Preparation method of rolled and annealed copper darkening ring, and rolled and annealed copper darkening ring

A technology of shading rings and diaphragms, which is applied in the field of photography, can solve problems such as the matte structure is easy to age and fall off, the shading ring is not easy to conduct electricity, and affects the light-shielding performance, etc., and achieves a stable matte black structure, easy blackening, and increased roughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

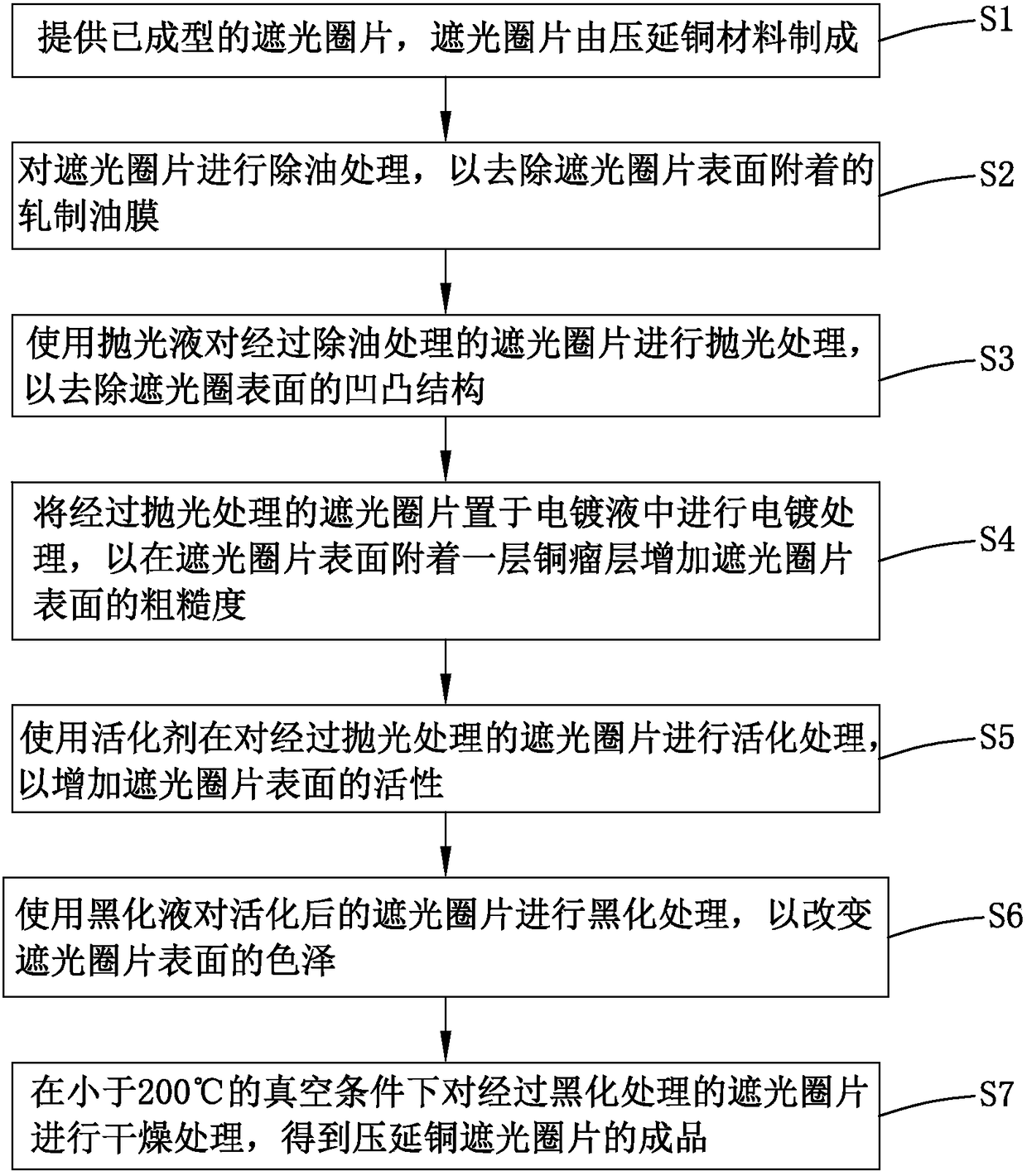

[0033] see figure 1 , the invention provides a method for preparing a rolled copper shading ring sheet, which comprises the steps of:

[0034] S1: Provide a formed shading ring, which is made of rolled copper.

[0035] Rolled copper is made by rolling copper ingots, then forging, anti-oxidation, roughening and other processes. The thickness of rolled copper is generally 5um ~ 135um. The molecules are tightly connected, with good flexibility, high strength, and bendability. , ductility, electroplating, good electrical conductivity, and excellent surface gloss; moreover, the rolled copper foil has low surface oxygen characteristics, and can be attached to various substrates, such as metals, insulating materials, etc., and has a wide range of temperature applications . The shading ring made of calendered copper material can avoid the shortcomings of PET material shading ring in the related art that are not resistant to aging, easy to deform, and not resistant to high temperatur...

Embodiment 1

[0059] The invention provides a method for preparing a rolled copper shading ring, which comprises the following steps:

[0060] (1) Provide a molded light-shielding ring piece made of rolled copper material.

[0061] (2) After washing with water, the light-shielding ring is ultrasonically cleaned for 10 minutes with acetone and 20 minutes with ethanol, so as to remove the rolling oil film attached to the surface of the light-shielding ring.

[0062] (3) After washing with water, the degreased light-shielding ring is polished with a copper polishing solution to remove the concave-convex structure on the surface of the light-shielding ring, and the polishing time is 5 minutes.

[0063] (4) After washing with water, place the polished light-shielding ring in the electroplating solution for electroplating, so as to attach a layer of copper bump layer on the surface of the light-shielding ring to increase the roughness of the light-shielding ring surface, The temperature of the e...

Embodiment 2

[0069] The invention provides a method for preparing a rolled copper shading ring, which comprises the following steps:

[0070] (1) Provide a molded light-shielding ring piece made of rolled copper material.

[0071] (2) After washing with water, ultrasonically clean the light-shielding ring for 20 minutes with acetone and 50 minutes with ethanol to remove the rolling oil film attached to the surface of the light-shielding ring.

[0072] (3) After washing with water, the degreased light-shielding ring is polished with a copper polishing solution to remove the concave-convex structure on the surface of the light-shielding ring, and the polishing time is 1 minute.

[0073] (4) After washing with water, place the polished light-shielding ring in the electroplating solution for electroplating, so as to attach a layer of copper bump layer on the surface of the light-shielding ring to increase the roughness of the light-shielding ring surface, The temperature of the electroplating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com