Method and system for preparing oceanic waterproof and oil-proof ceramic coating on substrate surface

A waterproof and oil-proof, ceramic coating technology, applied in the coating field, can solve the problems of affecting the normal operation of work, not having sterilization and mildew resistance, and high difficulty in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

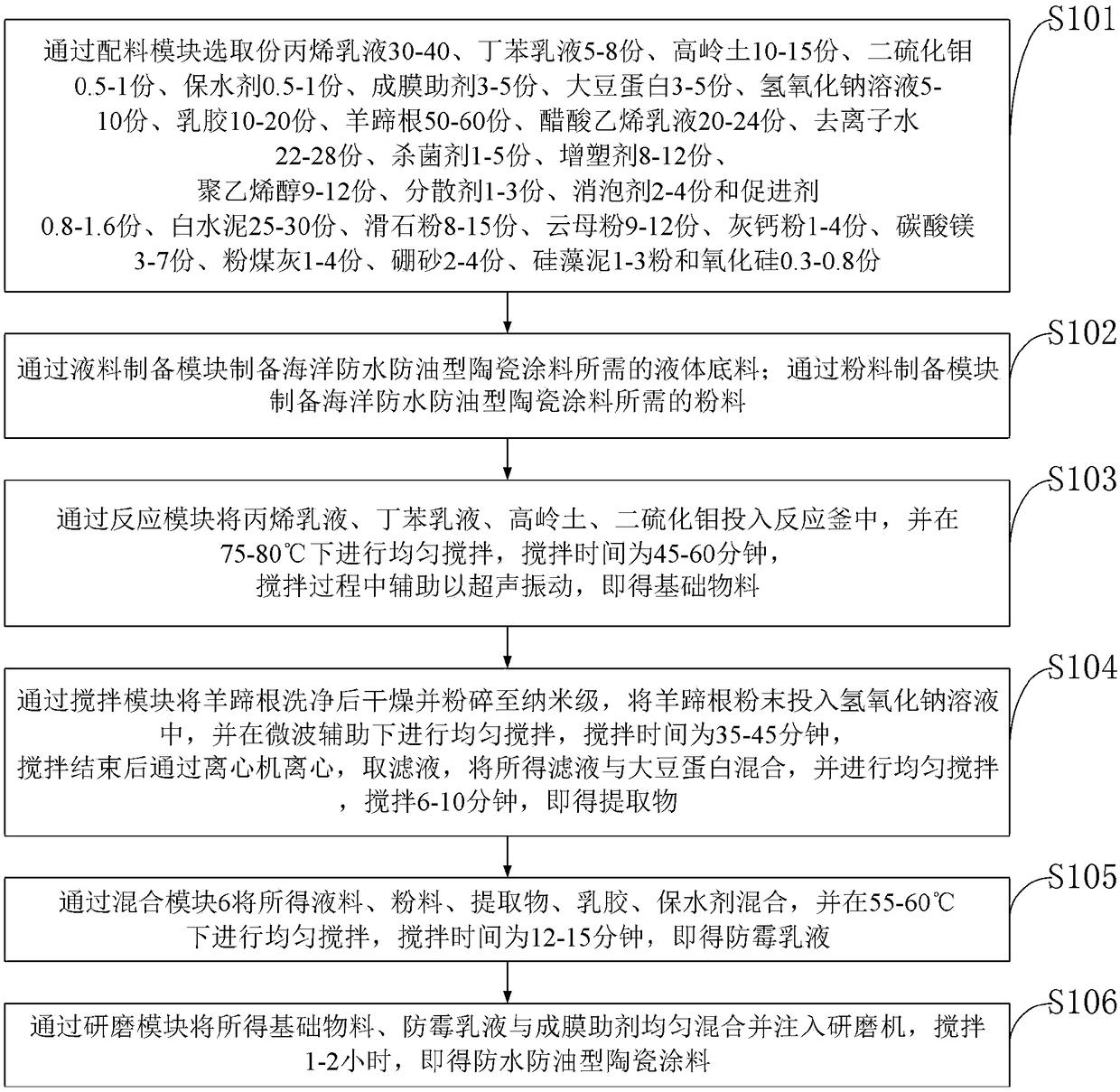

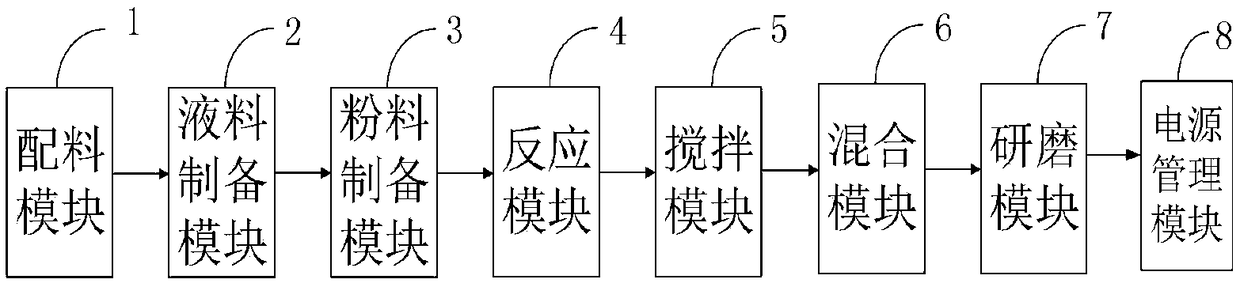

[0091] Such as figure 1 As shown, a kind of method provided by the invention prepares marine waterproof and oil-repellent type ceramic paint on the substrate surface comprises the following steps:

[0092]S101, select 30-40 parts of propylene emulsion, 5-8 parts of styrene-butadiene emulsion, 10-15 parts of kaolin, 0.5-1 part of molybdenum disulfide, 0.5-1 part of water-retaining agent, and 3-5 parts of film-forming aid through the batching module , 3-5 parts of soybean protein, 5-10 parts of sodium hydroxide solution, 10-20 parts of latex, 50-60 parts of sheep's trotter root, 20-24 parts of vinyl acetate emulsion, 22-28 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com