A kind of preparation method of mgb2 single-core composite rod for extrusion

A composite rod, single-core technology, applied in the usage of superconductor elements, cable/conductor manufacturing, superconductor/high-conductor conductors, etc. effect of chemical preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1. Draw and process the commercial oxygen-free copper rod with the initial size of Φ15mm to a long oxygen-free copper rod of Φ8mm. After straightening, it is cut into several sections of oxygen-free copper short rods with lengths of 10mm, 15mm and 80mm by wire cutting equipment. 1. The two ends of each oxygen-free copper short rod 1 are ground and leveled respectively, then pickled to remove the surface oxide layer, cleaned and then removed the residual acid and dried;

[0027]In step 2, the oxygen-free copper short rod 1 dried in step 1 is placed in a vacuum heat treatment furnace for annealing heat treatment; the annealing heat treatment is vacuum annealing heat treatment, the temperature of vacuum annealing heat treatment is 500°C, and the holding time is 2h, Vacuum degree is less than 10 -3 Pa;

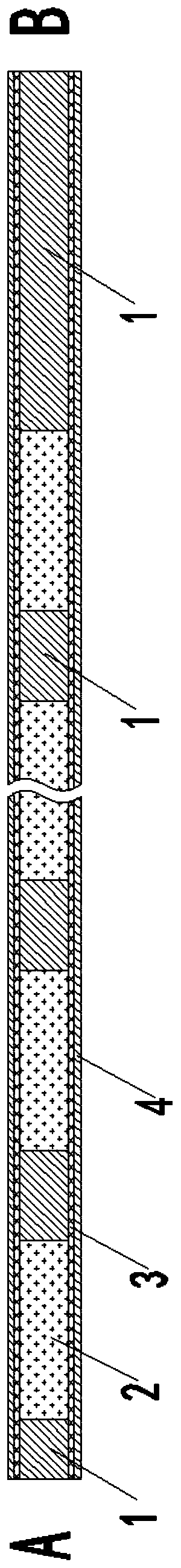

[0028] Step 3: First, plug the port A of the metal tube 3 with an oxygen-free copper short rod 1 with a size of Φ8×10mm after annealing and heat treatment in Step 2, ...

Embodiment 2

[0033] Step 1. Draw and process the commercial oxygen-free copper rod with the initial size of Φ16mm to a long oxygen-free copper rod of Φ9.5mm. After straightening, use wire cutting equipment to cut into several sections of oxygen-free copper with lengths of 10mm, 20mm and 90mm. Short rod 1, the two ends of each oxygen-free copper short rod 1 are ground and leveled respectively, and then pickled to remove the surface oxide layer, after cleaning, the residual acid is removed and dried;

[0034] Step 2: Place the oxygen-free copper short rod 1 dried in step 1 in a vacuum heat treatment furnace for annealing heat treatment; the annealing heat treatment is vacuum annealing heat treatment, the temperature of vacuum annealing heat treatment is 550°C, and the holding time is 1.5h , the vacuum degree is less than 10 -3 Pa;

[0035] Step 3: First, use the oxygen-free copper short rod 1 with a size of Φ9.5×10mm after annealing and heat treatment in step 2 to block the port A of the me...

Embodiment 3

[0039] Step 1. Draw and process the commercial oxygen-free copper rod with the initial size of Φ18mm to a long oxygen-free copper rod of Φ10mm. After straightening, use wire cutting equipment to cut into several sections of oxygen-free copper short rods with lengths of 10mm, 30mm and 100mm respectively. 1. The two ends of each oxygen-free copper short rod 1 are ground and leveled respectively, then pickled to remove the surface oxide layer, cleaned and then removed the residual acid and dried;

[0040] In step 2, the oxygen-free copper short rod 1 after drying in step 1 is placed in a vacuum heat treatment furnace for annealing heat treatment; the annealing heat treatment is vacuum annealing heat treatment, the temperature of vacuum annealing heat treatment is 600 ° C, and the holding time is 1 h, Vacuum degree is less than 10 -3 Pa;

[0041] Step 3, first use the oxygen-free copper short rod 1 with a size of Φ10×10mm after the annealing heat treatment in step 2 to block the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com