Double-layer concave structure terahertz ring dipole metamaterial

A terahertz ring-couple, double-layer concave technology, applied in the structural form of radiating elements, antennas, electrical components, etc., can solve the problems of inability to directly verify the correctness of the theory, no metamaterials are prepared, and achieve adjustable and enhanced resonant frequency. The effect of front incident intensity and high Q value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the present invention is a photolithography method and a vacuum thermal evaporation method, comprising the steps of:

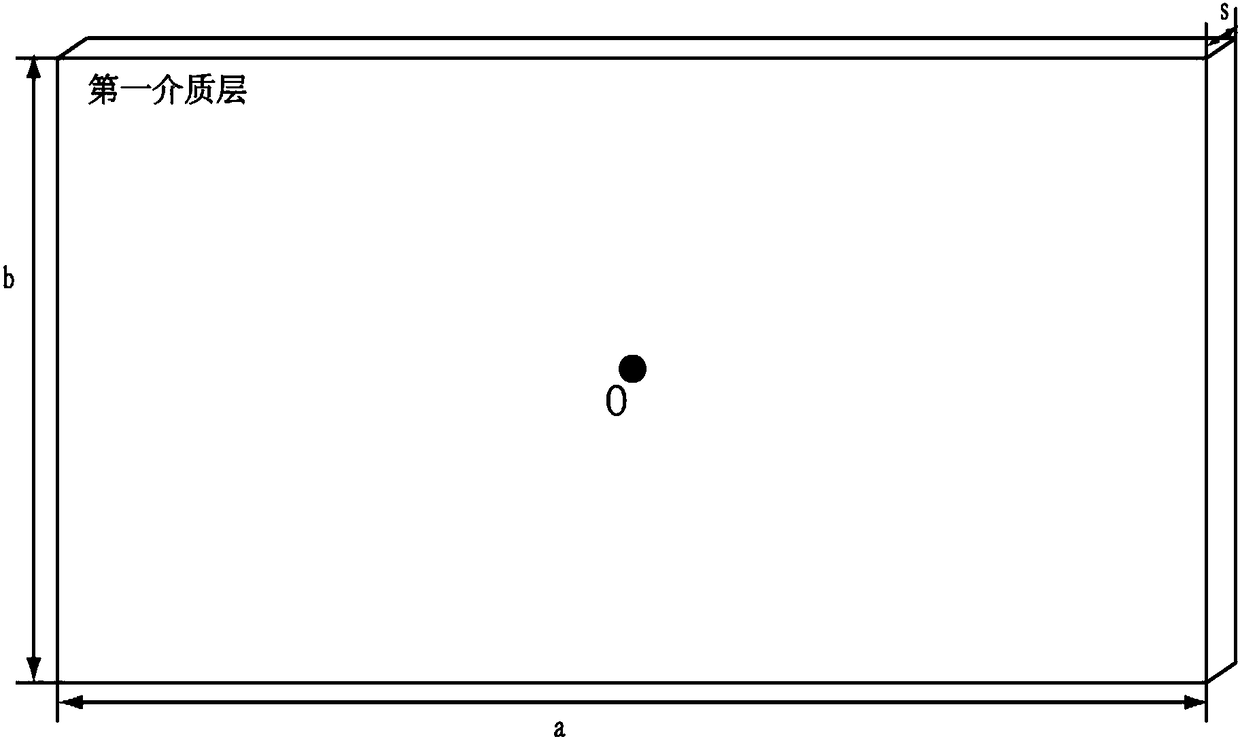

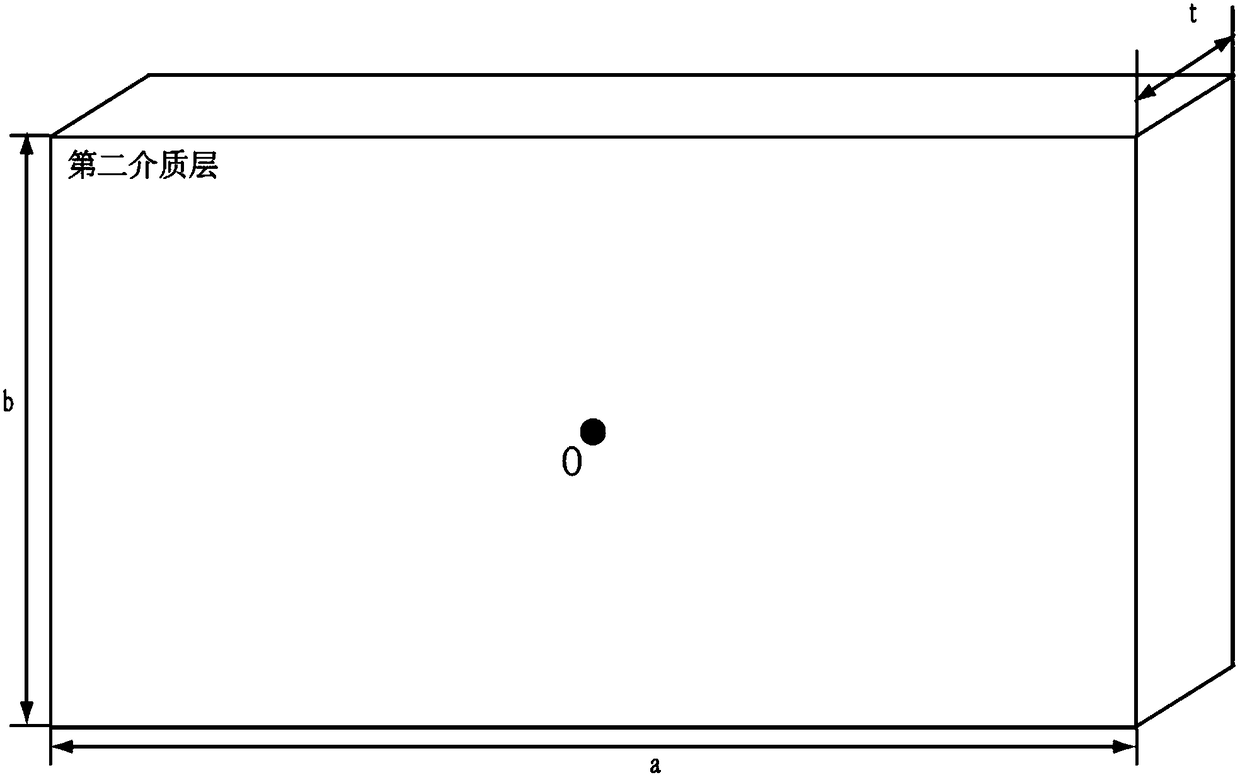

[0030] (1) Preparation of the first layer of polyimide: cleaning and dehydrating the silicon wafer and forming a base film on the surface of the silicon wafer; using a glue-spinning machine to coat polyimide acid on the treated silicon wafer, and then the sample Put it in a high-temperature oven for the imidization process of the film. The specific imidization process conditions are as follows: heat the silicon wafer coated with polyimide acid from room temperature to 90-110°C and keep it for 25-35min; heat it to 190°C ~210°C, keep for 25-35min; heat to 290-310°C, keep for 25-35min; finally, heat to 330-365°C, and keep for 50-90min. After this step, the first dielectric layer can be obtained, which has a length of 168 μm-294 μm, a width of 104 μm-182 μm, and a thickness of 4 μm-8 μm.

[0031] (2) Preparation of the first layer...

Embodiment 1

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, and the present invention is not limited to the following examples.

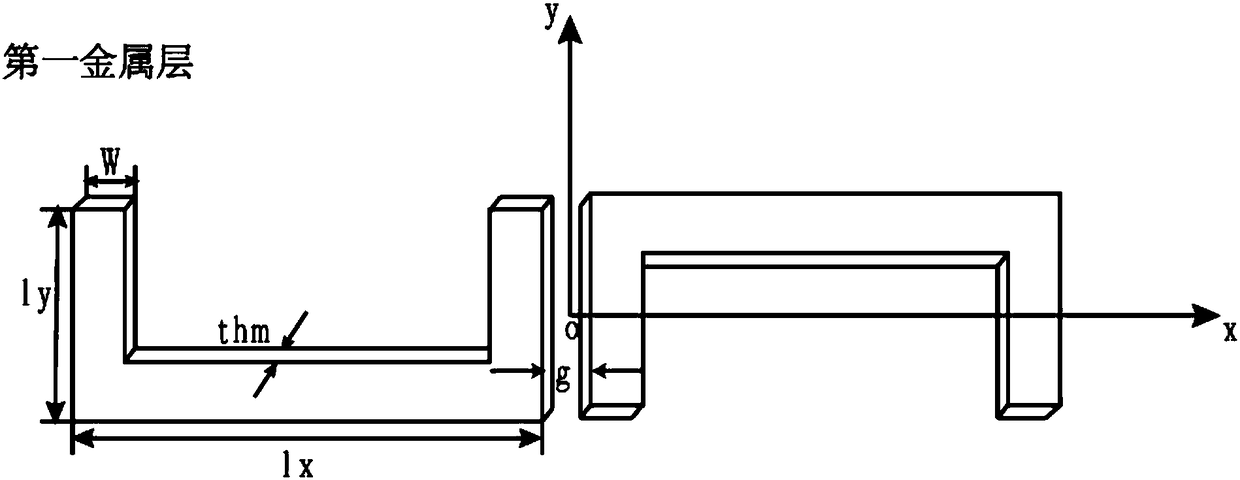

[0036] Such as Figure 1-6 As shown, the four-layer structure of the metamaterial model takes the geometric center of each layer as the origin. The arrangement shape of each metal layer is as follows: the opening directions of two adjacent concave shapes in a row are opposite, and the upper and lower row structures are consistent; the distance between two opposite concave metal structures symmetrical to the center is g=-5 μm, and the outer length of the concave structure and width are lx=150μm and ly=77μm respectively; the length and width inside the concave structure are lx-w=132μm and ly-w=68μm respectively; the thickness is thm=0.2μm; all the concave metal structures have the same size, distance Equal; the distance between the first metal layer of the concave structure and the fir...

Embodiment 2

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, and the present invention is not limited to the following examples.

[0045] Such as Figure 1-6 As shown, the four-layer structure of the metamaterial model takes the geometric center of each layer as the origin. The arrangement shape of each metal layer is: the opening directions of two adjacent concave shapes in a row are opposite, and the upper and lower row structures are consistent; the distance between two opposite concave metal structures symmetrical to the center is g=0μm, and the outer length of the concave structure and The widths are lx=151μm and ly=79μm; the length and width inside the concave structure are lx-w=128μm and ly-w=67.5μm; the thickness is thm=0.3μm; all the concave metal structures have the same size, the distance Equal; the distance between the first metal layer of the concave structure and the first dielectric bottom layer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com