Method and device for fast measurement of keyboard keycap flatness based on structured light imaging

A technology of structured light imaging and measurement methods, applied in measurement devices, optical devices, instruments, etc., can solve the problems of high equipment cost and maintenance cost, low detection accuracy, slow detection speed, etc., to solve the problems of physical installation and mobile The effect of error, high detection accuracy and convenient switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

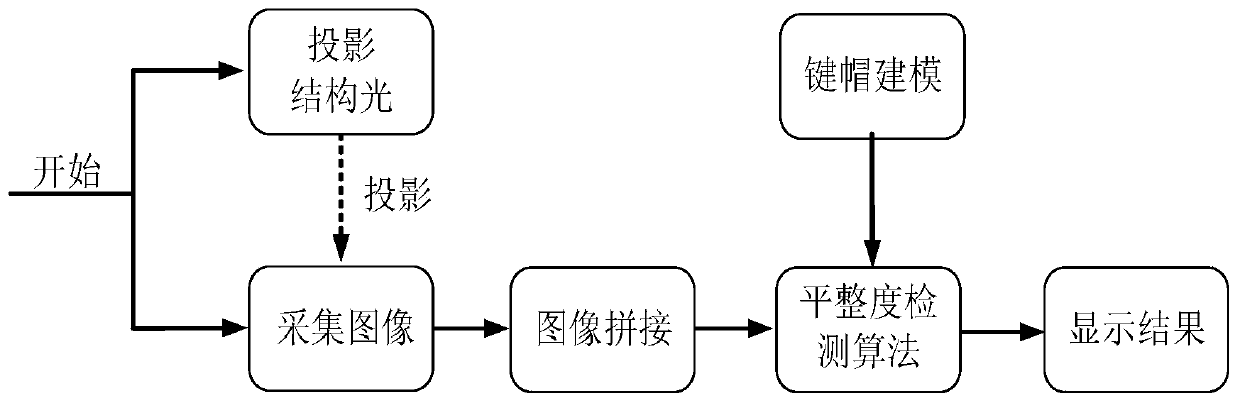

[0061] Such as Figure 1 to Figure 4 As shown, the keyboard keycap flatness fast measurement method based on structured light imaging of the present invention, its steps are:

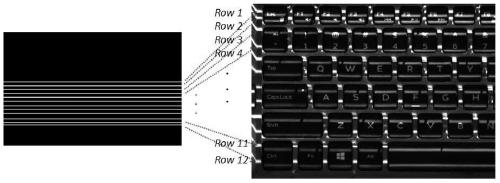

[0062] Step S1: Structured light mode design and projection, to ensure that the structured light generated by the digital projector has a clear light stripe on the upper and lower ends of each keycap surface of the keyboard to be tested;

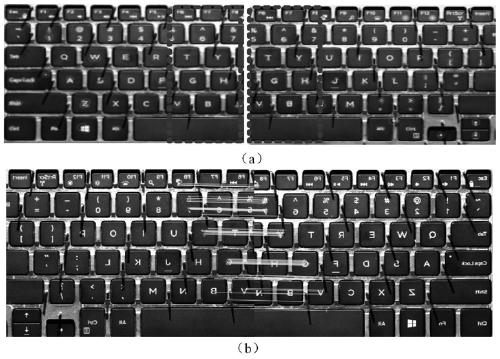

[0063] Step S2: Multiple cameras collect image sequences; after receiving the detection signal, the cameras collect keyboard image sequences encoded by structured light;

[0064] Step S3: image stitching; stitching the image sequence into a complete full-size keyboard image with high resolution;

[0065] Step S4: Keycap modeling; relying on manual acquisition of the keycap mask and the position information of each keycap in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com