Method for filtering and treating wastewater from livestock and poultry slaughter houses

A treatment method and technology for wastewater treatment, applied in the field of wastewater treatment in livestock and poultry slaughterhouses, can solve the problems of complex treatment procedures, large amount of drugs added, and high treatment costs, and achieve the effects of simple process, excellent efficacy and strong adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 and embodiment 2 were all carried out a small test at the front end of the small waste water treatment pool at the waste water treatment field of Xuzhou Xinyi Zhongke Food Co., Ltd.

[0024] Example 1

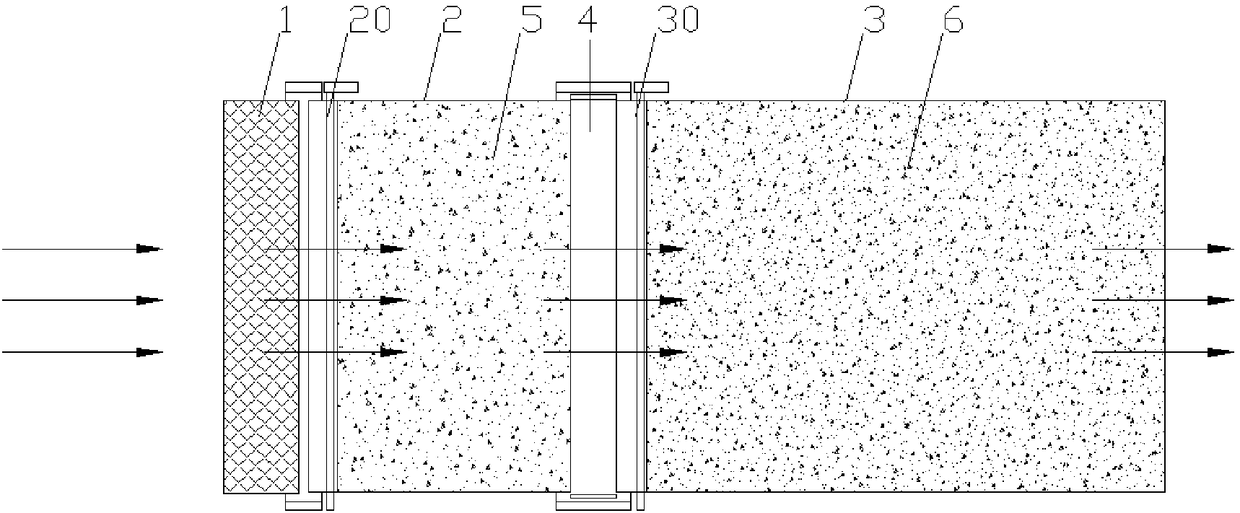

[0025] Such as figure 1 , a method for filtering and treating wastewater from livestock and poultry slaughterhouses, which is arranged before the biological or chemical treatment stage of existing wastewater treatment plants from livestock and poultry slaughterhouses, comprising the following steps:

[0026] (1) After the waste water treatment pool, install a block 1, the material of block 1 is plastic, the diameter of the mesh of block 1 is determined according to the solid waste composition of livestock and poultry slaughterhouse wastewater, the range is 0.5-5mm, and the rear end of the block is set in sequence The first filter gate 2, the second filter gate 3, the front ends of the first filter gate 2 and the second filter gate 3 are respectively provide...

Embodiment 2

[0035] Such as figure 1 , a method for filtering and treating wastewater from livestock and poultry slaughterhouses, which is arranged before the biological or chemical treatment stage of existing wastewater treatment plants from livestock and poultry slaughterhouses, comprising the following steps:

[0036] (2) After the waste water treatment pool, install a block 1, the material of block 1 is plastic, the diameter of the mesh of block 1 is determined according to the solid waste composition of livestock and poultry slaughterhouse wastewater, the range is 0.5-5mm, and the rear end of the block is set in sequence The first filter gate 2, the second filter gate 3, the front ends of the first filter gate 2 and the second filter gate 3 are respectively provided with a first gate 20, a second gate 30, the first filter gate 2, There is a gap section 4 between the second filter gates 3; the first rice powder material layer 5 and the second rice powder material layer 6 are respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com