Clinker-free high-performance cement prepared from metallurgical slag

A clinker-free, high-performance technology, applied in cement production, etc., can solve problems such as polluting the environment and destroying the natural environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

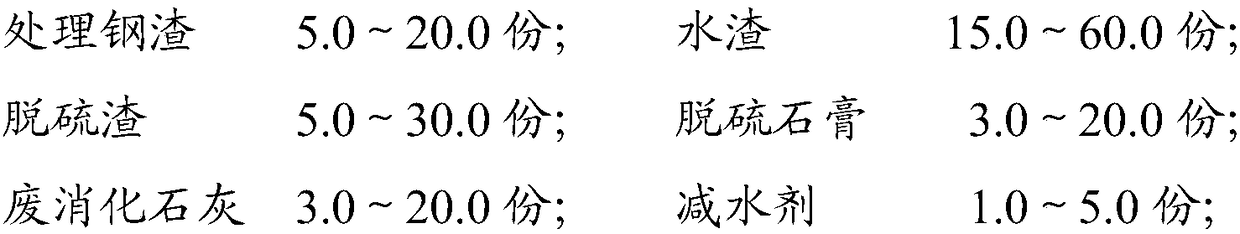

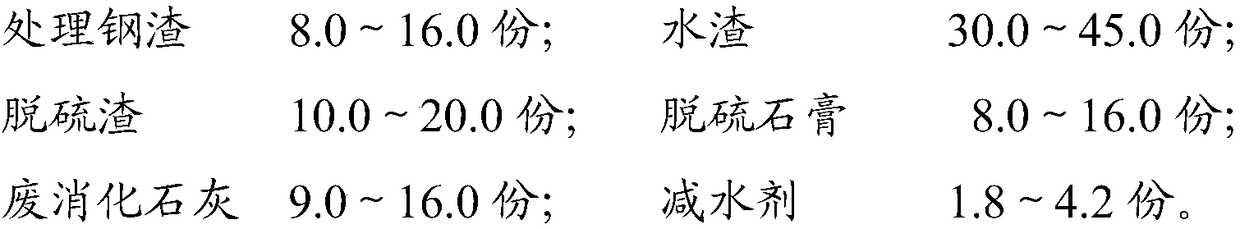

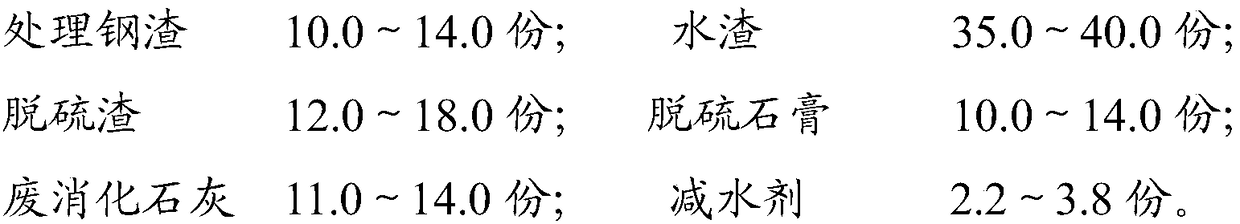

Method used

Image

Examples

Embodiment 1

[0075] Embodiment 1: Preparation of clinker-free high-strength cement of the present invention

[0076] The implementation mode of this embodiment is as follows:

[0077] Use the processing steel slag obtained by the No. 3 steelmaking plant of Wuhan Iron and Steel Group during steelmaking, adopt the method described in CN101280346B to process, and have an iron content of 0.05% by weight; ; the water slag obtained by the ironmaking plant of Wuhan Iron and Steel Group when the molten iron in the ironmaking plant is desulfurized; the desulfurized gypsum provided by the second steelmaking plant of Wuhan Iron and Steel Group, the waste digested lime provided by the second steelmaking plant of Wuhan Iron and Steel Group, and the Lignosulfonate sold by Tingruo Chemical Company under the trade name Shanghai Tingruo; the specific surface area of the steel slag, water slag, desulfurization slag, desulfurization gypsum, waste digested lime and water reducing agent is 350-450m 2 / kg, p...

Embodiment 2

[0082] Embodiment 2: Preparation of clinker-free high-strength cement of the present invention

[0083] The implementation mode of this embodiment is as follows:

[0084] Use the processing steel slag obtained by Ningbo Steel Works during steelmaking, adopt the method described in CN101280346B to process, and have an iron content of 0.30% by weight; water slag obtained by Ningbo Steel Works during ironmaking; Desulfurization slag obtained from desulfurization treatment in iron works before molten iron enters the converter; desulfurization gypsum provided by Ningbo Steel Works, waste digested lime provided by Ningbo Steel Works, naphthalene sold under the trade name Zhe Chuang by Shangyu Zhechuang Chemical Co., Ltd. Sulfonate formaldehyde polymer; the specific surface area of the treated steel slag, water slag, desulfurization slag, desulfurization gypsum, waste digested lime and water reducing agent is 450-550m 2 / kg, particle size gradation is 20% by weight if the particle...

Embodiment 3

[0089] Embodiment 3: Preparation of clinker-free high-performance cement of the present invention

[0090] The implementation mode of this embodiment is as follows:

[0091] Use the treatment electric furnace slag obtained by Daye Iron and Steel Co., Ltd. during electric furnace steelmaking, adopting the method described in CN101280346B, and having an iron content of 0.22% by weight; water slag obtained by Echeng Iron and Steel Company during ironmaking ; Desulfurization slag obtained by Echeng Iron and Steel Company from the desulfurization treatment of molten iron before entering the converter; desulfurization gypsum obtained by Baosteel during desulfurization of molten steel, waste digested lime provided by Wuhan Iron and Steel Group Iron Plant, and Shanghai Qinhe The melamine-based water reducer sold by the Chemical Co., Ltd. under the trade name Qinhe Chemical; the specific surface area of the steel slag, water slag, desulfurization slag, desulfurization gypsum, waste d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com