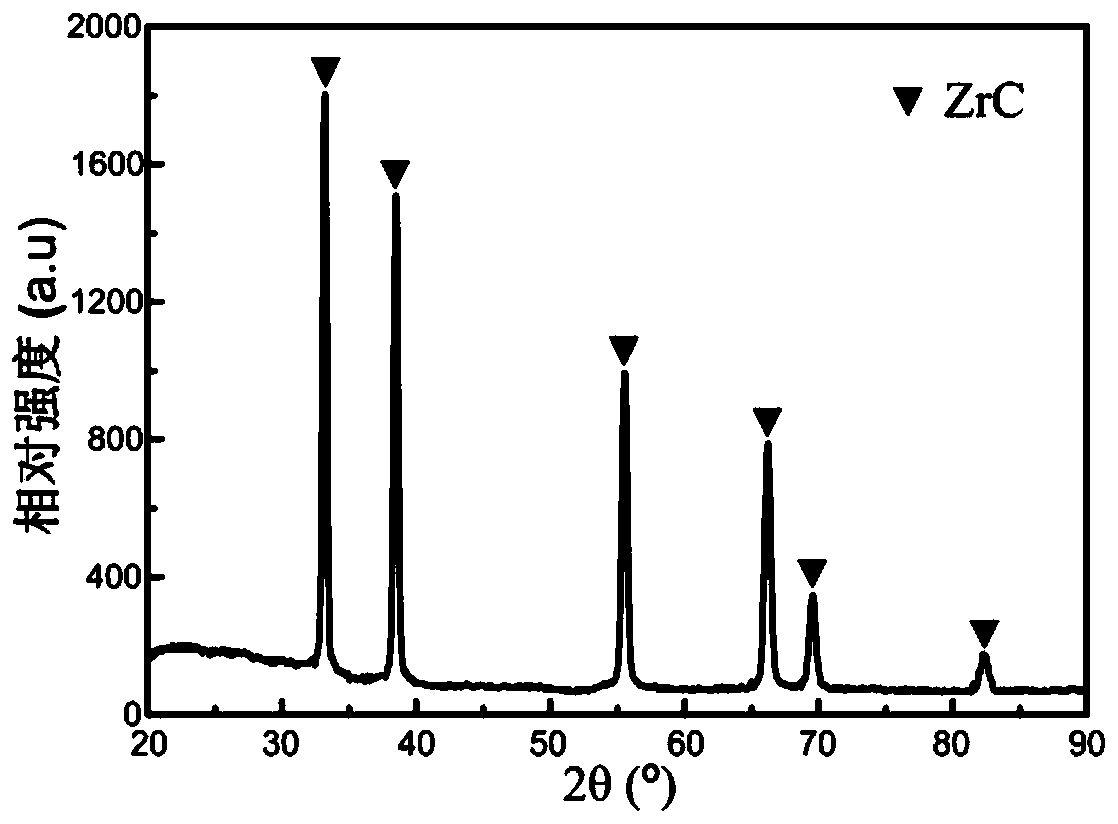

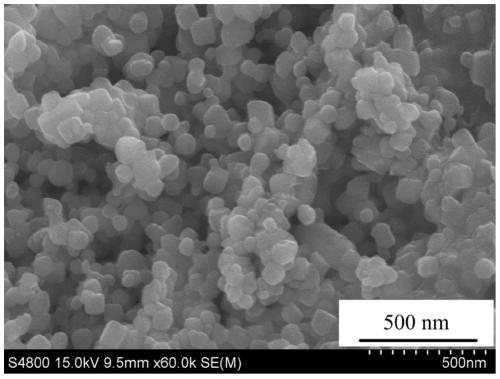

A kind of in-situ synthesis method of zirconium carbide nanopowder

A nano-powder, in-situ synthesis technology, used in carbon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of organic solvent toxicity and high cost, and achieve the effects of simple operation, convenient operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for in-situ synthesis of zirconium carbide nanopowder, the preparation process of which is:

[0036] 1. Weighing: Weigh Cu powder with a particle size of ~0.5μm, Zr powder with a particle size of ~45μm, and graphite powder with a particle size of ~100nm in a molar ratio of 0.4:1:1, and the raw materials used are all commercial powders;

[0037] 2. Mixing materials: Put the weighed Cu powder, Zr powder, C powder, and grinding balls and ball milling tanks into a vacuum glove box. Put the balls and powder into the ball mill jar in the gas environment, and then put the sealed ball mill jar into the roller ball mill and mix for 10 hours, wherein the balls are ZrO 2 Grinding balls, the weight ratio of grinding balls to powder is 10:1, and the rotating speed of the ball mill is 60 rpm;

[0038] 3. Loading: Put the mixed Cu-Zr-C powder into Al 2 o 3 In the ceramic boat, then put the ceramic boat with the powder into the high-temperature tubular atmosphere furnace. A...

Embodiment 2

[0044] A method for in-situ synthesis of zirconium carbide nanopowder, the preparation process of which is:

[0045] 1. Weighing: Weigh Cu powder with a particle size of ~0.5μm, Zr powder with a particle size of ~45μm, and graphite powder with a particle size of ~100nm in a molar ratio of 0.69:1:1, and the raw materials used are all commercial powders;

[0046] 2. Mixing materials: Put the weighed Cu powder, Zr powder, C powder, and grinding balls and ball milling tanks into a vacuum glove box. Put the balls and powder into the ball mill jar in the gas environment, then put the sealed ball mill jar into the roller ball mill and mix for 14 hours, wherein the balls are ZrO 2 Grinding balls, the weight ratio of the grinding balls to the powder is 10:1, and the rotating speed of the ball mill is 50 rpm;

[0047] 3. Loading: Put the mixed Cu-Zr-C powder into Al 2 o 3 In the ceramic boat, then put the ceramic boat with the powder into the high-temperature tubular atmosphere furna...

Embodiment 3

[0051] A method for in-situ synthesis of zirconium carbide nanopowder, the preparation process of which is:

[0052] 1. Weighing: Weigh Cu powder with a particle size of ~75 μm, Zr powder with a particle size of ~45 μm, and graphite powder with a particle size of ~6.5 μm in a molar ratio of 0.4:1:1, and the raw materials used are all commercial powders;

[0053] 2. Mixing materials: Put the weighed Cu powder, Zr powder, C powder, and grinding balls and ball milling tanks into a vacuum glove box. Put the balls and powder into the ball mill jar in the gas environment, and then put the sealed ball mill jar into the roller ball mill and mix for 10 hours, wherein the balls are ZrO 2 Grinding balls, the weight ratio of the grinding balls to the powder is 10:1, and the rotating speed of the ball mill is 70 rpm;

[0054] 3. Loading: Put the mixed Cu-Zr-C powder into Al 2 o 3 In the ceramic boat, then put the ceramic boat with the powder into the high-temperature tubular atmosphere ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com