Manufacturing method of 1cr15ni36w3ti alloy forged and rolled bar for nuclear power

A manufacturing method and bar technology, which is applied in the field of rolling bar manufacturing and 1Cr15Ni36W3Ti alloy forging materials for nuclear power, can solve the problems of technical confidentiality, lack of production process and reference documents, and inability to obtain technical materials, etc., to achieve uniformity and consistency , Avoid coarse crystals and mixed crystals, good hereditary effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Rolled bar finished product specification: φ50mm

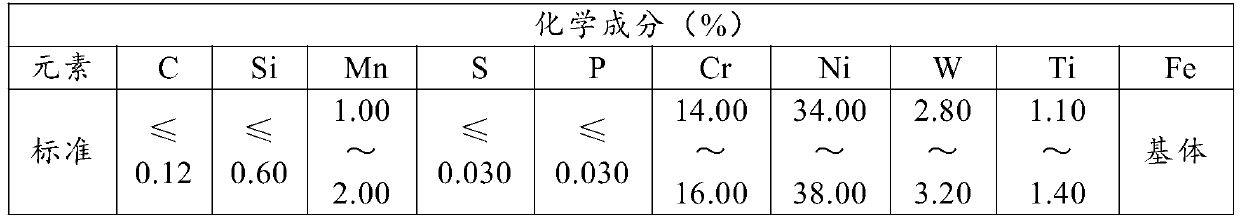

[0031] The alloy was smelted into ingots by non-vacuum induction furnace + electroslag remelting. The chemical composition is shown in Table 2.

[0032] Table 2

[0033]

[0034] The steel ingot is billeted to a 210mm octagonal billet by a 3150t fast forging machine. The heating temperature of the first fire for billet opening is 1060°C, and the heating temperature of the second fire is 1020°C. The temperature is 800°C; the heating temperature of 1800t precision forging billet opening is 1020°C, the total deformation is 30%, the surface is good, and the final forging temperature of precision forging is 850°C.

[0035] After the billet is polished, the surface is guaranteed to be free of defects, and it is used for rolling. The heating temperature of the first rolling fire is 1040°C, and the heating temperature of the second fire is 1020°C. During the heating process, the billet temperature is uniform, and the final...

Embodiment 2

[0045] Forged bar finished product specification: φ140mm

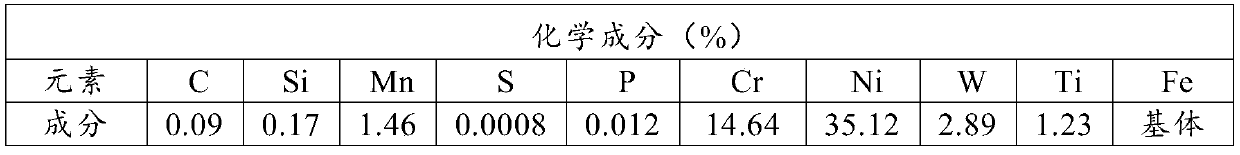

[0046] The alloy was smelted into ingots by non-vacuum induction furnace + electroslag remelting. The chemical composition is shown in Table 5.

[0047] table 5

[0048]

[0049] The steel ingot is billeted to a 210mm octagonal billet by a 3150t fast forging machine. The heating temperature of the first fire for billet opening is 1060°C, and the heating temperature of the second fire is 1020°C. The temperature is 820°C; the heating temperature of 1800t precision forging billet opening is 1030°C, the total deformation is 50%, the surface is good, and the final forging temperature of precision forging is 830°C.

[0050] After forging, the bar is subjected to finished product heat treatment, water-cooled at 1090°C for 3030 minutes, and air-cooled after aging at 700°C for 50 hours.

[0051] After heat treatment, the finished bar is finished, inspected, and packaged after passing the surface inspection.

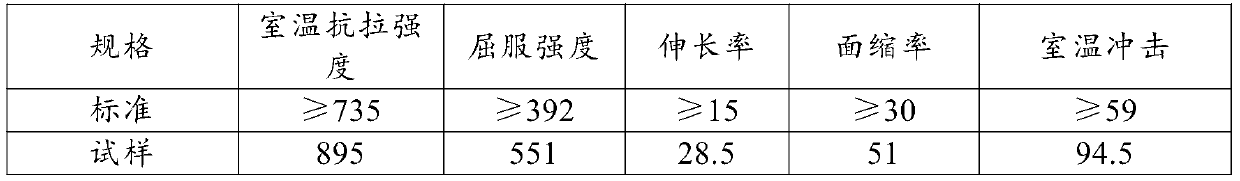

[0052] The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com