Full-bio-based toughened polylactic acid composite and preparation method thereof

A composite material and tough polylactic acid technology, applied in the field of composite materials, can solve problems such as the performance decline of composite materials, and achieve the effects of improving thermal/mechanical properties, reducing material performance instability, and enhancing reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of full bio-based toughened polylactic acid composite material, comprises the steps:

[0028] (1) Maleic anhydride modified lignin

[0029] Weigh 10g of lignin and add it to 50mL of deionized water, stir to dissolve, precipitate it with 2M hydrochloric acid solution, centrifuge to obtain lignin solid, then wash the precipitate with deionized water repeatedly for 3 to 5 times, and finally place the obtained lignin solid at 40 Dry in a vacuum oven for 12 hours at °C, store for later use, and prepare pretreated lignin.

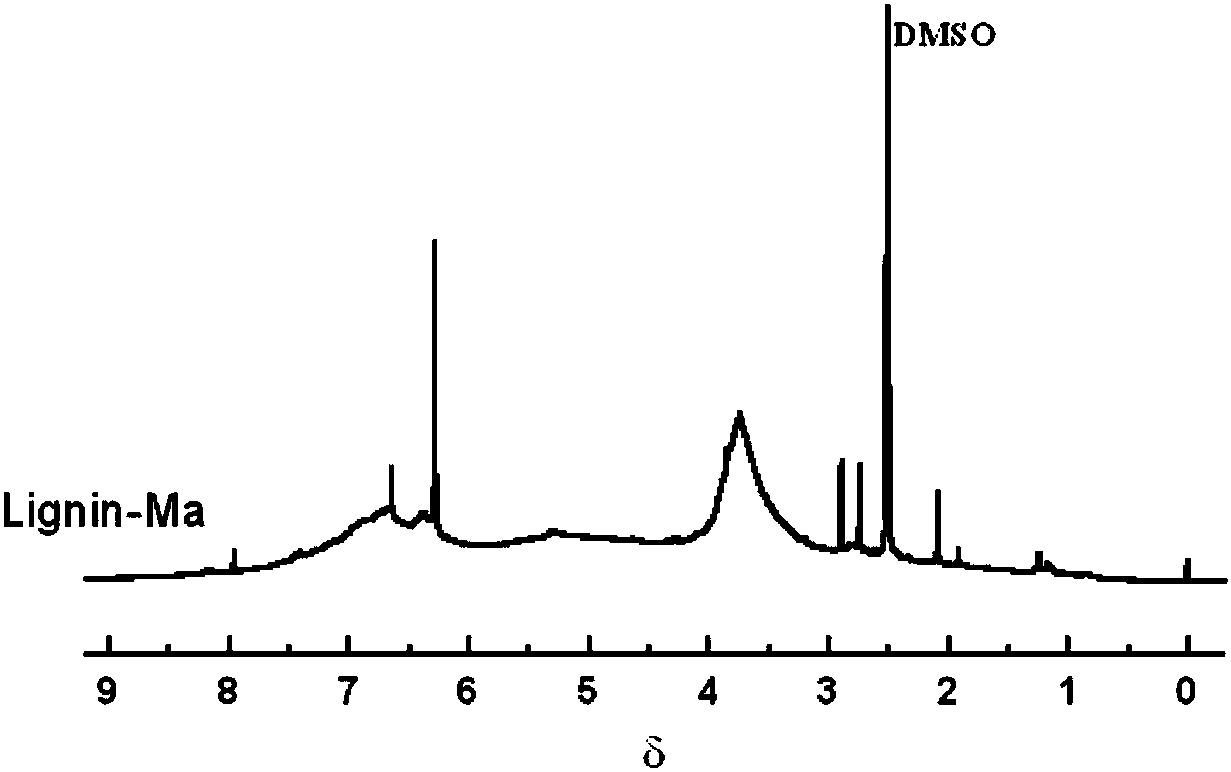

[0030] Weigh 8g of pretreated lignin and add it to 25mL of anhydrous DMF, stir evenly at 80°C, then add 10g of maleic anhydride and 10mg of 4-dimethylaminopyridine (DMAP) respectively, and react for 12h to obtain maleic anhydride-modified lignin. Prime (lignin-Ma). Its NMR spectrum is as figure 1 as shown, figure 1 The range of δ=1 to 3 in the shown H NMR spectrum is the chemical shift of the alkyl protons in the lignin str...

Embodiment 2

[0035] Example 2 (PLA / 2LM / 20ESO)

[0036] A kind of preparation method of full bio-based toughened polylactic acid composite material, comprises the steps:

[0037] (1) method is with step (1) in embodiment 1;

[0038] (2) Polylactic acid / maleic anhydride modified lignin / epoxy soybean oil composite material

[0039](a) The total mass of the fixed polylactic acid composite material is 50g, and 1g of maleic anhydride modified lignin, 10g of epoxy soybean oil and 39g of polylactic acid are weighed respectively with a mass fraction of 2% and 20%;

[0040] (b) 39g of polylactic acid and 1g of maleic anhydride modified lignin were vacuum-dried at 40°C for 12h, and then the polylactic acid and modified lignin were added to a Haake torque rheometer at 180°C Premix for 2 minutes, then add 10g epoxy soybean oil, and mix evenly for 10 minutes;

[0041] (c) The homogeneously mixed composite material was melted and hot-pressed at 190°C to obtain a polylactic acid / maleic anhydride modifi...

Embodiment 3

[0042] Example 3 (PLA / 5LM / 10ESO)

[0043] A kind of preparation method of full bio-based toughened polylactic acid composite material, comprises the steps:

[0044] (1) step is with step (1) in embodiment 1;

[0045] (2) Polylactic acid / maleic anhydride modified lignin / epoxy soybean oil composite material

[0046] (a) The total mass of the fixed polylactic acid composite material is 50g, and 2.5g maleic anhydride modified lignin, 5g epoxy soybean oil and 42.5g polylactic acid are weighed respectively with a mass fraction of 5% and 10%;

[0047] (b) Dry the weighed 42.5g polylactic acid and 2.5g maleic anhydride modified lignin in vacuum at 40°C for 12h, then add the polylactic acid and modified lignin to the Haake torque flow at 180°C Pre-mix in the variable instrument for 2 minutes, then add 5g epoxy soybean oil, and mix evenly for 10 minutes;

[0048] (c) The homogeneously mixed composite material was melted and hot-pressed at 190°C to obtain a polylactic acid / maleic anhy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com