Method for preparing o-chlorotoluene

A technology for o-chlorotoluene and dichlorotoluene, applied in the field of catalytic reduction to prepare o-chlorotoluene, can solve problems such as product waste, and achieve the effects of long service life and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. The specific surface area of 25g is greater than 100m 2 / g, silicon carbide cylindrical particles with a diameter of 2-4mm, impregnated and adsorbed with 10ml of aqueous solution containing 5% tetraammonium palladium chloride, dried naturally at 110°C for 5 hours before use.

[0022] 2. Fill 25g of hydrogenation catalyst in a cylindrical reactor with a diameter of 20mm, raise the temperature to 200°C, and keep the hydrogen atmosphere after passing hydrogen for one hour; keep the reaction pressure at 0.05MPa, and continuously add 2,3-dihydrogen at 0.3ml / h The mixture of chlorotoluene, 2,4-dichlorotoluene and 2,5-dichlorotoluene was sampled after reacting for 1 hour and analyzed by gas chromatography.

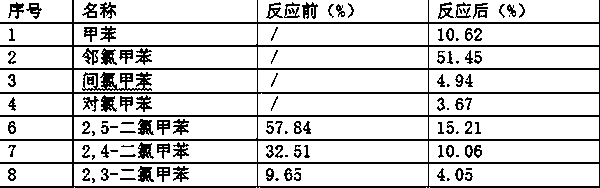

[0023] The result is as follows:

[0024]

Embodiment 2

[0026] The mixture of 2,3-dichlorotoluene, 2,4-dichlorotoluene and 2,5-dichlorotoluene in Example 1 was replaced by 2,5-dichlorotoluene, and the others were the same as in Example 1.

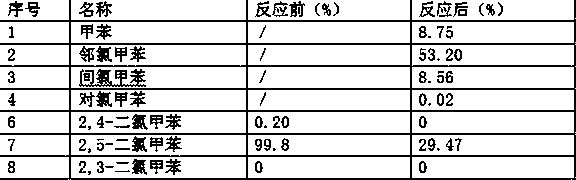

[0027] The result is as follows:

[0028]

Embodiment 3

[0030] The silicon carbide-supported palladium catalyst in Example 1 was replaced by an activated carbon-supported palladium catalyst, and the others were the same as in Example 1.

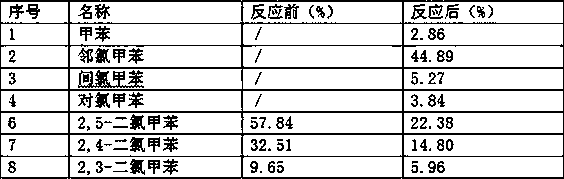

[0031] The result is as follows:

[0032]

[0033] It can be seen that the activated carbon-supported palladium catalyst has a catalytic selectivity effect inferior to that of the silicon carbide-supported palladium catalyst, and industrial production preferably selects the activated carbon-supported palladium catalyst provided by the invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com