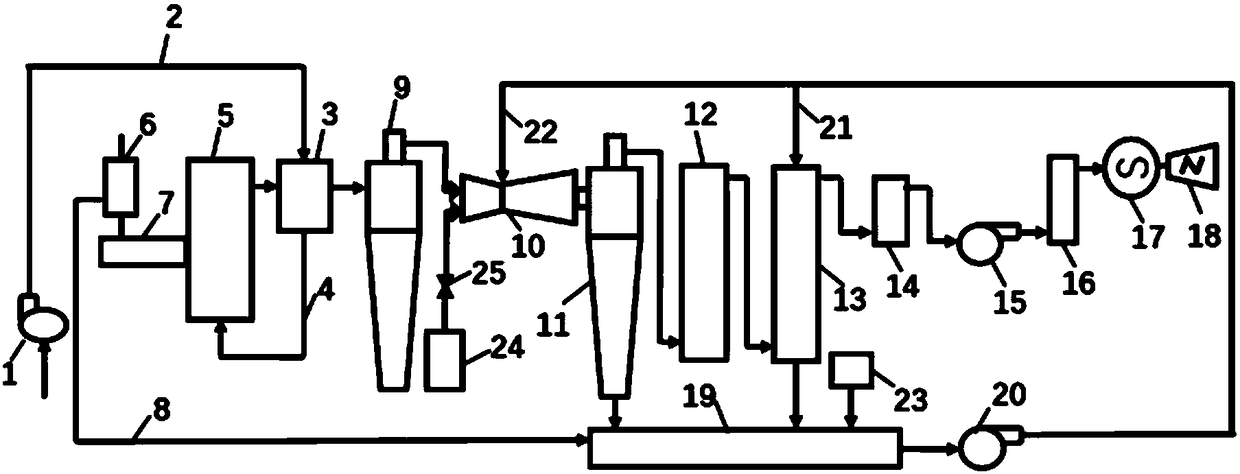

[0030] See figure 2 , present embodiment has increased natural rainwater collector 23 on the basis of embodiment 1, biogas pit 24, gas valve 25, owing to increased biogas pit, the organic matter that collects can be put into biogas pit 24, if encounter When the biomass supply is insufficient or the equipment needs to be maintained, open the gas valve 25, and the biogas in the biogas tank 24 can provide a certain amount of gas supply for the internal combustion engine 17; cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com