Steering sensor assembly

A technology of steering sensors and components, applied in steering mechanisms, vehicle parts, transportation and packaging, etc., can solve the problems of elastic buckle damage, difficult processing, complex structure, etc., and achieve no rebound, good repeatability, and anti-interference powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

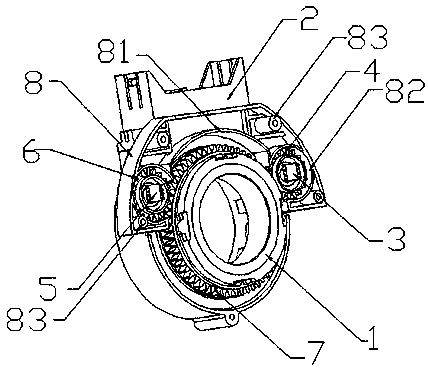

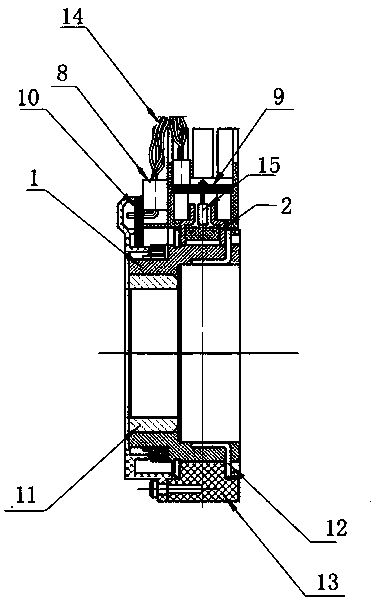

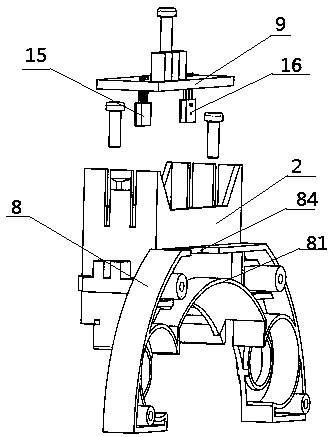

[0017] Such as figure 1 Shown: a steering sensor assembly of the present invention; including a gear ring assembly 1, a conduction assembly 2, a Hall chipset and a circuit board; the gear ring assembly 1 is mated with the conduction assembly 2; the circuit board includes an angle circuit Plate 10 and torque circuit board 9; the Hall chip group includes Hall chip one 3, Hall chip two 5, Hall chip three 15 and Hall chip four 16; the Hall chip three 15 and Hall chip Four 16 are connected with the torque circuit board 9 respectively, and the torque circuit board 9 is matched and installed on the conduction assembly 2; the side of the ring gear assembly 1 is provided with a large gear 7 that is connected with the gear assembly 1; Pinion one 4 and pinion two 6 are arranged symmetrically at the middle and upper positions of both sides of the gear 7, and pinion one 4 and pinion two 6 are engaged with the bull gear 7 respectively; 6. The rear part is matched with a rear fixed plate 8;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com