A built-in neutron element analysis device

A technology for neutron elements and analysis devices, which is applied in measurement devices, analysis materials, material analysis using wave/particle radiation, etc. The effect of reducing the interference ratio, reducing the interference noise, and reducing the installation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific examples.

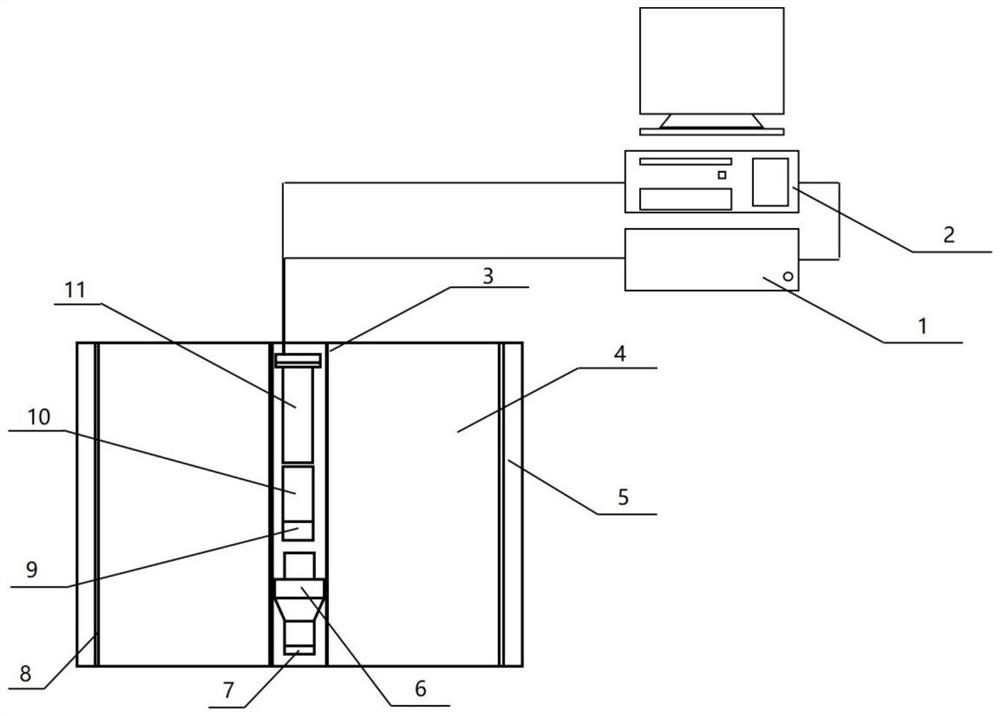

[0024] Such as figure 1 The built-in neutron elemental analysis device shown includes a neutron source term system, a sample detection system, a shielding protection system and an energy spectrum analysis system. The neutron source item system includes a neutron generator 11, a neutron generator power supply control cabinet 1, a sample detection system includes a tested sample 4, an outer barrel 8, an inner barrel 3, and a gamma ray detector 6, and the energy spectrum analysis system includes multiple The channel analyzer 7 and the industrial control computer 2, the shielding protection system includes a gamma ray shielding layer 9, a detector protection layer 10 and an environment protection layer 5.

[0025] The neutron generator 11 is a D-T neutron generator, the output neutron energy is 14MeV, and the output direction is 4π direction, which is located above the inner barr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com