Method for preparing water chestnut whole powder by superheated steam and hot air combined-drying

A technology of combined drying and superheated steam, applied in food drying, drying gas arrangement, lighting and heating equipment, etc., can solve the problems of high production cost, low cost, material cell damage, etc. The effect of simplifying the machining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

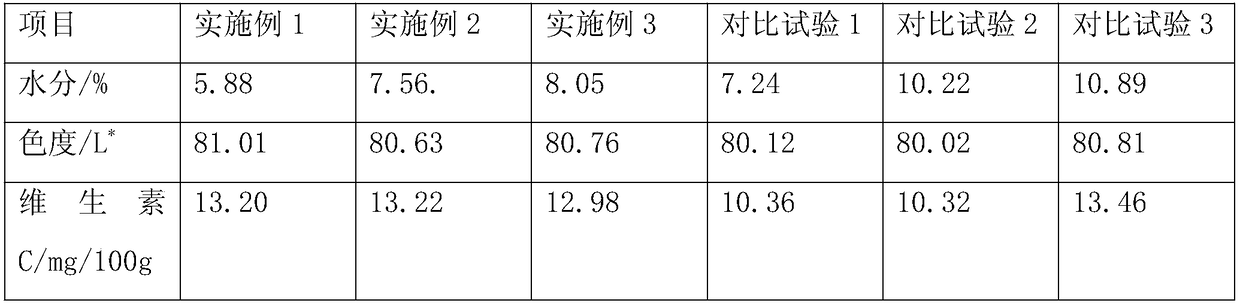

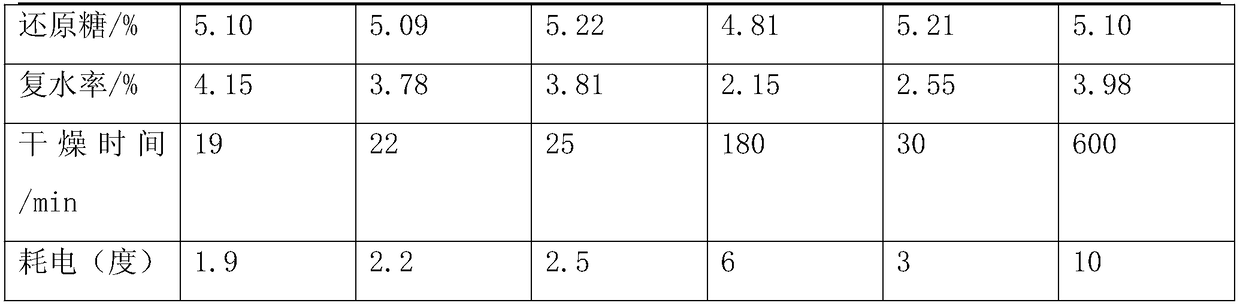

Embodiment 1

[0019] A kind of superheated steam and the method for preparing water chestnut whole powder by combined drying of hot air, comprise the following steps:

[0020] Select mature water chestnut, peel and cut into 0.5cm thin slices, drain the water quickly after washing, lay it flat on the drying tray, and directly put it into the hot steam-hot air integrated drying equipment, the temperature is 180°C, and the wind speed is 8m / s , the pressure is 7Mpa, when the moisture content of the wet basis at the drying conversion point is 21%, turn off the hot steam generator, restore the pressure to normal, and carry out hot air drying at a wind speed of 5m / s and a temperature of 70°C until the moisture content is 6 %. Dried slices are crushed through an 80-mesh sieve, packaged, and finished.

Embodiment 2

[0022] A kind of superheated steam and the method for preparing water chestnut whole powder by combined drying of hot air, comprise the following steps:

[0023] Select mature water chestnuts, peel and cut into 0.5cm slices, drain the water quickly after washing, lay flat on the drying tray, and directly put them into the hot steam-hot air integrated drying equipment, temperature: 170 ° C, wind speed 7m / s, the pressure is 6Mpa, and when the moisture content of the wet basis at the drying conversion point is 22%, turn off the hot steam generator, restore the pressure to normal, and carry out hot air drying at a wind speed of 5m / s and a temperature of 85°C until the moisture content is 8 %. Dried slices are crushed through an 80-mesh sieve, packaged, and finished.

Embodiment 3

[0025] A kind of superheated steam and the method for preparing water chestnut whole powder by combined drying of hot air, comprise the following steps:

[0026] Select mature water chestnuts, peel and cut into 0.5cm thin slices, drain the water quickly after washing, lay flat on the drying tray, and directly put them into the hot steam-hot air integrated drying equipment, temperature: 165 °C, wind speed 6m / s, the pressure is 6Mpa, and when the moisture content of the wet base at the drying conversion point is 26%, turn off the hot steam generator, restore the pressure to normal, and carry out hot air drying at a wind speed of 5m / s and a temperature of 90°C until the moisture content is 8 %. Dried slices are crushed through an 80-mesh sieve, packaged, and finished.

[0027] Comparative test 1

[0028] The whole water chestnut powder is dried with hot air, the difference is that the water chestnut slices are pretreated for color protection, steamed, and then dried by a singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com