Desulfurizing system and method for biogas containing high-concentration hydrogen sulfide

A desulfurization system, hydrogen sulfide technology, applied in chemical instruments and methods, separation methods, gas treatment and other directions, can solve the problems of energy waste and high operating costs, achieve low operating costs, save the cost of desulfurization agents, and realize the effect of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

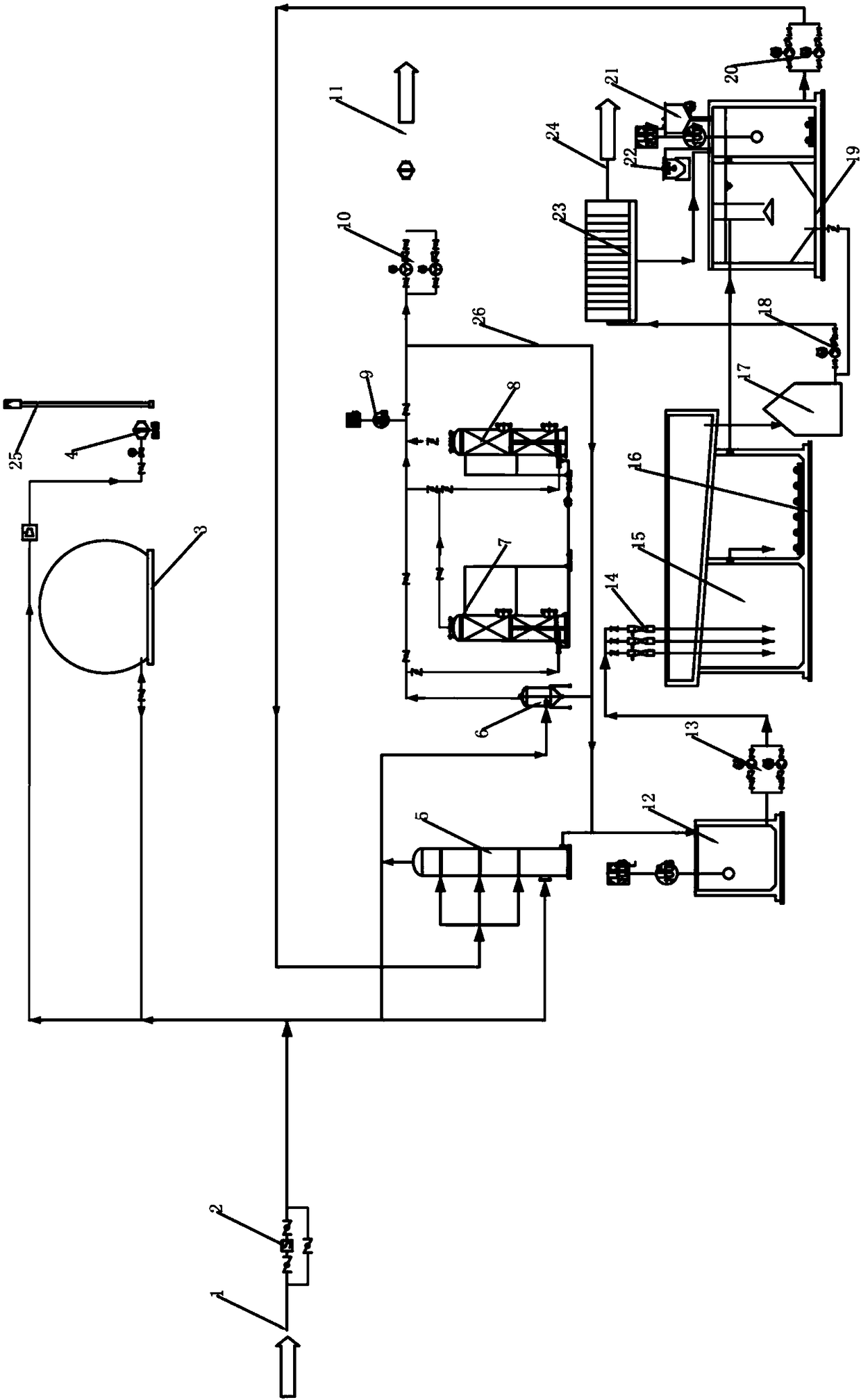

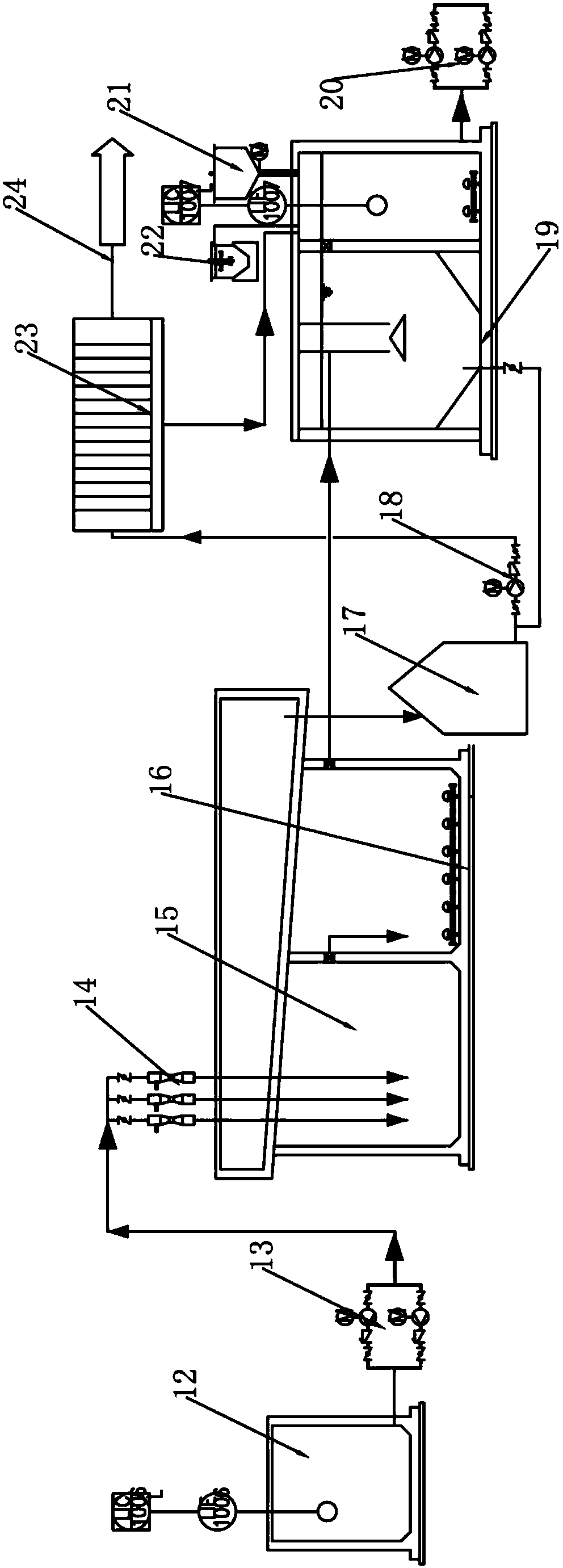

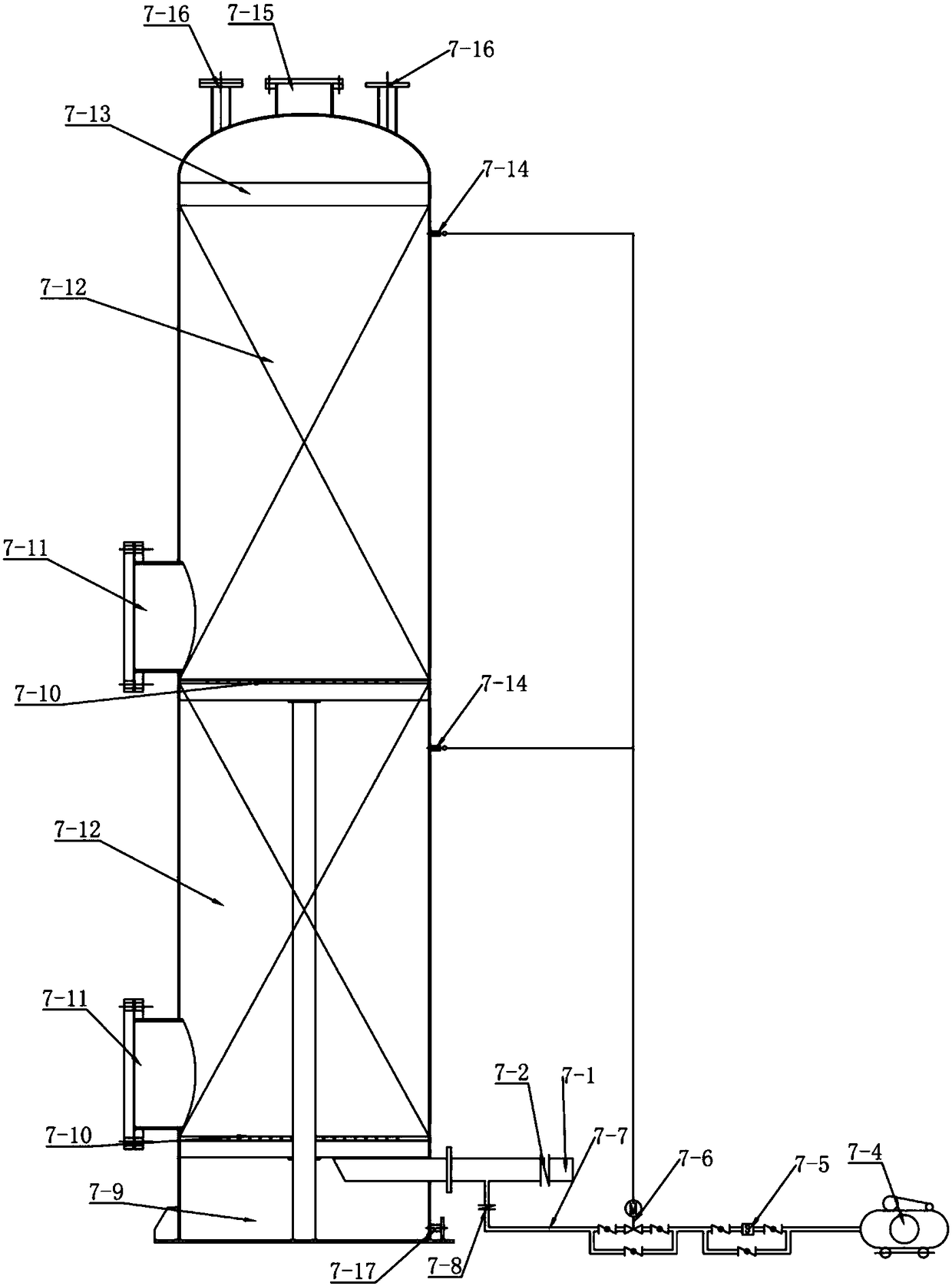

[0038] Such as Figure 1-5 As shown, a desulfurization system for biogas containing high-concentration hydrogen sulfide, including biogas inlet 1, biogas flow meter 2, biogas cabinet 3, wet desulfurization tower, gas-water separator 6, several series or Parallel dry desulfurization tower, outlet gas detector 7-17, biogas blower 10 and biogas utilization pipeline 11, the spray liquid treated by the wet desulfurization tower 5 and the liquid of the gas-water separator 6 all enter the desulfurization liquid for regeneration Processing device, the desulfurization liquid regeneration processing device includes a rich liquid pool 12, a regeneration pool 1915 and a lean liquid pool 19 connected in sequence, and the lean liquid pool 19 communicates with the wet desulfurization tower 5 through a wet tower spray pump 20 , the regeneration tank 15 is provided with a jet pump 13, a jet device 14, and an aerator 16, and the regeneration tank 1915 is connected with a sulfur foam collector 1...

Embodiment 2

[0059] A kind of desulfurization method that contains high-concentration hydrogen sulfide biogas, adopts the desulfurization system of embodiment 1, comprises the following steps:

[0060] (1) The biogas produced by the anaerobic pond enters the biogas tank from the biogas inlet through the first biogas flowmeter, and after being temporarily stored in the biogas tank, it enters the wet desulfurization tower; in this tower, the biogas runs from bottom to top, and from top to top After the desulfurization spray liquid under contact, react to remove 90-98% of the hydrogen sulfide in the biogas, and the biogas after the removal of hydrogen sulfide enters the gas-water separator, in the gas-water separator, the biogas and water are separated Separation, the separated biogas enters the dry desulfurization tower, the hydrogen sulfide content in the biogas after dry desulfurization is reduced to below 100ppm, and after being pressurized by the biogas fan, it can enter the biogas utiliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com