Electrodynamic integrated farmland in-situ remediation device and remediation method thereof

An in-situ remediation and electric technology, applied in the field of contaminated soil remediation, can solve problems such as inability to reach farmland, achieve high efficiency of deep plowing and remediation, high energy conversion efficiency, and increase the depth of plowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

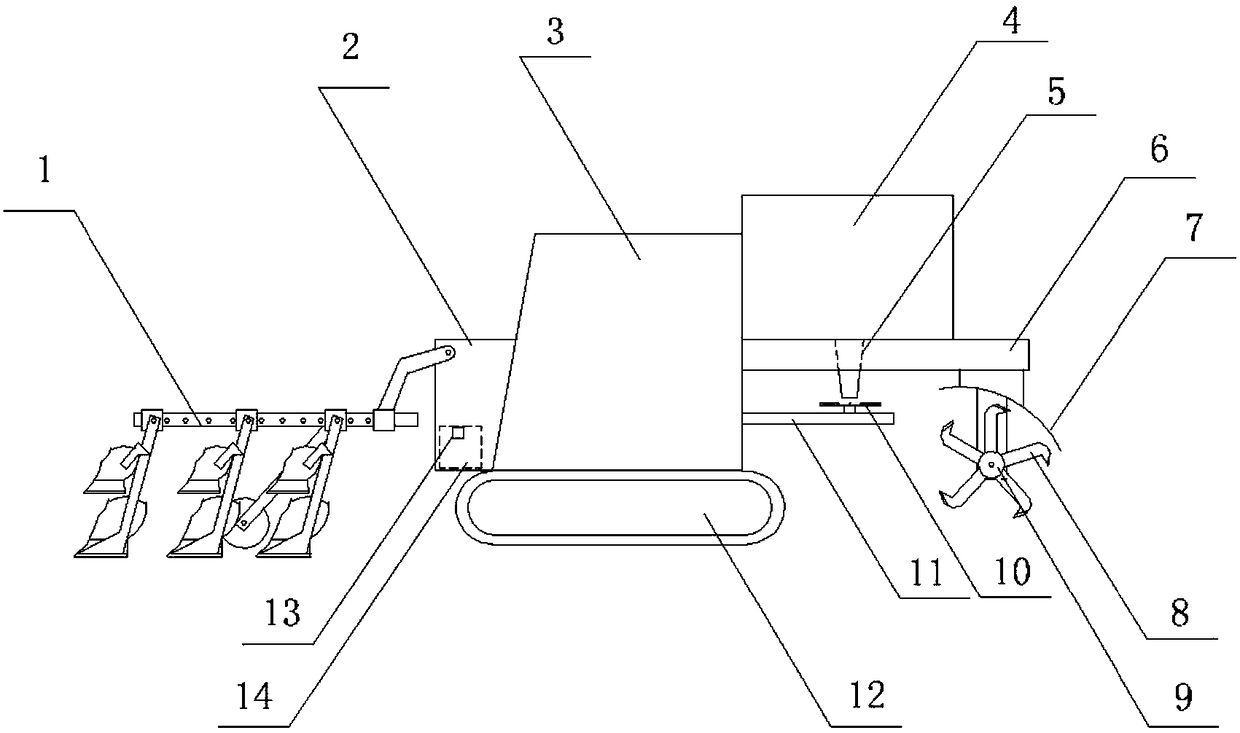

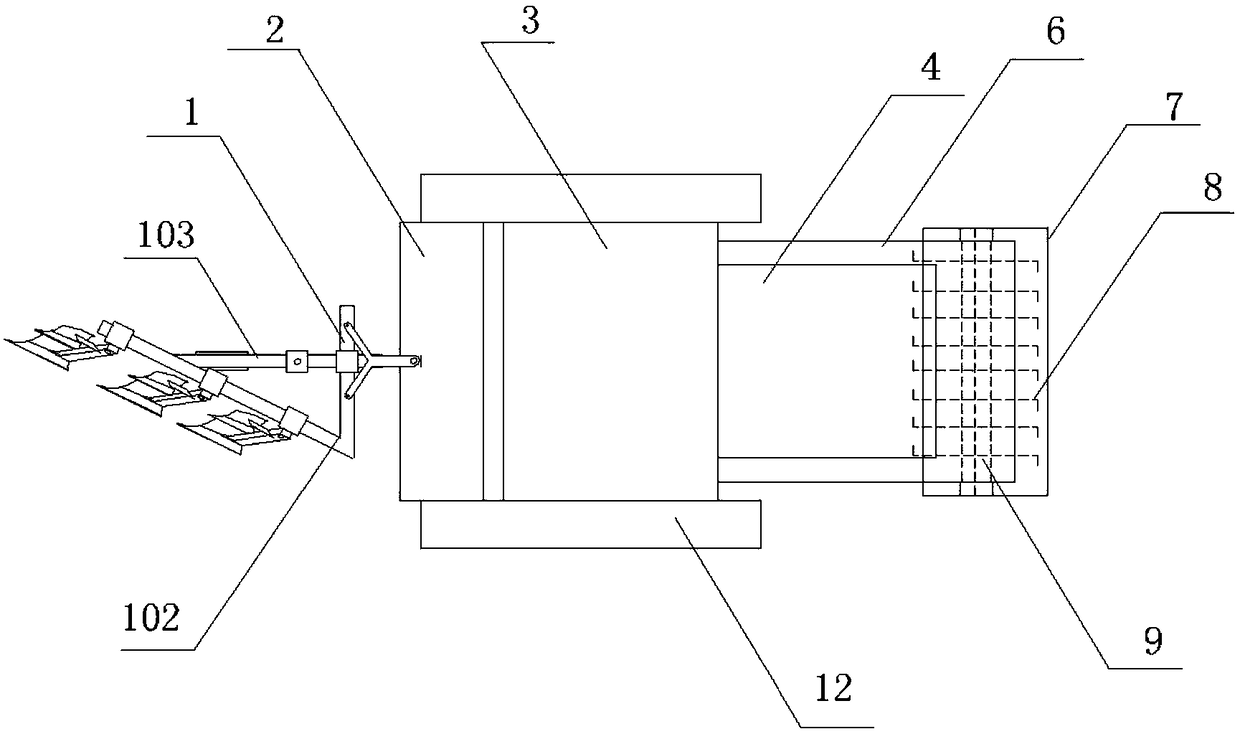

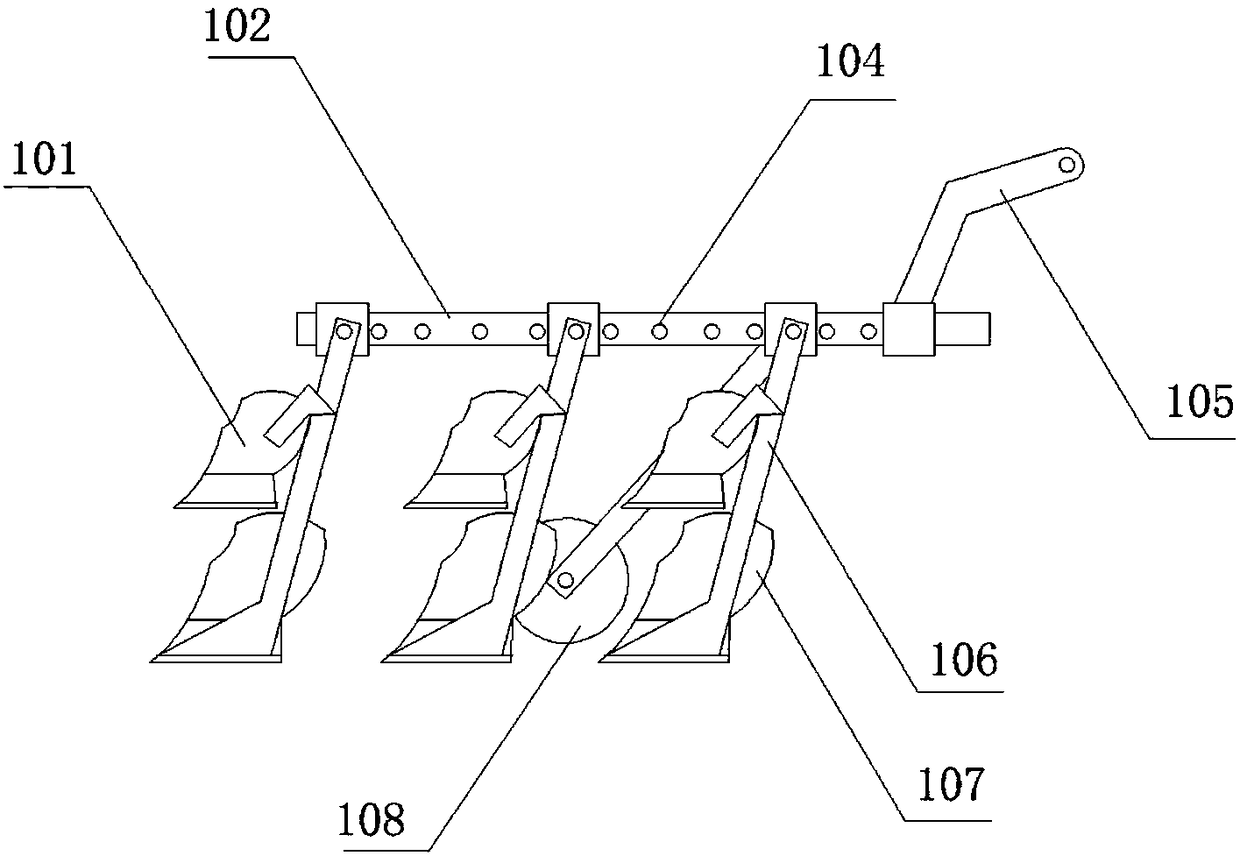

Embodiment example 1

[0039] A farmland was polluted by heavy metals. The main pollutants in the soil were arsenic, cadmium, lead, and zinc. was 21%. The soil is repaired using the equipment and method described in the present invention. The angle between the plow column and the ground is set to be 75°, the number of the plow column is 3, and the length of the plow column is 75 cm. The restoration equipment runs in a clockwise direction from a position close to the border of the farmland to carry out in-situ deep plowing on the polluted soil. The deep plowing depth is 60cm. Stir the mixer to mix the passivator and the polluted soil evenly, and apply the passivator at a rate of 40kg / min; then sprinkle water on the soil that has been mixed with the passivator so that the moisture content of the polluted soil is 23%. Corn was planted 9 days after passivation repair. After one season of planting, the available content of arsenic, cadmium, lead, and zinc in the soil and the yield of the crops were mea...

Embodiment example 2

[0043] A farmland was polluted by heavy metals. The main pollutants in the soil were arsenic, cadmium, copper, and zinc. 18%. The soil is repaired using the equipment and method described in the present invention. The angle between the plow column and the ground is set to be 90°, the number of the plow column is 4, and the length of the plow column is 60 cm. The restoration equipment runs in a clockwise direction from a position close to the border of the farmland to carry out in-situ deep plowing on the polluted soil with a deep plowing depth of 50cm. Stir the mixer to mix the passivator with the polluted soil evenly, and apply the passivator at a rate of 80kg / min; then sprinkle water on the soil that has been mixed with the passivator so that the moisture content of the polluted soil is 23%. Corn was planted 9 days after passivation repair. After one season of planting, the available content of arsenic, cadmium, lead, and zinc in the soil and the yield of the crops were me...

Embodiment example 3

[0047] A farmland was polluted by heavy metals. The main pollutants in the soil were arsenic, cadmium, copper, and zinc. 18%. The soil is repaired using the equipment and method described in the present invention. The angle between the plow column and the ground is set to be 85°, the number of the plow column is 2, and the length of the plow column is 35 cm. The restoration equipment runs in a clockwise direction from a position close to the border of the farmland to carry out in-situ deep plowing on the polluted soil with a deep plowing depth of 20cm. Stir the mixer to mix the passivator and the polluted soil evenly, and apply the passivator at a rate of 10kg / min; then sprinkle water on the soil that has been mixed with the passivator so that the moisture content of the polluted soil is 23%. Rapeseed was planted 9 days after passivation repair. After one season of planting, the available content of arsenic, cadmium, lead, and zinc in the soil and the yield of the crops were...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com