An industrial-grade method and device for producing 18o isotopes by cryogenic rectification

A low-temperature rectification and isotope technology, which is used in solidification, lighting and heating equipment, refrigeration and liquefaction, etc., can solve the problems of large raw material processing capacity, isotope rarity, difficulty in separation and extraction, and high yield of target isotopes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

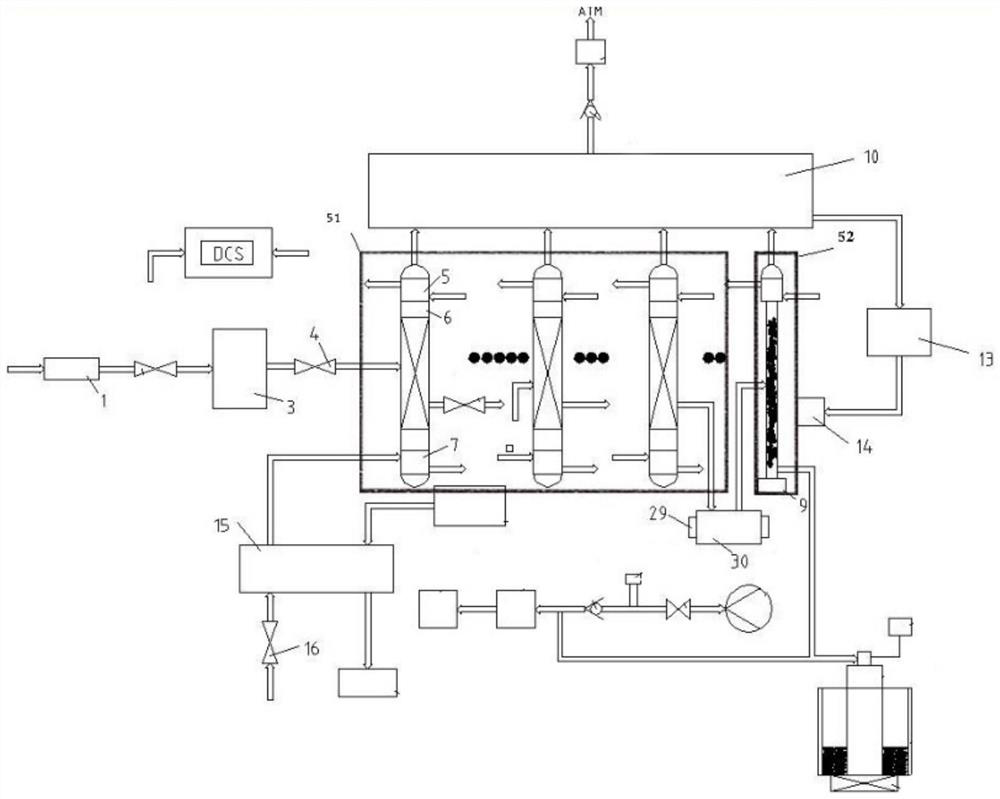

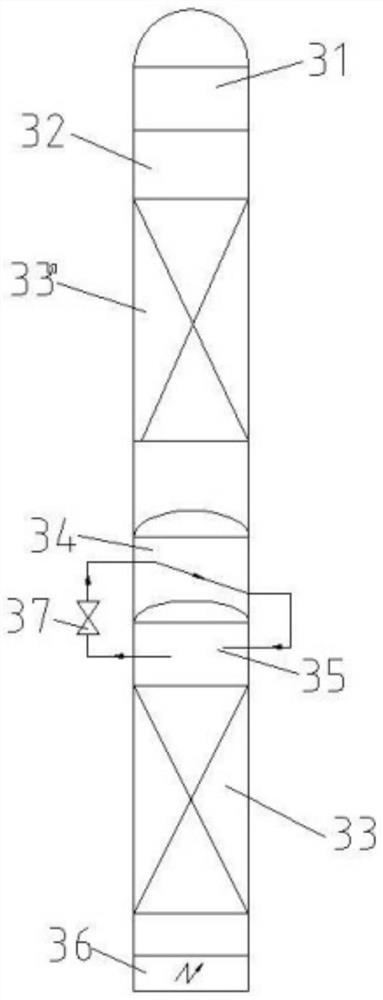

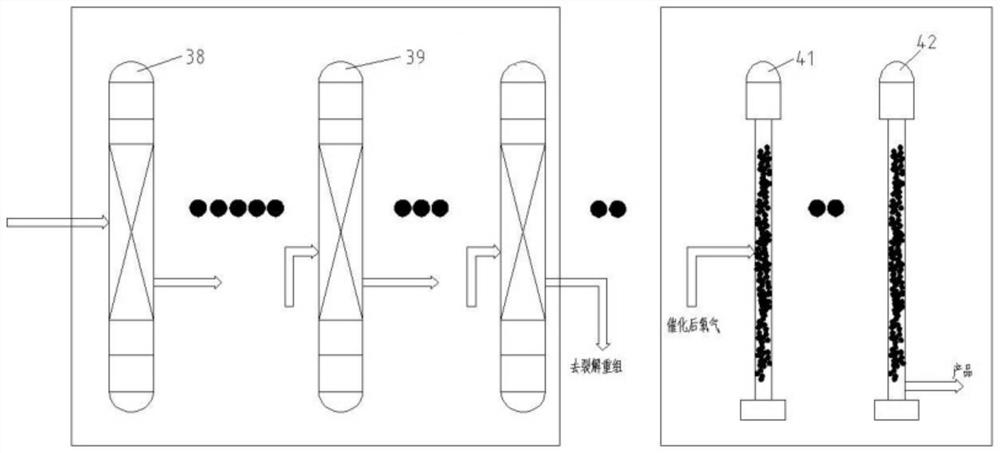

[0033] according to Figure 1 to Figure 10 An industrial-grade device for producing 18O isotopes by low-temperature rectification is shown, including an oxygen purification system, an oxygen 18 isotope rectification system and a filling system connected in sequence, and also includes the electrical control system and vacuum pumping system of the above three systems , the oxygen 18 isotope rectification system comprises successively series-connected structured packing towers 51 and step-by-step series-connected random packing towers 52, and more than one sub-tower is arranged in parallel between each level of structured packing towers 6; the last stage of structured packing A cracking and recombination mechanism is connected between the tower 51 and the random packing tower 52 of the first stage; the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com