A method for producing high magnetic induction grain-oriented silicon steel based on ESP endless rolling technology

A technology of high magnetic induction orientation and endless rolling, which is applied in the field of producing high magnetic induction orientation silicon steel based on ESP endless rolling technology, can solve the problems that the research of high magnetic induction orientation silicon steel has not been reported yet, and achieve the omission of nitriding process , reduce roll loss and simplify the heating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

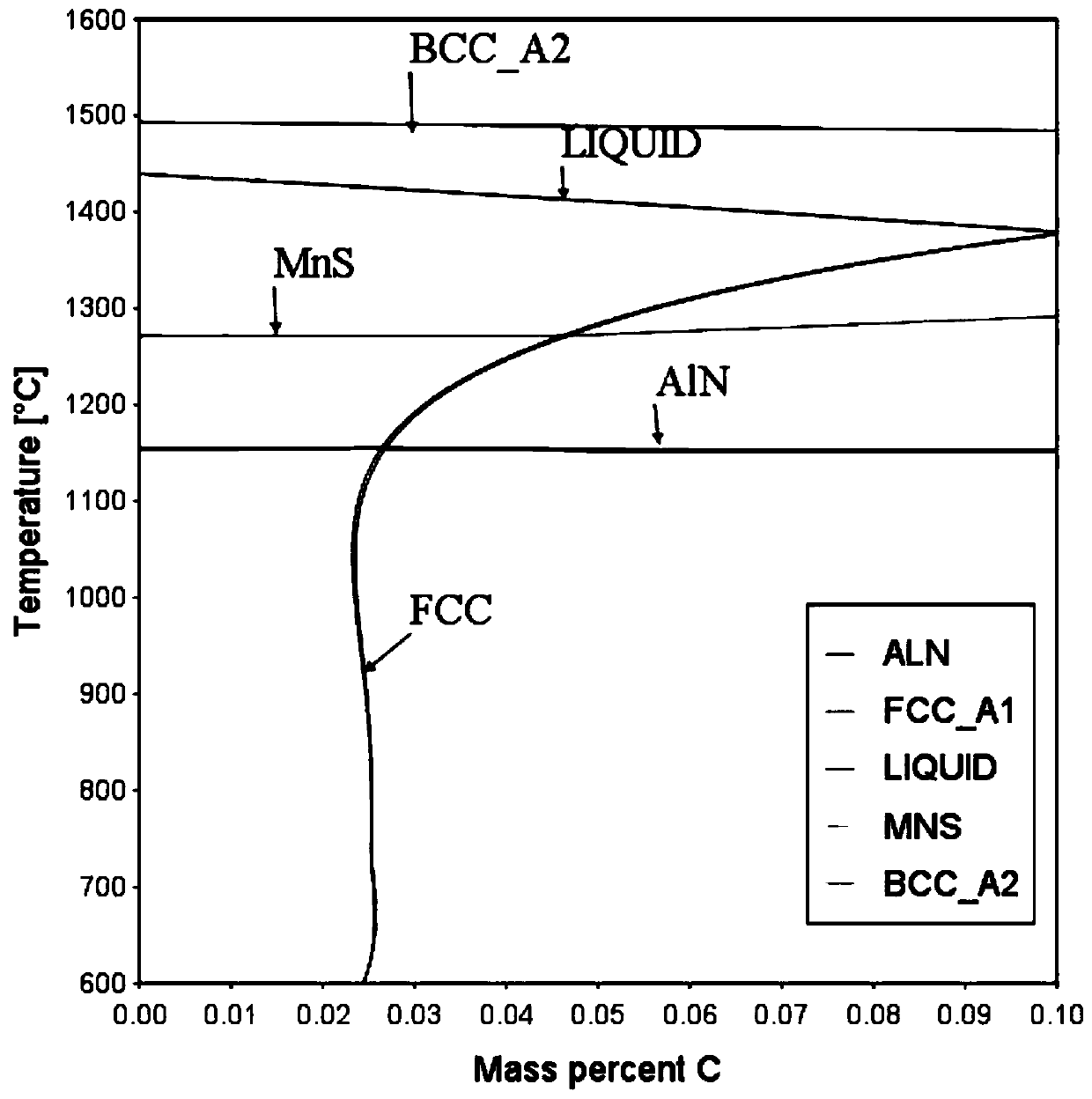

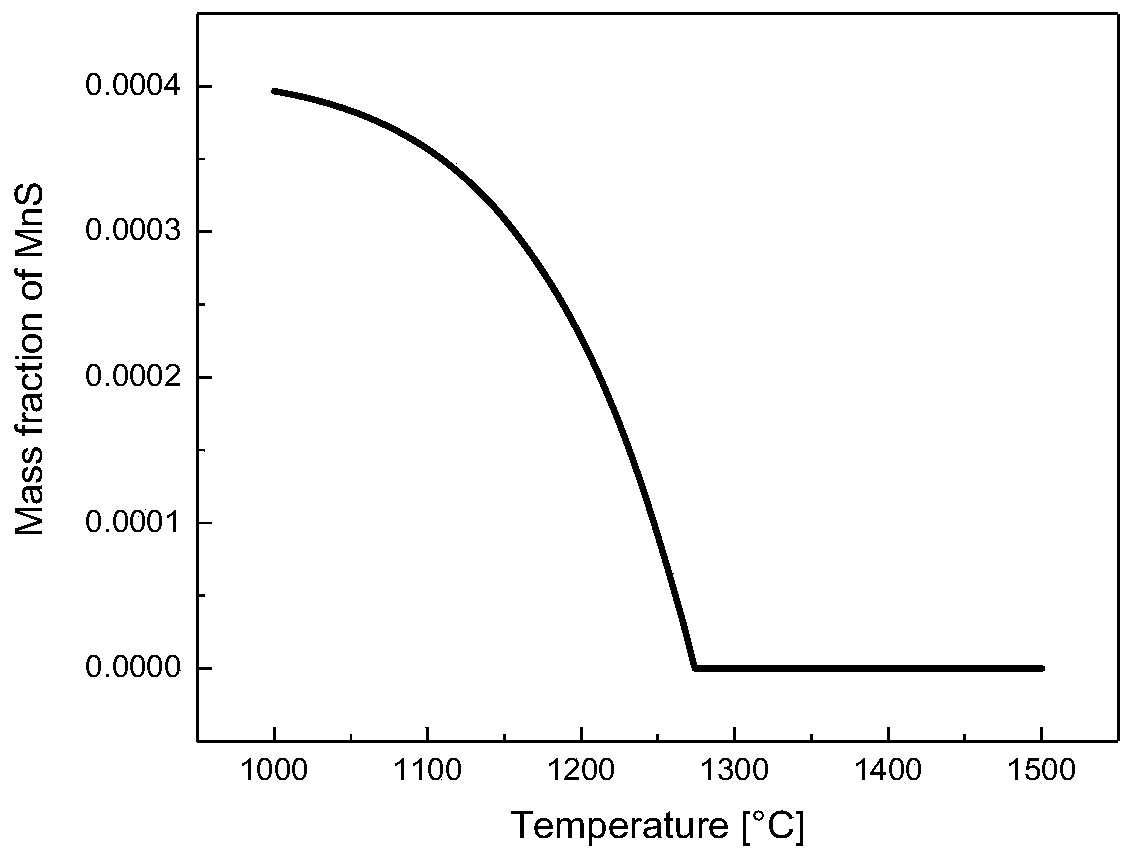

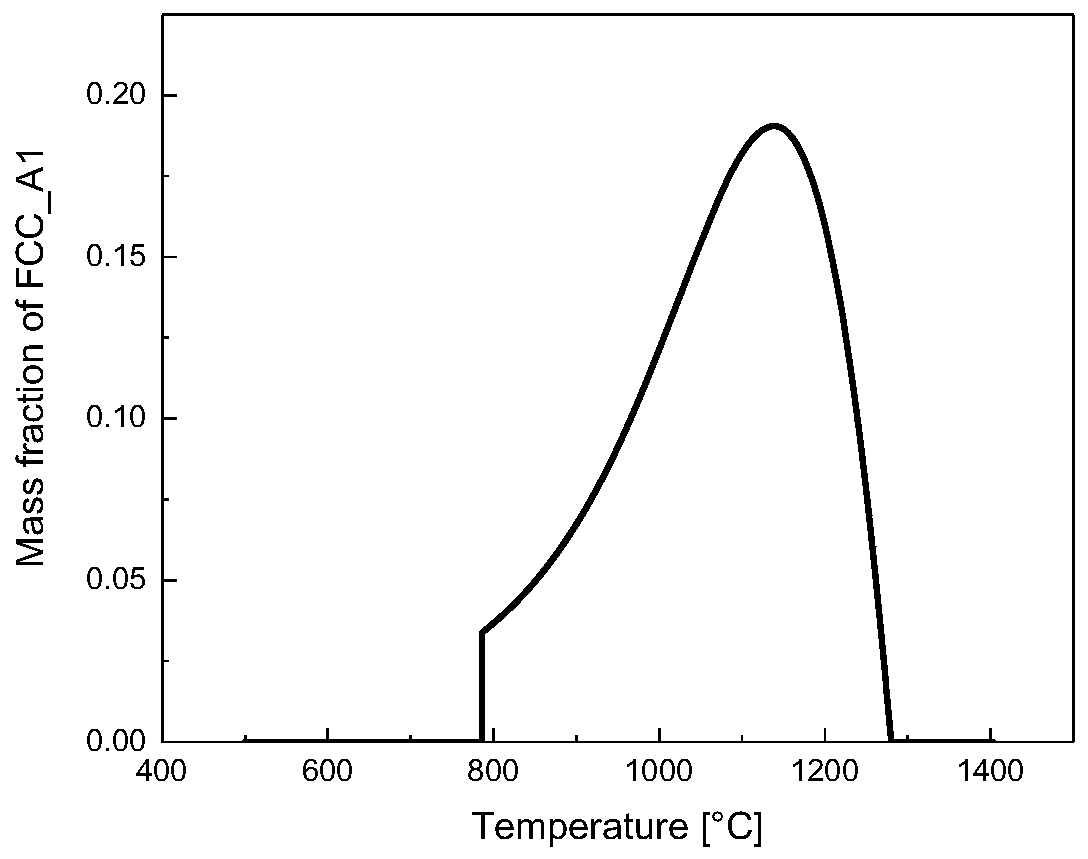

[0060] Composition of grain-oriented silicon steel (by mass percentage) C: 0.06%, Si: 3.1%, Mn: 0.09%, S: 0.015%, Al: 0.03%, N: 0.006%, the rest is iron and inevitable inclusions, orientation The manufacturing process of silicon steel is as follows: After the molten steel is smelted, the thin slab continuous casting machine is used to produce a 90mm cast slab, which is heated to 1380°C by an electromagnetic induction heating furnace, rough rolled to a 20mm intermediate slab, and the temperature at the entrance of the finish rolling unit is 1230°C to be rolled to 2mm. , The final rolling temperature is about 1050°C. Cooling is carried out through the laminar flow cooling section, the laminar flow cooling rate is 60°C / s, and the coiling temperature of the hot-rolled steel strip is 570°C. The hot-rolled sheet is subjected to normalization treatment, the normalization system is 1100°C (20s) + 900 (180s), pickled in 3% HCl for 60s; cold-rolled to 0.18mm, the total deformation is 91...

Embodiment 2

[0062] Oriented silicon steel composition (by mass percentage) C: 0.055%, Si: 3.0%, Mn: 0.08%, S: 0.015%, Al: 0.02%, N: 0.015%, the rest is iron and inevitable inclusions; orientation The manufacturing process of silicon steel is as follows: After the molten steel of the above components is smelted, a thin slab continuous casting machine is used to produce a 100mm thick casting slab, which is heated to 1350°C by an electromagnetic induction heating furnace, rough rolled to a 20mm intermediate slab, and the temperature at the entrance of the finishing rolling unit is 1210°C. Rolled to 2.5mm, the final rolling temperature is about 1000 ℃. The laminar cooling rate is 70°C / s, and the coiling temperature of the hot-rolled steel strip is 550°C. The hot-rolled sheet is subjected to normalization treatment, the normalization system is 1050°C (30s) + 900 (150s), pickled in 3% HCl for 60s; after that, it is cold-rolled to 0.23mm by 7 passes, and the total reduction is 91%. The temperat...

Embodiment 3

[0064] Grain-oriented silicon steel composition (by mass percentage) C: 0.06%, Si: 3.1%, Mn: 0.1%, S: 0.02%, Al: 0.04%, N: 0.015%, the rest is iron and inevitable inclusions, orientation The manufacturing process of silicon steel is as follows: After the molten steel is smelted, the thin slab continuous casting machine is used to produce a 100mm cast slab, which is heated to 1320°C by an electromagnetic induction heating furnace, the temperature at the entrance of the finishing rolling unit is 1180°C, the final rolling temperature is 960°C, and rolled to 2.5 mm, cooling through the laminar cooling section, the laminar cooling rate is 60°C / s, and the coiling temperature of the hot-rolled steel strip is 520°C. The hot-rolled sheet is subjected to normalization treatment, the normalization system is 1100°C (15s) + 900 (180s), pickled in 3% HCl for 60s; after that, it is cold-rolled to 0.3mm by 7 passes, the total deformation is 88%, and the sheet temperature The temperature is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com