Nylon corrugated pipe composite material for vehicle and preparation method of material

A composite material and corrugated tube technology, which is applied in the field of automotive nylon corrugated tube composite materials and its preparation, can solve the problem that the bellows cannot meet the flame retardant requirements, heat aging resistance, low temperature resistance requirements, cannot meet the requirements of the main engine factory, and cannot meet the odor. And other problems, to achieve good toughness, good toughness, low odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

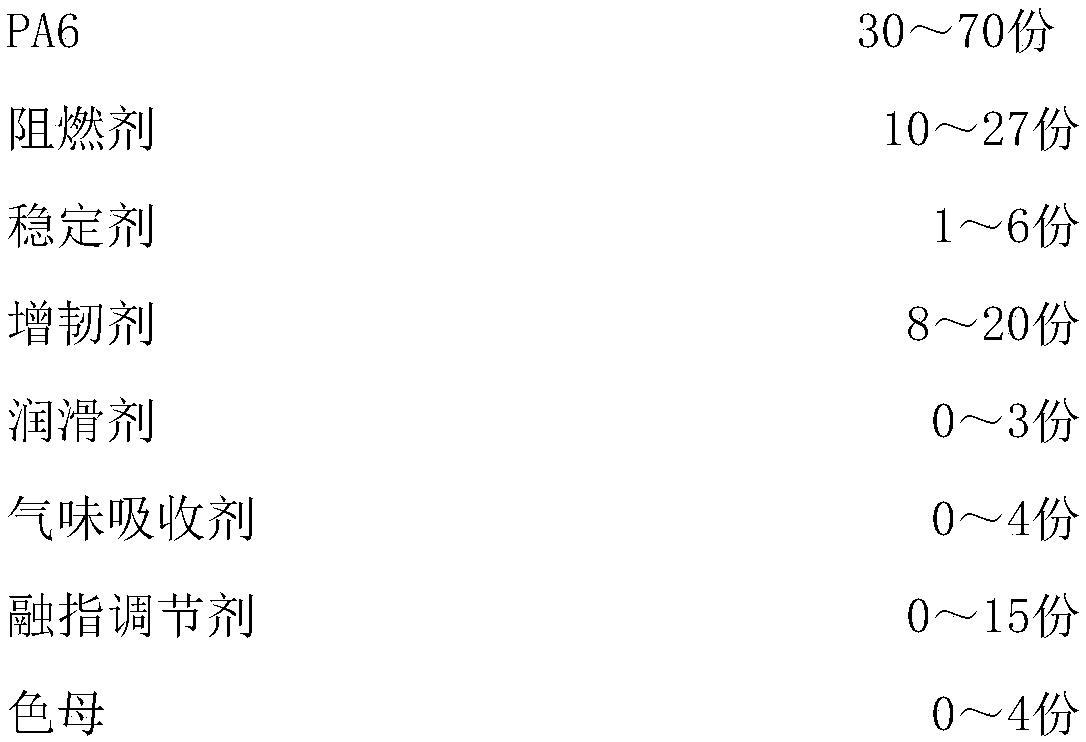

Embodiment 1

[0026] The automotive temperature nylon bellows composite material of the present embodiment is made up of the following components by weight: 51 parts of PA6, 23 parts of flame retardants, 4.7 parts of stabilizers, 12 parts of toughening agents, 2.3 parts of odor absorbers, 5 parts of Finger-melting regulator, 2 black masterbatches; among them, the flame retardant is made by mixing decabromodiphenylethane and antimony trioxide in a ratio of 17:6; the stabilizer is made of copper salt, phenols, phosphite, Ion trapping agent (quencher) and hindered amine are mixed in the ratio of 2:0.6:0.6:0.2:1.3; the toughening agent is made of maleic anhydride grafted glycidyl methacrylate and maleic anhydride grafted EPDM It is made by mixing at a ratio of 1:1; the odor adsorbent is activated clay; the melting finger regulator is made by mixing high-pressure polyethylene and metallocene polyethylene at a ratio of 1:1.

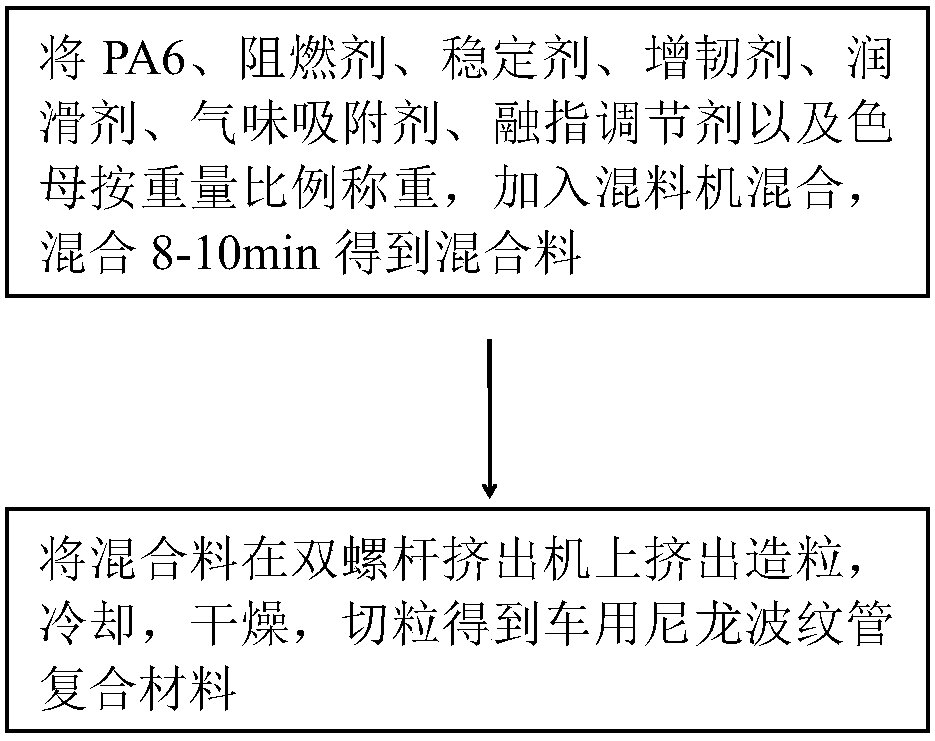

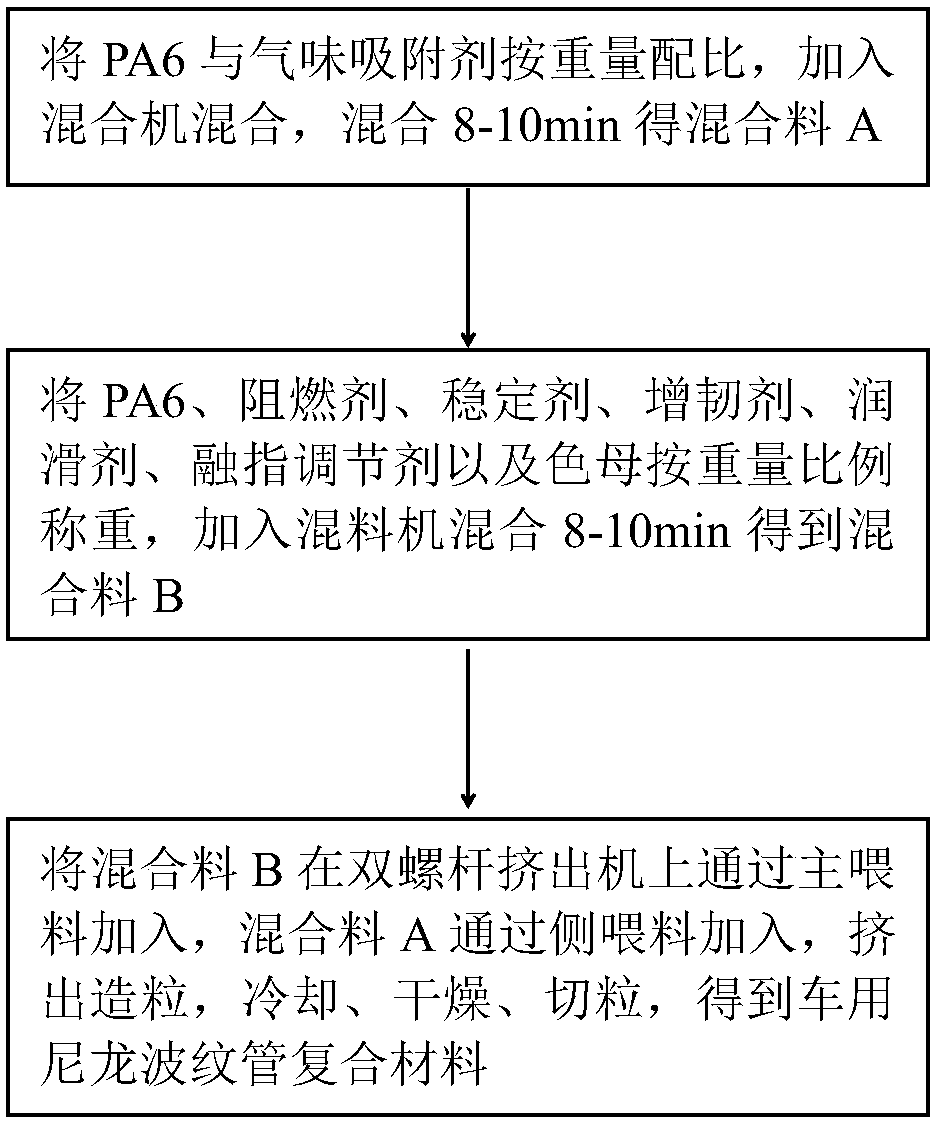

[0027] Such as figure 1 Shown, the preparation method of the automotiv...

Embodiment 2

[0033] The automotive temperature nylon bellows composite material of the present embodiment is made up of the following components by weight: 51.8 parts of PA6, 23 parts of flame retardants, 1.7 parts of stabilizers, 12 parts of toughening agents, 1.5 parts of odor absorbers, 10 parts of Melting finger regulator; wherein, the flame retardant is made by mixing decabromodiphenylethane and antimony trioxide in a ratio of 17:6; the stabilizer is made of phenols, phosphite, ion trapping agent (quencher) It is made by mixing at a ratio of 0.7:0.7:0.3; the toughening agent is made by mixing maleic anhydride grafted glycidyl methacrylate and maleic anhydride grafted EPDM at a ratio of 1:1; the odor adsorbent is activated clay ; The melt finger regulator is metallocene polyethylene.

[0034] The preparation method of the automotive nylon bellows material of this implementation is the same as that of Example 1.

Embodiment 3

[0036] The automotive nylon bellows composite material of the present embodiment is made up of the following components by weight: 51.8 parts of PA6, 23 parts of flame retardant, 3.7 parts of stabilizer, 12 parts of toughening agent, 2.5 parts of odor absorber, 5 parts Finger-melting regulator, 2 black masterbatches; among them, the flame retardant is made by mixing decabromodiphenylethane and antimony trioxide in a ratio of 17:6; the stabilizer is made of copper salt, phenols, phosphite, Ion trapping agent (quencher) and hindered amine are mixed in the ratio of 1:0.4:0.4:0.2:1.3; the toughening agent is made of maleic anhydride grafted glycidyl methacrylate and maleic anhydride grafted EPDM It is made by mixing at a ratio of 1:1; the odor absorber is made by mixing activated clay and zeolite powder at a ratio of 1:1; the melting finger regulator is made by mixing high-pressure polyethylene and metallocene polyethylene at a ratio of 1:1 .

[0037] The preparation method of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com