Sintering water permeable brick produced by using crushed stone material and preparation method thereof

A technology of permeable bricks and crushed materials, which is applied in the field of sintered permeable bricks and its preparation, which can solve the problems of multiple production processes, bulky ball mill equipment, and low ultimate load, and achieve shortened production time, excellent water permeability, and strong frost resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0068] As a preferred embodiment of the present invention, the main raw materials of the primer in parts by mass are as follows:

[0069] Stone scraps 90-96 parts

[0070] Adhesive base 5-8 parts

[0071] Liquid glue 5-8 parts;

[0072] The bonding base material is one or more of bentonite and clay;

[0073] The liquid gel is one or more of silica sol solution, polyacrylamide solution, and guar gum solution.

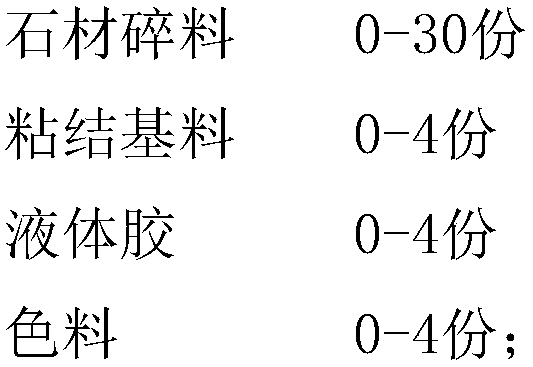

[0074] The main raw materials of the fabric in parts by mass are as follows:

[0075]

[0076] The bonding base material is one or more of bentonite and clay;

[0077] The liquid gel is one or more of silica sol solution, polyacrylamide solution, and guar gum solution.

[0078] As a better embodiment of the present invention, the binder is also added to the frit, that is,

[0079] The main raw materials of the base material in parts by mass are as follows:

[0080]

[0081] The bonding base material is one or more of bentonite and clay;

[0082] The liquid ...

Embodiment 1

[0121] (1) Formula: including lining and base material, wherein, the main raw material of described base material is as follows in parts by mass:

[0122]

[0123] The bonding base material is bentonite, and the liquid glue is a silica sol solution;

[0124] The main raw materials of the fabric in parts by mass are as follows:

[0125]

[0126] The bonding base material is bentonite, and the liquid glue is a silica sol solution;

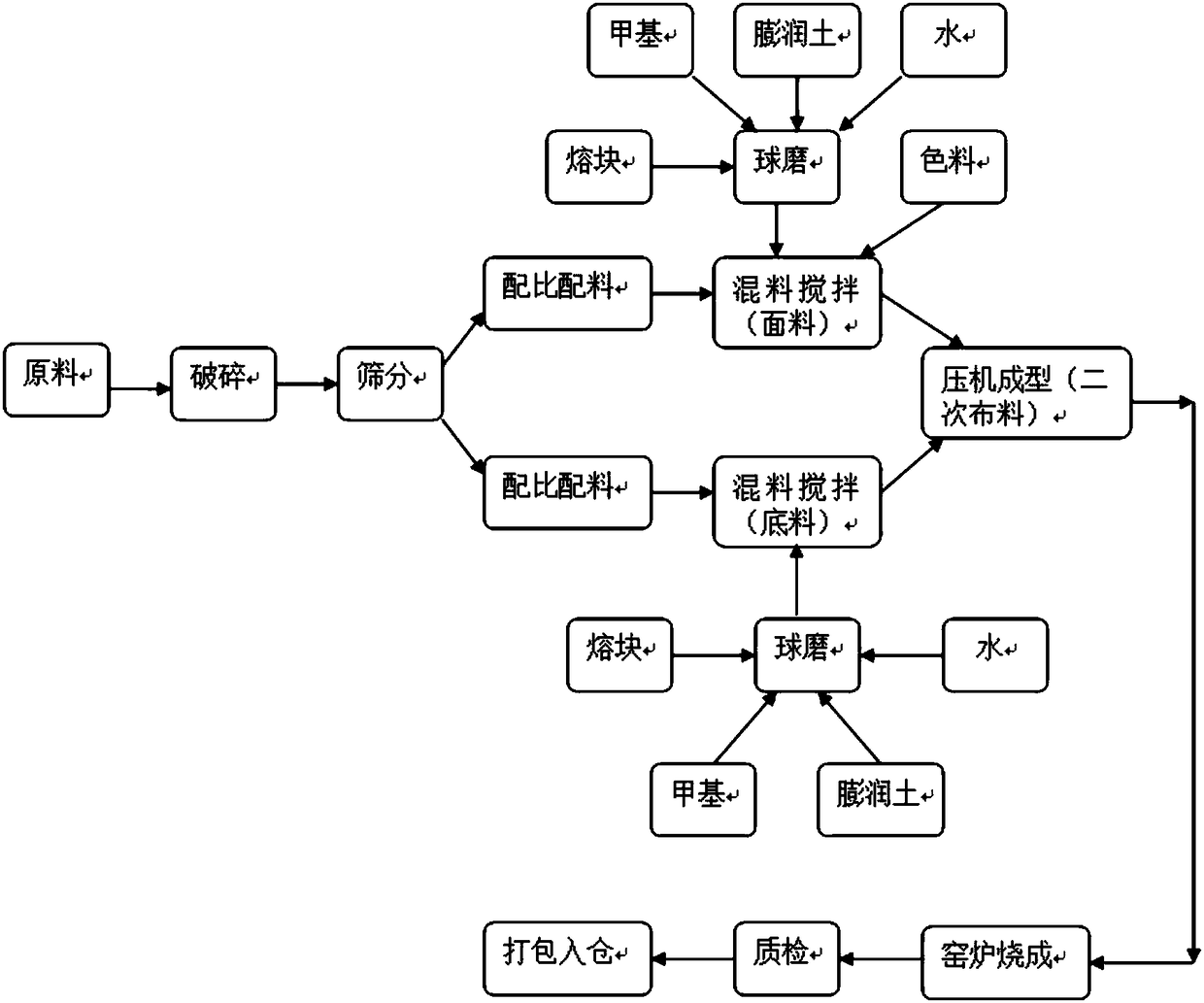

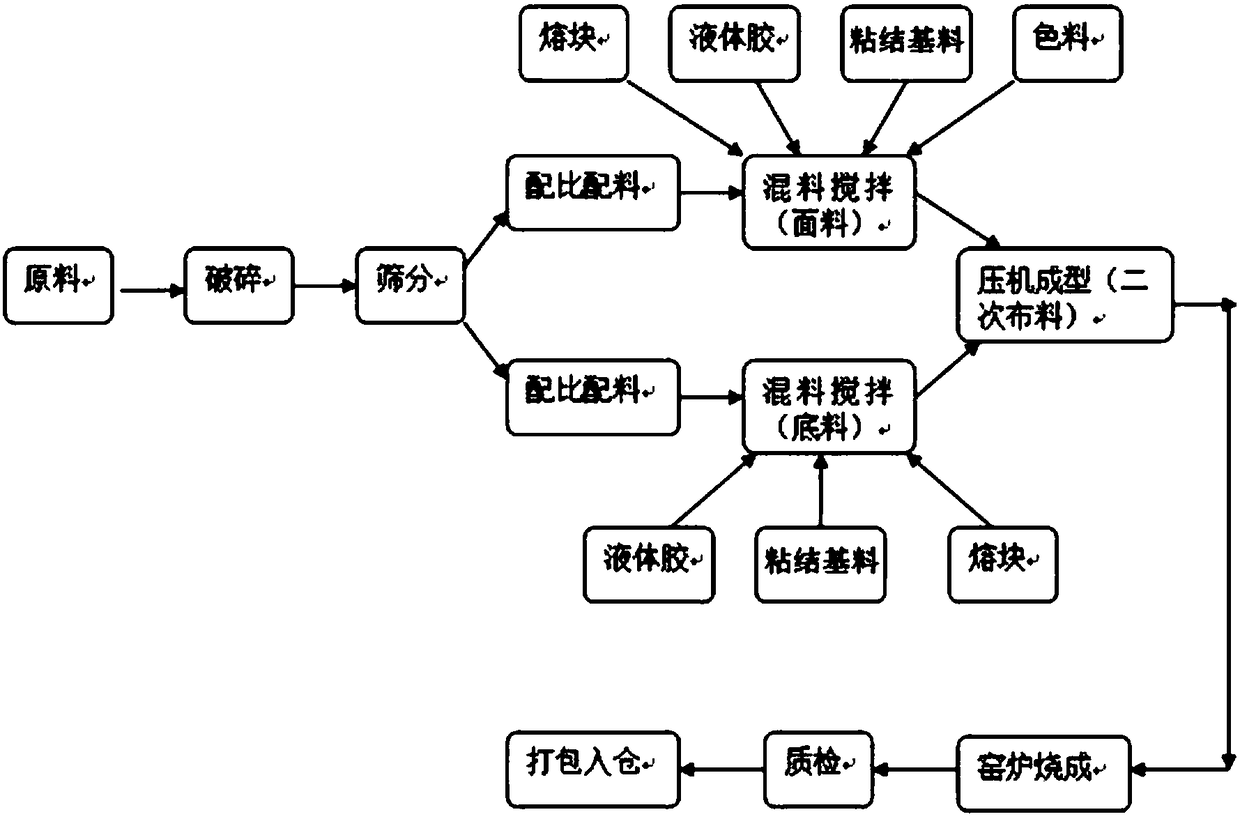

[0127] (2) Preparation method

[0128] (1) Crushing stone fragments;

[0129] (2) Sieve the crushed stone fragments to sieve out particles with different particle size ranges;

[0130] (3) Mix the crushed stone particles after sieving according to the base material formula, add bonding base material and liquid glue, and stir evenly to obtain the base material; mix the crushed stone particles after sieving according to the formula of the fabric Perform batching, add bonding base material, liquid glue and colorant, and stir evenly to obtain fab...

Embodiment 2

[0134] (1) Formula: including lining and base material, wherein, the main raw material of described base material is as follows in parts by mass:

[0135]

[0136] The bonding base material is kaolin, and the liquid glue is sodium polyacrylate;

[0137] The main raw materials of the fabric in parts by mass are as follows:

[0138]

[0139] The bonding base material is black mud, and the liquid glue is polyvinylpyridinium salt;

[0140] (2) Preparation method

[0141] (1) Crushing stone fragments;

[0142] (2) Sieve the crushed stone fragments to sieve out particles with different particle size ranges;

[0143] (3) Mix the crushed stone particles after sieving according to the base material formula, add bonding base material and liquid glue, and stir evenly to obtain the base material; mix the crushed stone particles after sieving according to the formula of the fabric Perform batching, add bonding base material, liquid glue and colorant, and stir evenly to obtain fab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com