Oil well pipe for heavy oil thermal recovery well and its manufacturing method

A technology of heavy oil thermal recovery and manufacturing method, which is applied in the direction of manufacturing tools, heat treatment furnaces, heat treatment equipment, etc., can solve the problems of increased development difficulty, lack of corrosion resistance, increased or not reduced oil recovery, etc., to achieve excellent durability High temperature creep and strength attenuation resistance, CO2+O2 comprehensive corrosion resistance guarantee, mechanical properties are still stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

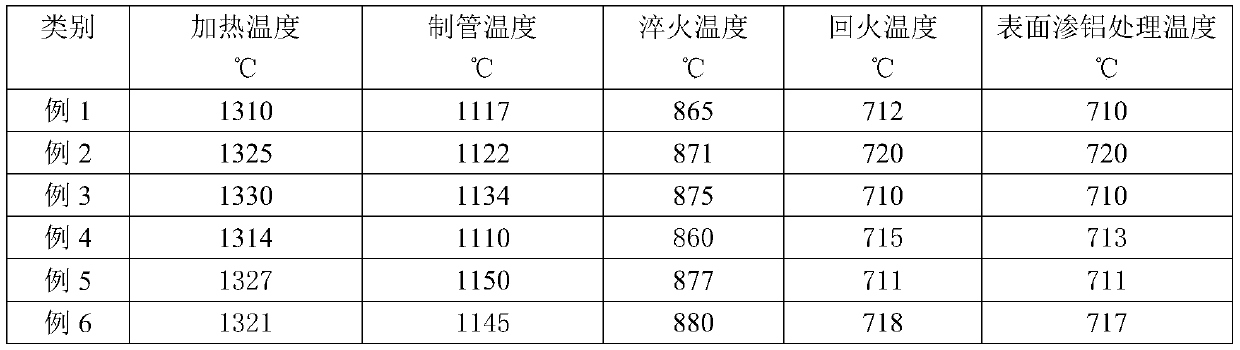

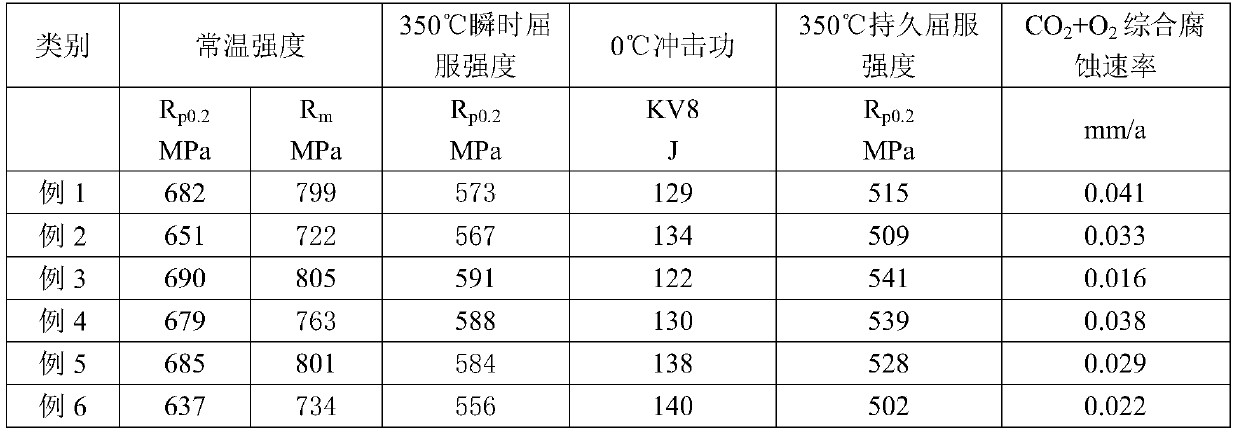

[0048] Table 1 shows the chemical composition of the steel in the example. The technological process is smelting and continuous casting—round billet manufacturing—seamless pipe—heat treatment. The heating temperature of the billet is controlled at 1300°C to 1350°C, and the temperature of the hot-rolled round billet is at 1150°C. ~1250°C control, the online heat treatment is preferred, and the surface aluminizing treatment is carried out by sealing and wrapping the steel pipe to be treated with an aluminizing agent and then heating. The specific process system of the pipe making and heat treatment in the embodiment is shown in Table 2, and Table 3 is the embodiment main mechanical properties.

[0049] The chemical composition (wt%) of the embodiment of table 1

[0050] category C Si mn P S Cr Nb Ti example 1 0.37 0.21 0.80 0.012 0.008 1.10 0.040 0.049 Example 2 0.40 0.15 0.75 0.017 0.010 1.38 0.052 0.060 Example 3 0.39 0.23 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com