Packaging paper with papery weaving effect

A wrapping paper and paper technology, applied in the directions of wrapping paper, wrapping paper, packaging, etc., can solve the problems that the appearance effect is limited to the plane effect, the design is cumbersome, and the ornamental value is low, and the three-dimensional appearance effect, the design is simple and generous, and the viewing high value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

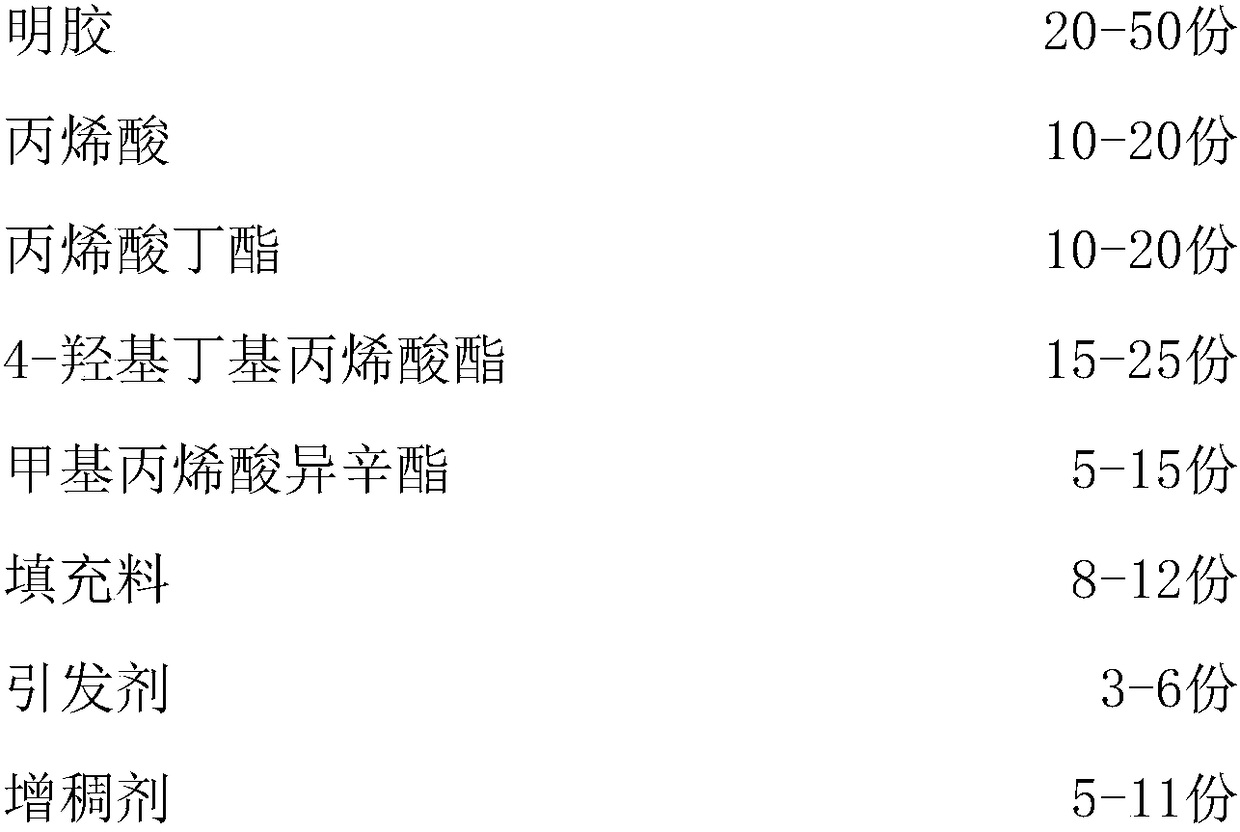

[0027] A paper wrapping paper with weaving effect, comprising a paper base layer, an adhesive layer and a weaving layer compounded sequentially from bottom to top, the weaving layer is made of strip-shaped paper strips interlaced, and the adhesive layer is made of environmentally friendly Adhesive is solidified, and described environment-friendly adhesive comprises the raw material of following parts by weight:

[0028]

[0029]

[0030] Wherein, the filler is composed of micron-scale composite microspheres and nano lignin in a weight ratio of 1:1, the micron-scale composite microspheres are core-shell microspheres, and the core of the core-shell structure microspheres is nano-red Phosphorus, the shell is microcrystalline cellulose.

[0031] Wherein, the preparation method of described micron-scale composite microsphere comprises the following steps:

[0032] A. At a temperature of 85°C, dissolve microcrystalline cellulose in an ionic liquid at a mass ratio of 8:100 to ...

Embodiment 2

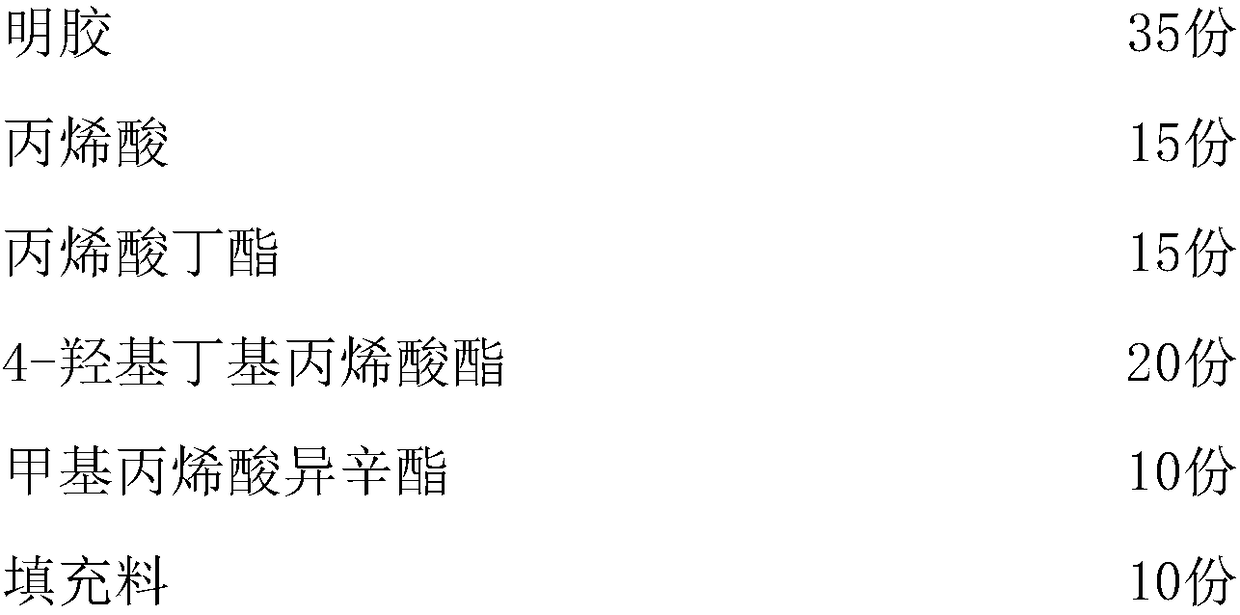

[0043] A paper wrapping paper with weaving effect, comprising a paper base layer, an adhesive layer and a weaving layer compounded sequentially from bottom to top, the weaving layer is made of strip-shaped paper strips interlaced, and the adhesive layer is made of environmentally friendly Adhesive is solidified, and described environment-friendly adhesive comprises the raw material of following parts by weight:

[0044]

[0045] Wherein, the filler is composed of micron-scale composite microspheres and nano lignin in a weight ratio of 1:3, the micron-scale composite microspheres are core-shell microspheres, and the core of the core-shell structure microspheres is nano-red Phosphorus, the shell is microcrystalline cellulose.

[0046] Wherein, the preparation method of described micron-scale composite microsphere comprises the following steps:

[0047] A. At a temperature of 80°C, dissolve microcrystalline cellulose in an ionic liquid at a mass ratio of 6:100 to form a micro...

Embodiment 3

[0058] A paper wrapping paper with weaving effect, comprising a paper base layer, an adhesive layer and a weaving layer compounded sequentially from bottom to top, the weaving layer is made of strip-shaped paper strips interlaced, and the adhesive layer is made of environmentally friendly Adhesive is solidified, and described environment-friendly adhesive comprises the raw material of following parts by weight:

[0059]

[0060] Wherein, the filler is composed of micron-scale composite microspheres and nano lignin in a weight ratio of 3:1, the micron-scale composite microspheres are core-shell microspheres, and the core of the core-shell structure microspheres is nano-red Phosphorus, the shell is microcrystalline cellulose.

[0061] Wherein, the preparation method of described micron-scale composite microsphere comprises the following steps:

[0062] A. At a temperature of 90°C, dissolve microcrystalline cellulose in an ionic liquid at a mass ratio of 10:100 to form a micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com