Method for processing perfume wastewater through Fenton combination process

A combined process and waste water technology, applied in filtration treatment, water/sewage treatment, natural water treatment, etc., can solve the problems of high operating cost and low treatment efficiency, and achieve faster oxidation rate, lower CODcr and chroma, and lower difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of method that Fenton's combination process handles perfume waste water, comprises the following steps:

[0026] ①Put the spice wastewater in the waste water pool through the grid to remove large particles, add polymer flocculant while stirring, the addition amount is 1mg / L, continue to stir for 5 minutes after adding, and place it for 5 hours. During the place, keep the temperature of the waste water at 30°C, filter, remove flocs, and use fragrance wastewater for later use;

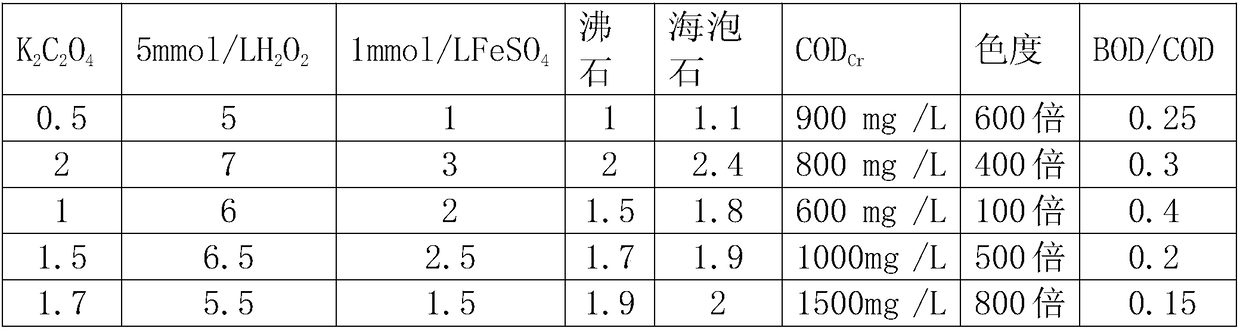

[0027] ② Place the pretreated spice wastewater in step ① in an iron-carbon aerated micro-electrolysis reactor with a gas-water ratio of 2:1, react for 1 hour, then transfer the treated spice wastewater into a glass container, and then put it into K 2 C 2 o 4 , 5mmol / LH 2 o 2 , 1mmol / LFeSO 4 , zeolite, sepiolite, stirred for 20min; the pH value was adjusted to 3 and placed in the magnetic field of the electromagnetic machine for 25min, while the irradiation of a 20w ultraviolet lamp was...

Embodiment 2

[0032] A kind of method that Fenton's combination process handles perfume waste water, comprises the following steps:

[0033] ①Put the spice wastewater in the wastewater pool through the grid to remove large particles, add polymer flocculant while stirring, the addition amount is 1.3mg / L, continue to stir for 10min after adding, and place it for 10h. During the period, keep the temperature of the wastewater at 35°C, filter to remove flocs, and use spice wastewater for later use;

[0034] ② Place the pretreated spice wastewater in step ① in an iron-carbon aerated micro-electrolysis reactor with a gas-water ratio of 2:1, react for 1 hour, then transfer the treated spice wastewater into a glass container, and then put it into K 2 C 2 o 4 , 5mmol / LH 2 o 2 , 1mmol / LFeSO 4 , zeolite, sepiolite, stirred for 20min; the pH value was adjusted to 3 and placed in the magnetic field of the electromagnetic machine for 50min, and the irradiation of the ultraviolet lamp of 100w was adop...

Embodiment 3

[0039] A kind of method that Fenton's combination process handles perfume waste water, comprises the following steps:

[0040] ①Put the spice wastewater in the waste water tank through the grid to remove large particles, add polymer flocculant while stirring, the amount of addition is 1.2mg / L, continue to stir for 6 minutes after adding, and place it for 7 hours. During the place, keep the temperature of the waste water at 33°C, filter to remove flocs, and use spice wastewater for later use;

[0041] ② Place the pretreated spice wastewater in step ① in an iron-carbon aerated micro-electrolysis reactor with a gas-water ratio of 2:1, react for 1 hour, then transfer the treated spice wastewater into a glass container, and then put it into K 2 C 2 o 4 , 5mmol / LH 2 o 2 , 1mmol / LFeSO 4 , zeolite, sepiolite, stirred for 20min; the pH value was adjusted to 3 and placed in the magnetic field of the electromagnetic machine for 35min, and the irradiation of the ultraviolet lamp of 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com