Novel process for preparing carbon-based slow-release composite fertilizer from waste biomass

A technology of waste biomass and slow-release compound fertilizer, which can be used in calcium fertilizers, fertilization devices, inorganic fertilizers, etc., and can solve problems such as dealing with environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

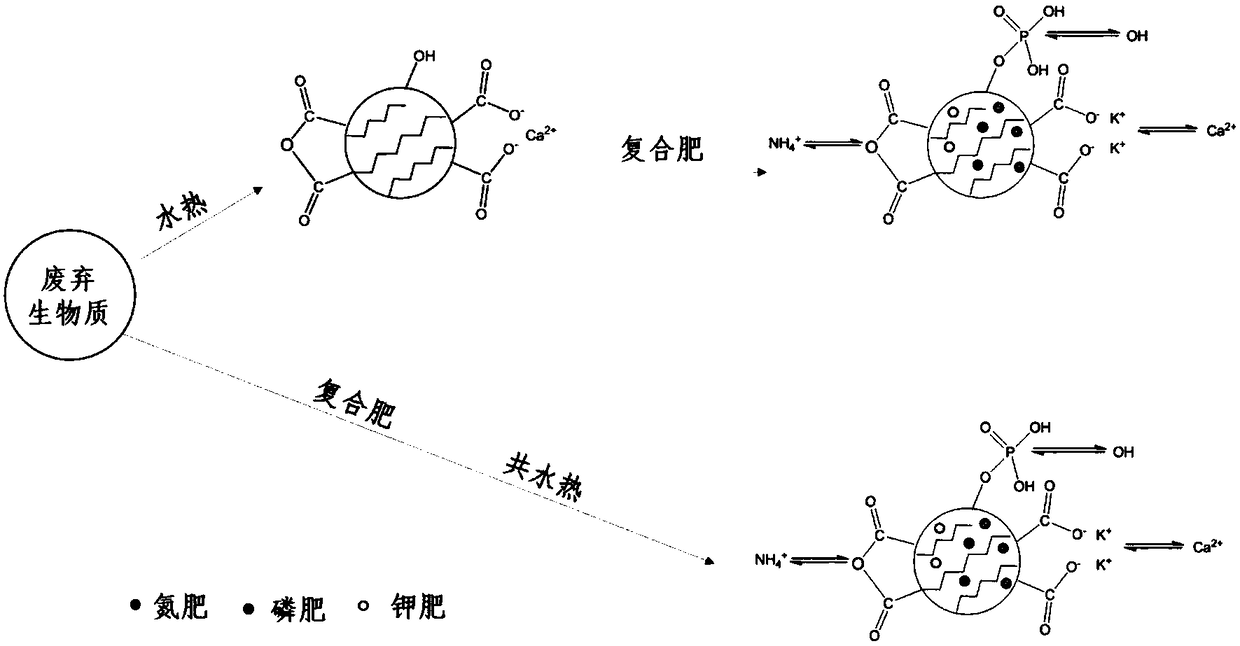

Method used

Image

Examples

Embodiment 1

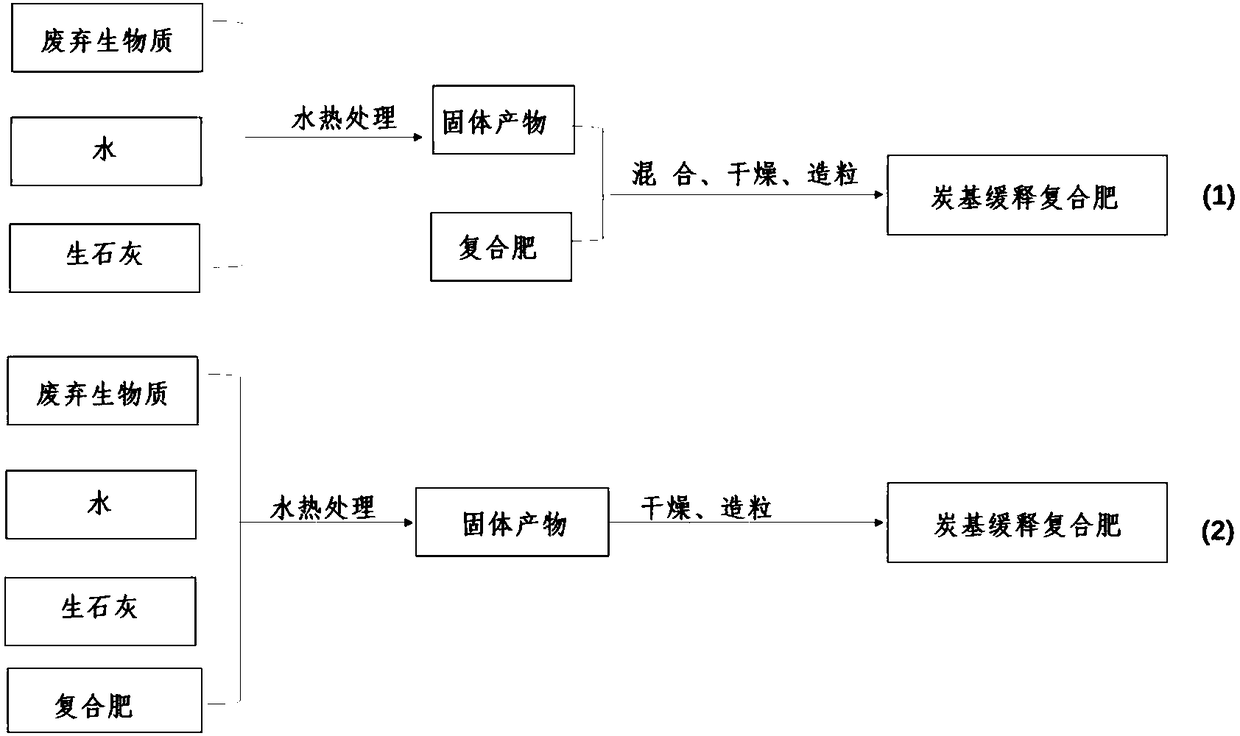

[0023] 1. Preparation of carbon-based compound fertilizer

[0024] The waste biomass was pig manure and corn stalks. The waste biomass was dried and crushed to less than 5mm, and set aside. Commercial compound fertilizer N:P:K=18:15:15; the basic properties of the test soil are as follows: TOC 11.76g / kg; TN 0.68g / kg; TP 0.39 g / kg; TK 17.63g / kg, pH 7.23.

[0025] 1) Mix biomass (dry basis) and water at a ratio of 1:5, and biomass (dry basis) and quicklime at a ratio of 1:5, and then put them into a hydrothermal reactor.

[0026] 2) Heating the reactor to 210°C and maintaining it for 60 minutes; then cooling by an electric fan and internal circulating cooling water, and then performing solid-liquid separation to obtain a solid product;

[0027] 3) The solid product and the compound fertilizer are mixed according to the ratio of 1:4 (the drying ratio is 0.65:4), mechanically stirred for 30 minutes, and then granulated with a disc granulator to 3-4mm and dried to obtain the carb...

Embodiment 2

[0035] Pig manure and wheat straw were used as waste biomass in the preparation of carbon-based slow-release compound fertilizer. Fully mix waste biomass, quicklime, water, and compound fertilizer according to the following proportions (the weight ratio of waste biomass dry basis weight to water is 1:10, the weight ratio of biomass dry basis weight to compound fertilizer is 1:5, waste The weight ratio of biomass dry basis weight and lime is 1:5), and carry out total hydrothermal treatment, hydrothermal treatment condition is identical with embodiment 1;

[0036] In the determination of slow-release compound fertilizer fertilizer efficiency, the application amount of slow-release compound fertilizer was changed to 320kg / hm 2 , the amount of compound fertilizer used in the comparison test was changed to 285kg / hm 2 Except, others are all identical with embodiment 1.

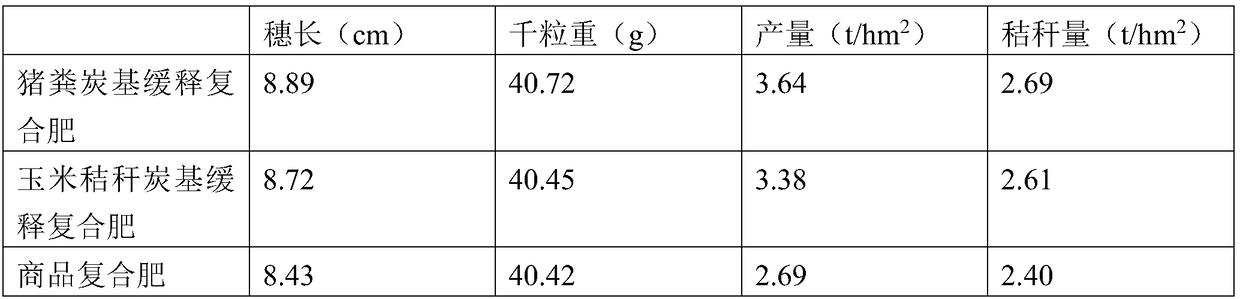

[0037] The effects of carbon-based slow-release compound fertilizers on wheat are shown in Table 2.

[0038] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com