High-strength flexible anti-interference buggy ladle cable and preparation method thereof

A ladle car, high-strength technology, applied in the direction of cable/conductor manufacturing, power cables, insulated cables, etc., can solve the problems of sheath cracking, wire core breakage, etc., and achieve the effect of increasing tensile performance, easy to move, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

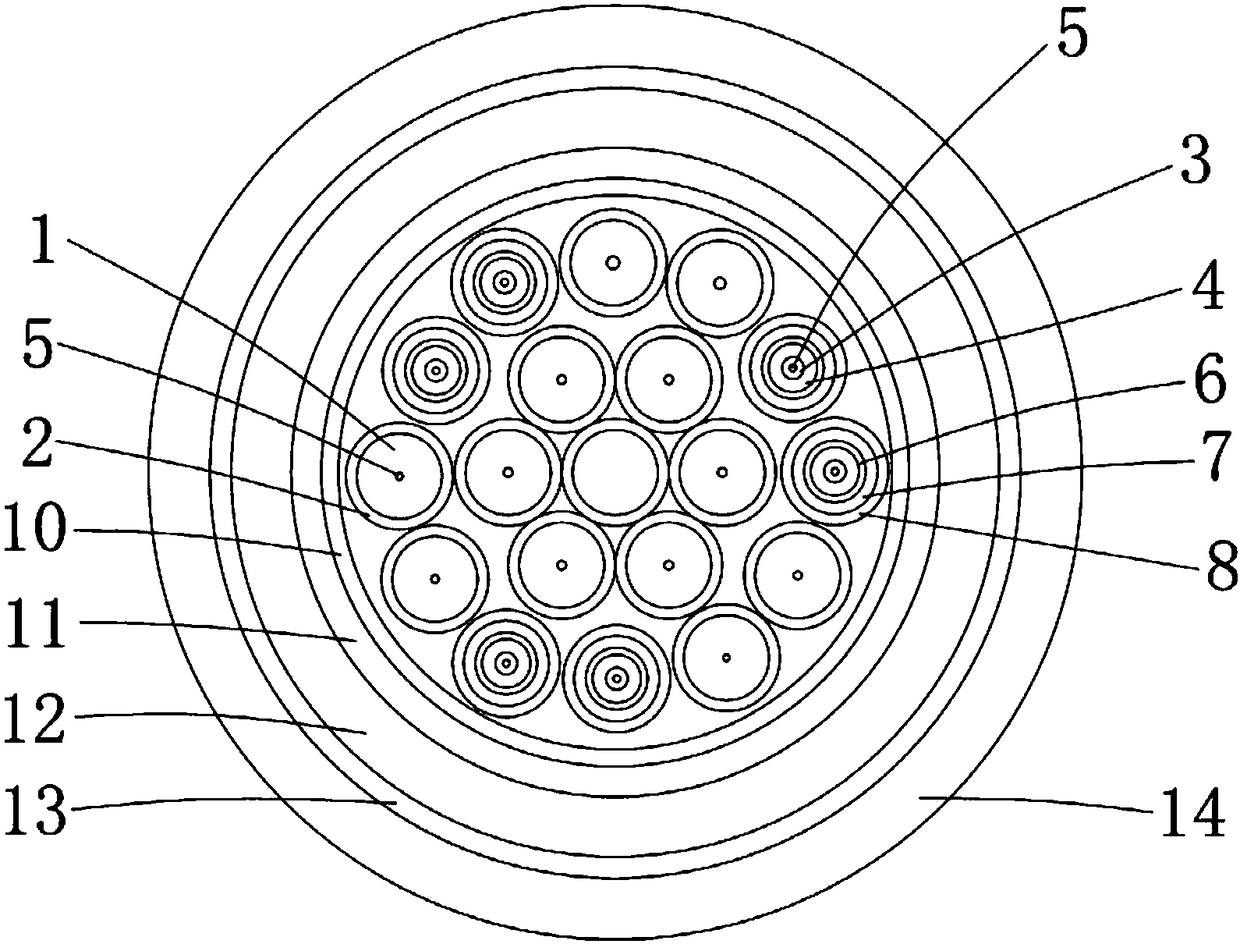

[0034] The preparation method of the high-strength soft anti-interference ladle car cable of the present invention comprises the following steps:

[0035] Step 1, prepare the power core:

[0036] The tinned copper wire is drawn-annealed-tinned-twisted to form a power conductor, and the aramid wire 5 is placed in the center and twisted together with the tinned copper wire, and the twisting pitch is controlled at 10 to 12 times the outer diameter of the power conductor;

[0037] Extrude the insulation layer of the power conductor with polyvinyl chloride insulating material outside the power conductor, and finish it on the extruder by extrusion;

[0038] Step 2, prepare the signal wire core, the method is the same as step 1;

[0039] Step 3, use insulating polyester tape to overlap and wrap the outside of the signal wire core to form a signal wire core tape layer, and the covering rate is controlled between 15% and 20%;

[0040] φ0.12mm tinned annealed copper wire is braided ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com