Horizontal domestic garbage combustion furnace

A technology for domestic waste incineration and incinerator, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of low temperature rise, random simplification of operations, large expenditures, etc., and achieves small equipment investment, complete incineration, and reduced The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below according to accompanying drawing and specific embodiment:

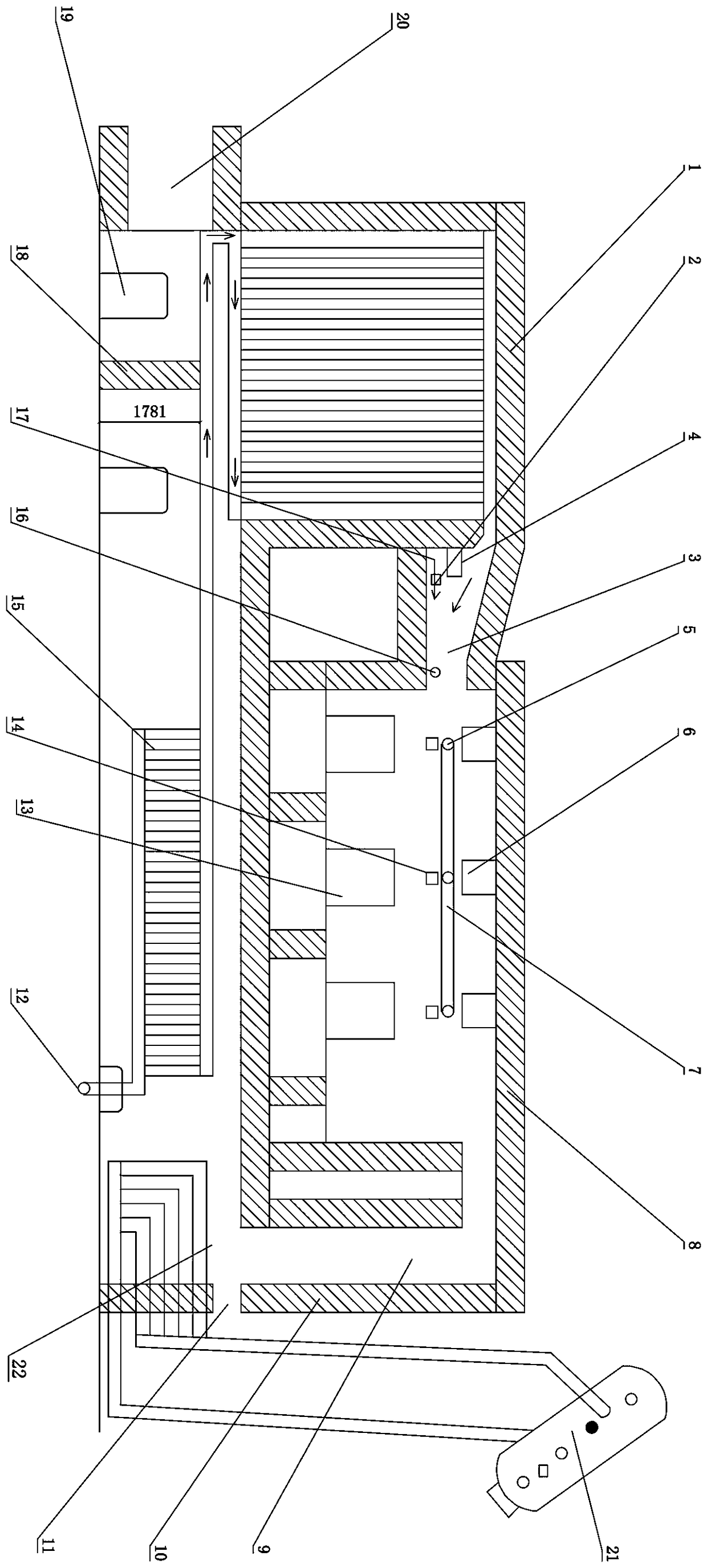

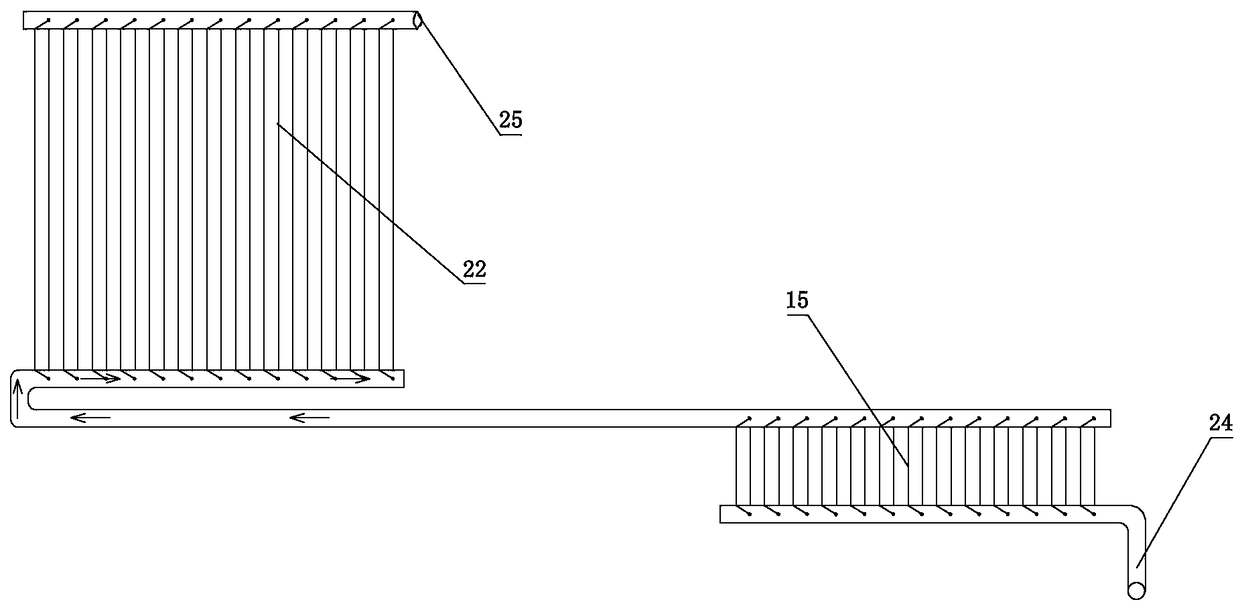

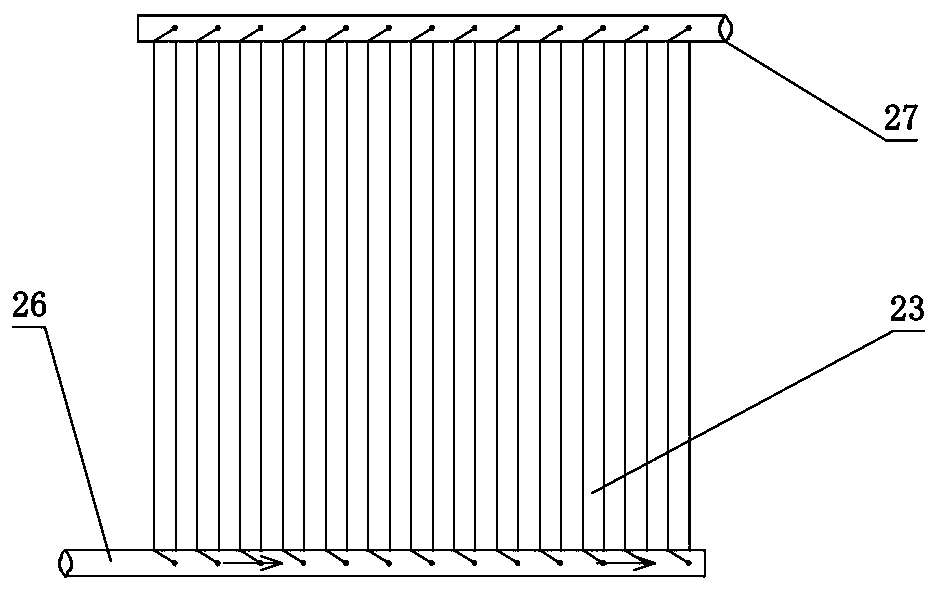

[0024] from figure 1 It can be seen that the present invention is a horizontal domestic waste incinerator, including an incinerator body and a heat exchange system, and the heat exchange system includes a primary air heat exchanger, a secondary air heat exchanger, a hot water heater and a gas heating system. The top of the main body of the incinerator is arched. There are multiple feeding ports on the top of the main body of the incinerator. There are heating air pipes below the feeding ports. There are multiple heating air pipe inlets on the heating air pipes. A block breaking device is installed at the lower part of the tube corresponding to the feeding port to break up the burnt coke. There is an ash collection chamber at the bottom of the main body of the incinerator, and a lower ash hopper is provided above the ash collection chamber. There is a venti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com