APAO hot melt adhesive and preparation method thereof

A hot melt adhesive, amorphous technology, used in adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problems of low cost, poor solvent resistance, poor thermal stability of EVA, etc. Low temperature, improved weather resistance, and the effect of increasing operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

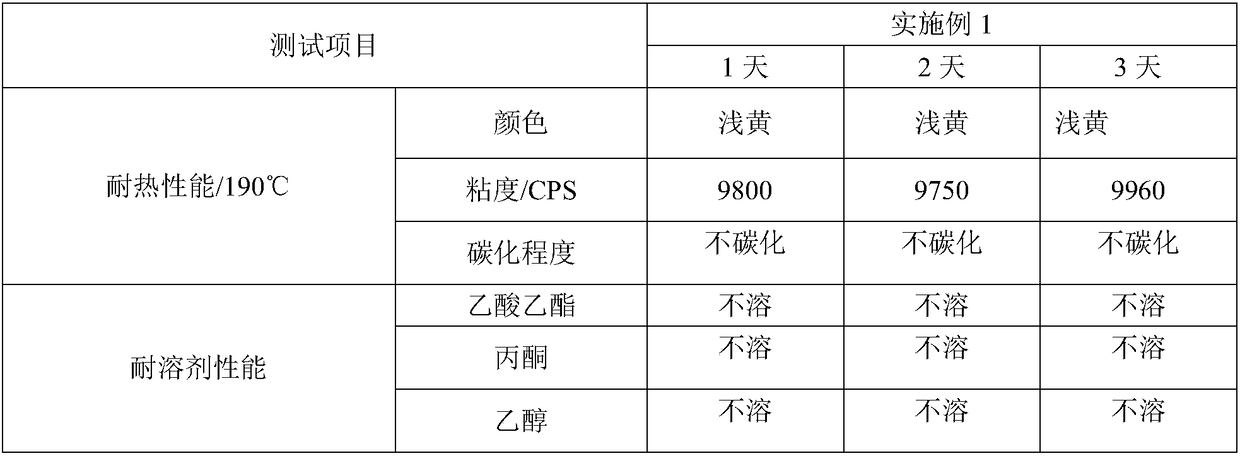

Embodiment 1

[0018] First, heat the reactor to 140°C, then add 12kg of SX-105 wax into the reactor and stir. After the SX-105 wax is completely dissolved, add 40kg of 1#5100C5 hydrogenated petroleum resin and stir again. After 1#5100C5 hydrogenated petroleum Add 0.6kg antioxidant 1010, 0.4kg antiaging agent A (antiaging agent A is produced by Tianjin Labo Auxiliaries Co., Ltd.), 14kg amorphous polymer after the dissolution of resin (1#5100C5 hydrogenated petroleum resin is produced by Exxon, USA). Olefin APAO750, heat and stir and vacuumize, keep the temperature of the material at about 145 ° C, after all the components are dissolved, then add 33kg of amorphous polyolefin APAO708, stir and vacuumize, until all components become transparent and uniform until viscous liquid is reached, then stop stirring and discharge while hot to obtain hot melt adhesive. Take 100g of the prepared hot melt adhesive and place it in a 200ml beaker, place it in an oven at 190°C, and observe the color, viscosit...

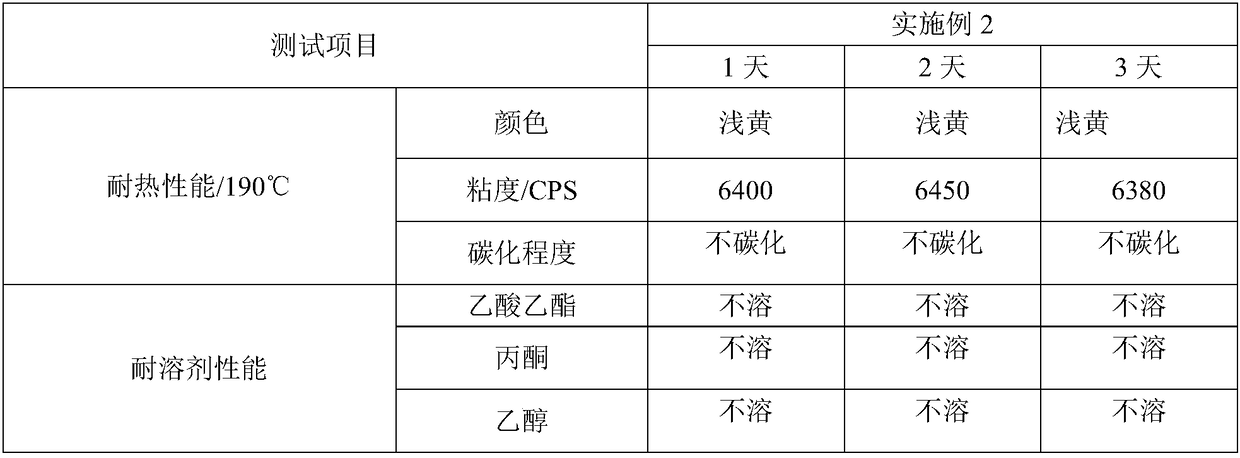

Embodiment 2

[0022] First, heat the reactor to 150°C, then add 20kg of SX-105 wax into the reactor for stirring, after the SX-105 wax is completely dissolved, add 54kg of 0#5100C5 hydrogenated petroleum resin (0#5100C5 hydrogenated petroleum resin is produced by the United States Kesen production) stir again, after 0#5100C5 hydrogenated petroleum resin dissolves, add 0.5kg antioxidant 1010, 0.5kg antioxidant first, 10kg amorphous polyolefin APAO8640, heat and stir and vacuumize, keep material temperature at 145 At about ℃, after all the components are dissolved, add 15kg of amorphous polyolefin APAO708, stir and vacuumize until all the components become transparent and uniform viscous liquid, then stop stirring and discharge while hot. That is, a hot melt adhesive is obtained. Take 100g of the prepared hot melt adhesive and place it in a 200ml beaker, place it in an oven at 190°C, and observe the color, viscosity, and degree of carbonization after 1, 2, and 3 days. The experimental data a...

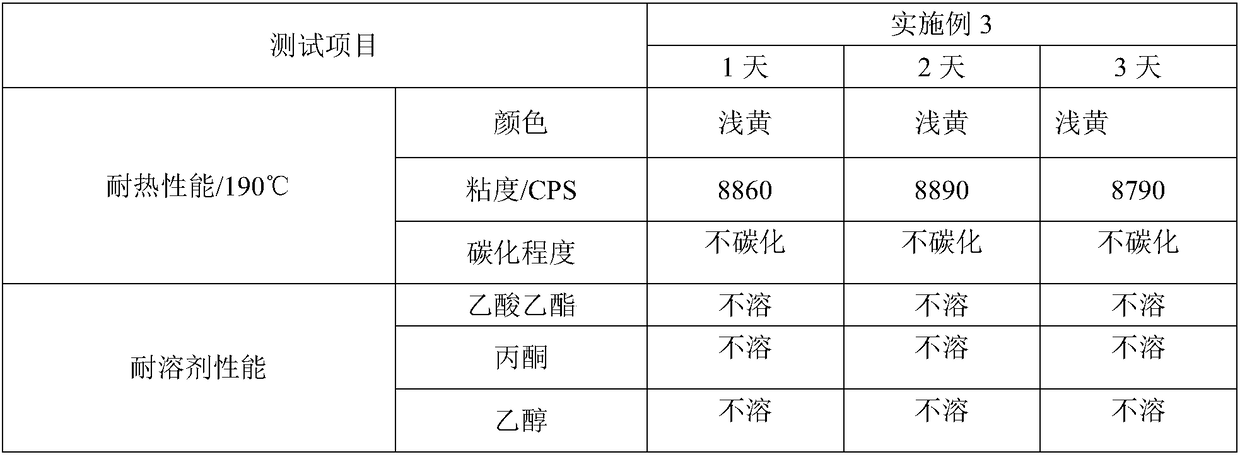

Embodiment 3

[0026] First heat the reactor to 145°C, then add 5kg of SX-105 wax into the reactor for stirring, after the SX-105 wax is completely dissolved, add 60kg of 5000C5 hydrogenated petroleum resin and stir again, after the 5000C5 hydrogenated petroleum resin is dissolved, add 0.9kg of antioxidant 1010, 0.1kg of antiaging agent A, 14kg of amorphous polyolefin APAO8640, heating and stirring and vacuuming, keeping the temperature of the material at about 145°C, after all the components are dissolved, add 20kg of amorphous polyolefin APAO708 , Stir and vacuumize until all components become transparent and uniform viscous liquid, then stop stirring and discharge while hot to obtain hot melt adhesive. Take 100g of the prepared hot melt adhesive and place it in a 200ml beaker, place it in an oven at 190°C, and observe the color, viscosity, and degree of carbonization after 1, 2, and 3 days. The experimental data are shown in Table 3 below:

[0027] table 3

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com