Design Method of Orbital Angular Momentum Vortex Electromagnetic Wave Generator

A technology of vortex electromagnetic wave and orbital angular momentum, applied in electrical components, antennas, geometric CAD, etc., can solve problems such as the complex structure of the rotating phase plate, achieve low price, tight connection, and reduce industrial manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

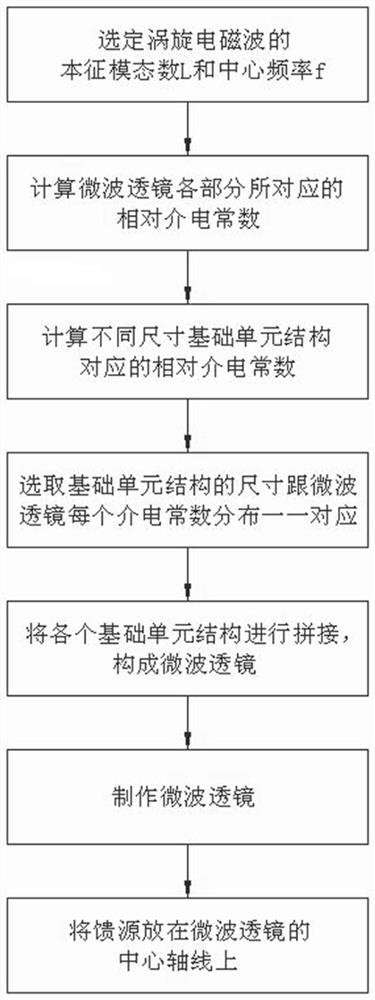

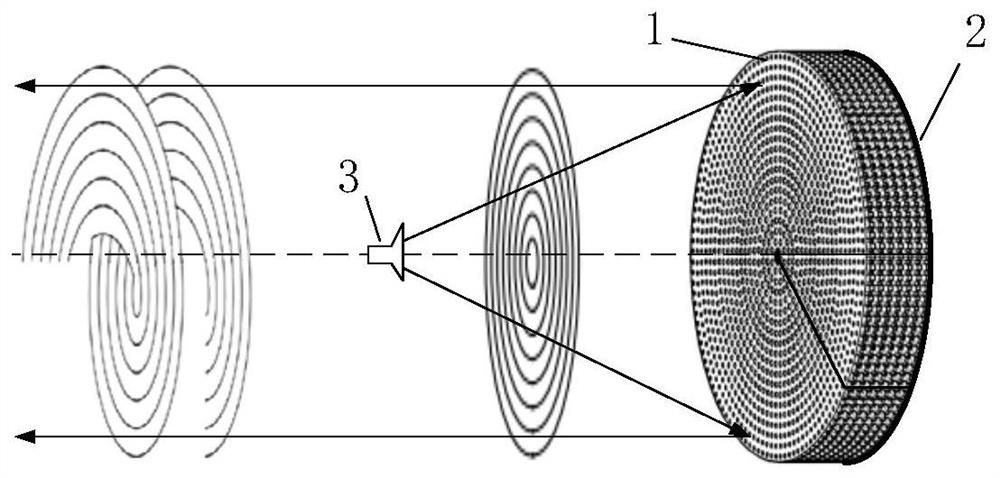

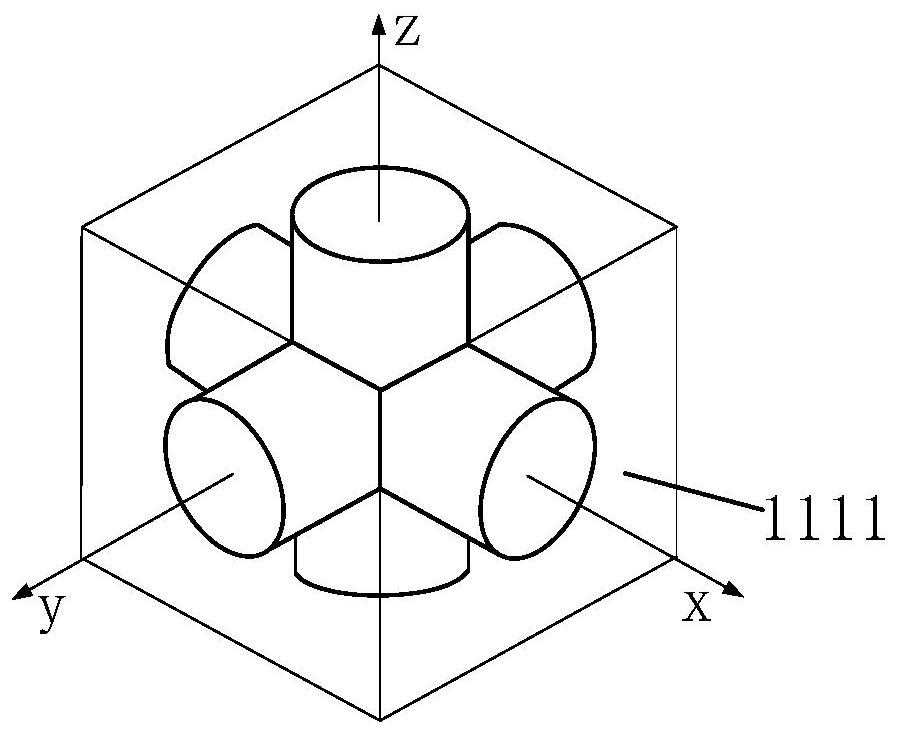

[0040] The design method of the orbital angular momentum vortex electromagnetic wave generating device provided by the present invention, the overall idea is: through the space transformation theory, the discrete rotating phase plate is equivalently transformed into a cylindrical lens, and the size of each basic unit of the microwave lens is changed to realize The change of the relative permittivity of each basic unit changes the propagation path of the incident plane wave in the microwave lens to achieve phase compensation. After being reflected by the metal reflector, the second phase compensation is realized, and the vortex is generated after two phase compensations. electromagnetic waves.

[0041] Taking the design of an orbital angular momentum vortex electromagnetic wave generating device capable of generating vortex electromagnetic waves with a center frequency of 10 GHz and an eigenmode of 1 as an example, the present invention will be described in detail below in conju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com