Copper-zinc alloy current collector for inhibiting lithium dendrites

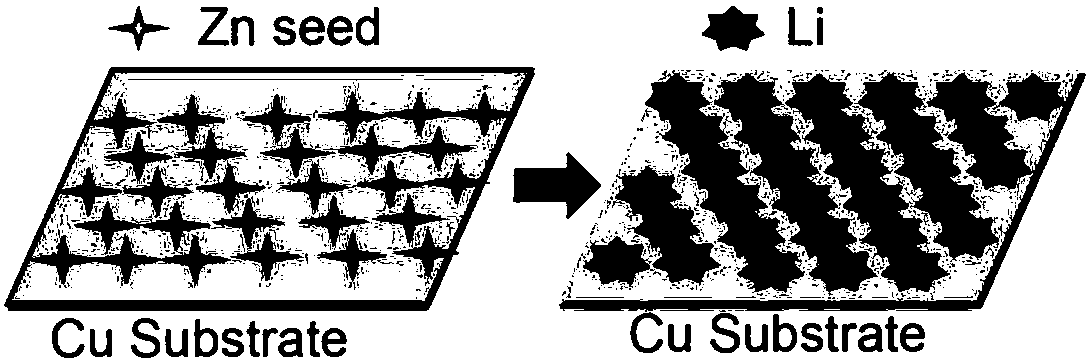

A current collector and lithium dendrite technology, applied in the field of high-energy storage metal lithium batteries, can solve the problems of lithium dendrite growth, unevenness, and uneven enrichment of metal lithium, and achieve long-cycle, easy-to-promote, lithium-ion evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

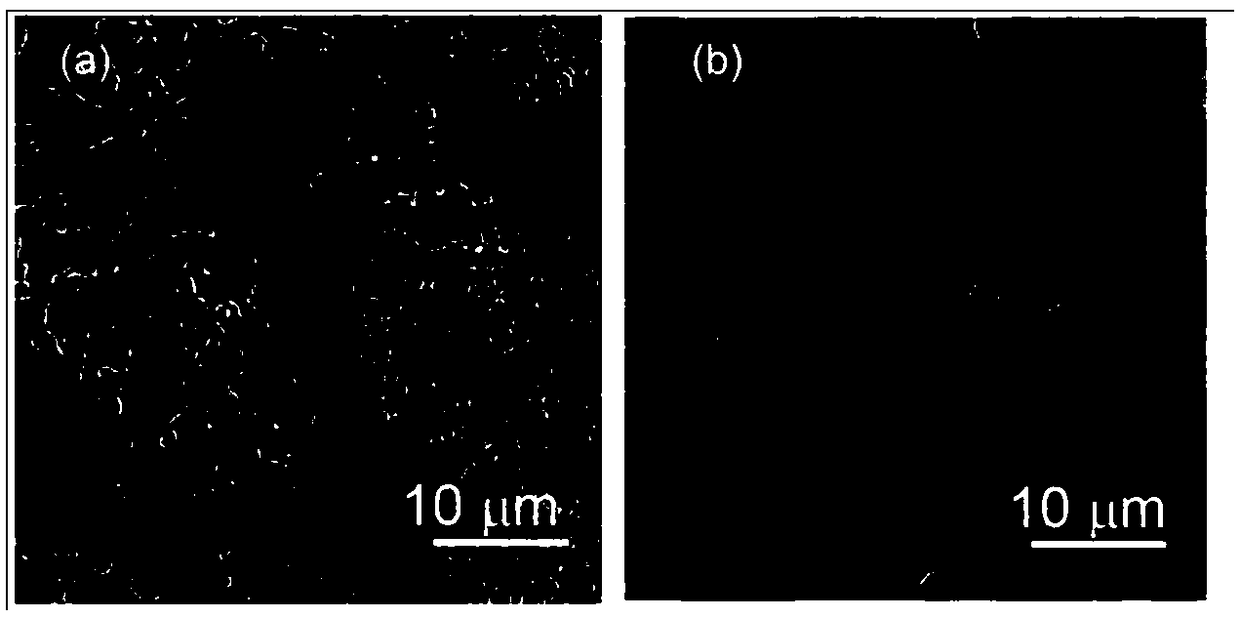

[0022] In this example, the copper-zinc alloy current collector is prepared by magnetron sputtering, customized sputtering / electron beam / ICP-CVD (base pressure<1E-6 Torr, ICP-CVD chamber). Typical deposition conditions: the plasma gas flow rate is 100sccm, the plasma power is 200W, the substrate is copper foil, the zinc content in the CuZn alloy target is 1%, and finally 10nm copper-zinc alloy is deposited on the ordinary copper foil.

example 2

[0024] In this example, the copper-zinc alloy current collector is prepared by magnetron sputtering, the substrate is nickel foil, the zinc content in the CuZn alloy target is 3%, and 200nm copper-zinc alloy is deposited on the common copper foil. Other conditions are the same as Example 1.

example 3

[0026] In this example, the copper-zinc alloy current collector is prepared by magnetron sputtering method, the substrate is titanium foil, the zinc content in the CuZn alloy target is 5%, and 1000nm copper-zinc alloy is deposited on the common copper foil. Other conditions are the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com