a blended yarn

A technology of blended yarn and vortex spinning, applied in the direction of yarn, textile and paper making, can solve the problems of difficult to grasp, easy sagging or breaking of the fiber net, small surface friction factor, etc., to achieve good air permeability, soft hand feeling, soft luster Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

[0019] The preferred embodiment is a blended yarn. The blended yarn is composed of 24%-27% cupro fiber, 46%-50% lyocell fiber and 24%-27% by mass. 27% cotton fiber composition. This blended yarn takes advantage of the strong frictional properties of cotton fibers to bind cupro fibers and lyocell fibers with poor cohesion together, so that through three drawing processes of first, second and last drawing, as well as vortex spinning The resulting blended yarn has stable spinnability.

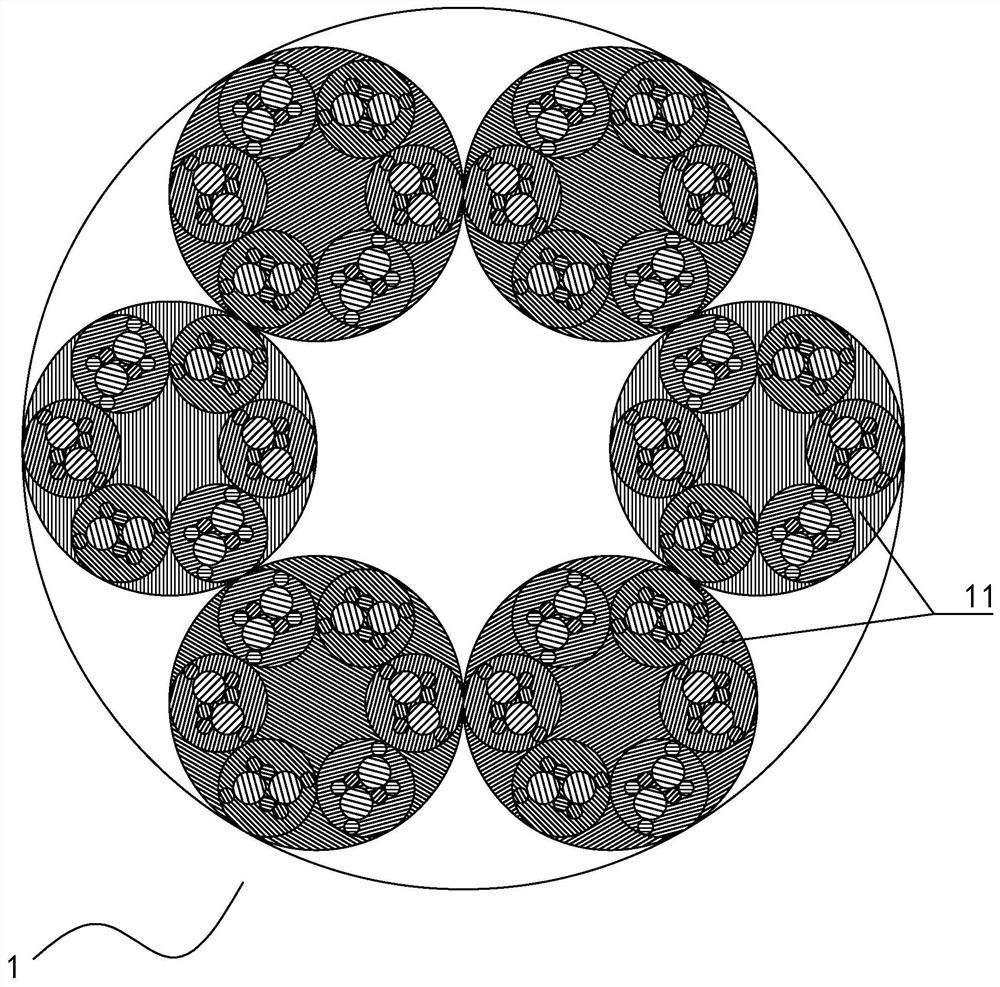

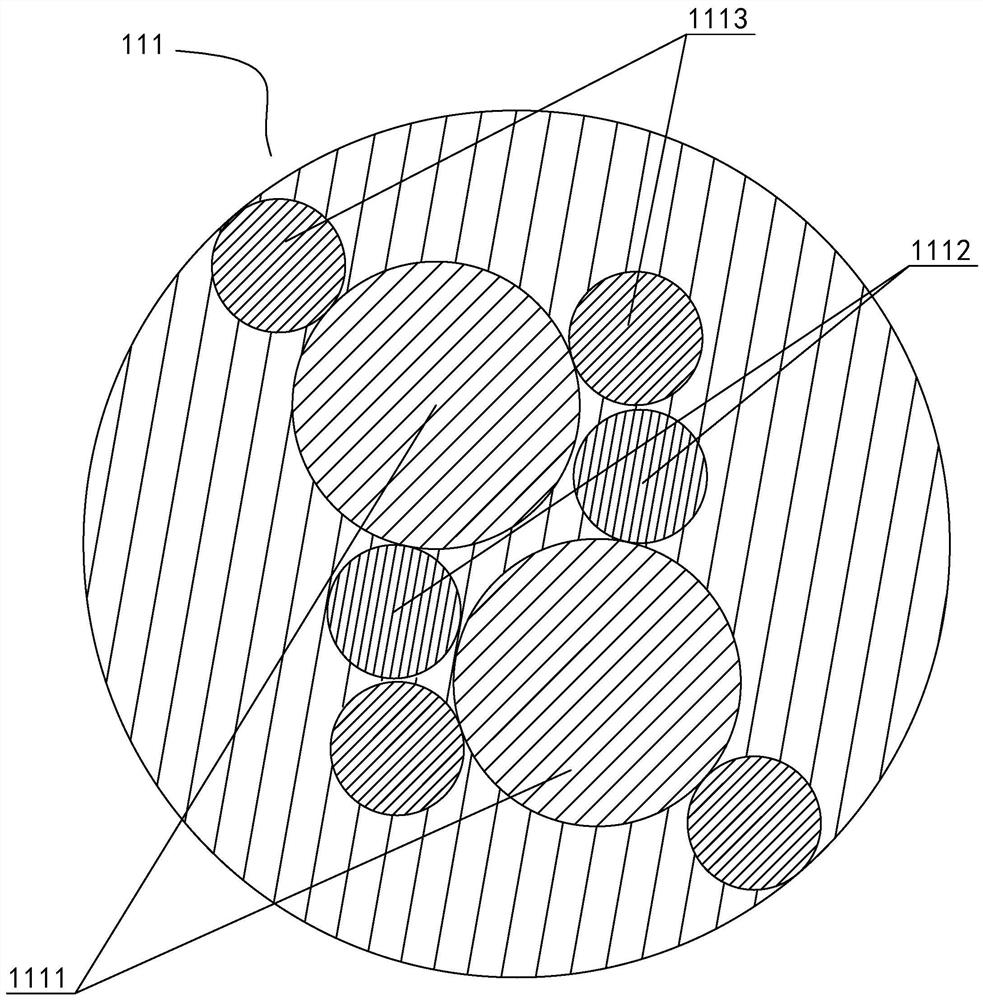

[0020] Preferably, the blended yarn is vortex spun by the final drawing frame 1, and the final drawing frame 1 is as figure 1 It is shown that it is formed by merging 6 second drawing frames 11, the second drawing frame 11 is formed by merging 6 first drawing frames 111, and the first drawing frame 111 is formed by two strands of cupro fiber 1112, four strands ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com