A kind of soybean protein isolate multi-stage extraction method and system

A soybean protein isolate and extraction technology, applied in the field of soybean protein isolate multi-stage extraction methods and systems, can solve the problems of low solubility, heavy protein smell and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

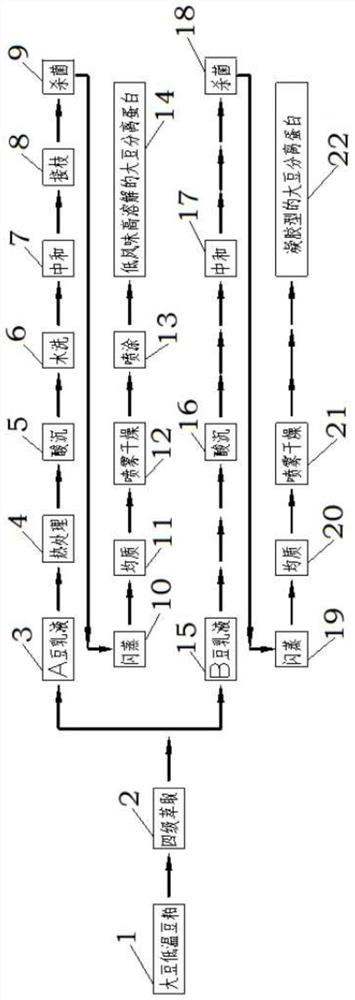

Image

Examples

preparation example Construction

[0046] Specifically, the preparation method of soybean meal includes: using non-transgenic soybeans or / and genetically modified soybeans as raw materials, obtaining soybeans through purification, softening, crushing, peeling, heat treatment, embryo pressing, extraction, low-temperature vacuum precipitation and drying, Among them, the protein content of soybean meal is 54.5-55.5%, and the NSI (nitrogen solubility index) is 85.5-86.5.

[0047] Specifically, the polysaccharide specifically includes: one or more of soybean polysaccharide, lactose and starch sugar, and the polysaccharide accounts for 0.3-0.5% of the mass percentage of the neutral protein milk.

[0048] Preferably, the polysaccharide is soybean polysaccharide, and soybean polysaccharide accounts for 0.5% of the mass percentage of neutral protein milk.

[0049] Specifically, the heating temperature in step 3 is 105° C. to 120° C., and the heating time is 3 to 5 minutes.

[0050] Among them, the heat-treated A soybea...

Embodiment 1

[0058] The present embodiment provides the soybean protein isolate multistage extraction method, specifically comprises the following steps:

[0059] 1. Use soybean low-temperature soybean meal as raw material, wherein the protein content of soybean meal is 55.5%, and NSI is 85.8. Measure and control the amount of low-temperature soybean meal to 3 tons / hour, adjust the water temperature of the process water to 49±1°C, perform primary extraction according to the water-material ratio of 5:1, add water 15 tons / hour, and the pH value at this time is 7.02 after testing , control the material level of the tank, and use a centrifuge to separate the solid and liquid after leaching time (including the tube bundle time) for 25 minutes to obtain a soaked soybean emulsion and a soaked soybean dregs.

[0060] 2. The bean dregs from the first soaking process are directly put into the second soaking tank, and the temperature of the process water is adjusted to 49±1°C, and the secondary extra...

Embodiment 2

[0069] This embodiment provides a soybean protein isolate multistage extraction method, which is basically the same as in Example 1, specifically as follows

[0070] 1. Use soybean low-temperature soybean meal as raw material, in which the protein content of soybean meal is 55.3%, NSI is 86.5, set and control the amount of low-temperature soybean meal to 3 tons / hour, adjust the water temperature of the process water to 49±1°C, according to the water material of 4.5:1 Compared with carrying out primary extraction, add water 13.5 tons / hour, the pH value at this moment is detected as 7.22, the material level of control tank, leaching time (including tube bundle time) utilizes centrifuge solid-liquid separation after 25 minutes, obtains a leaching Soy milk and a dip in okara.

[0071] 2. The bean dregs from the first soaking process are directly put into the second soaking tank, the water temperature of the process water is adjusted to 49±1°C, and the secondary extraction is carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com