Quantum dot-coupled microstructure with prognosis preparation of quantum dot and preparation method thereof

A microstructure and quantum dot technology, applied in the field of quantum dots, can solve the problems of difficult quantum dot preparation, limited size control, high cost, etc., and achieve the effect of low cost, high repeatability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

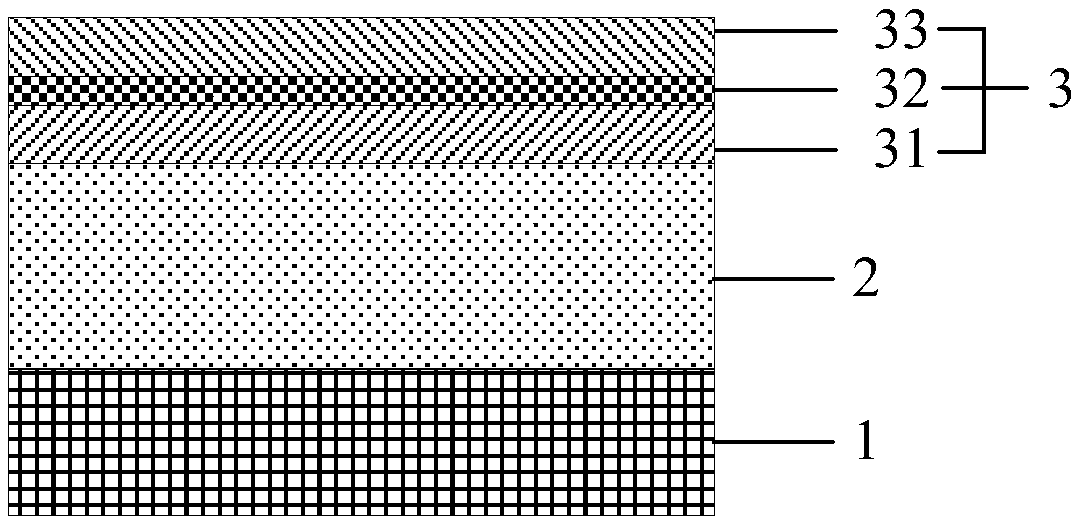

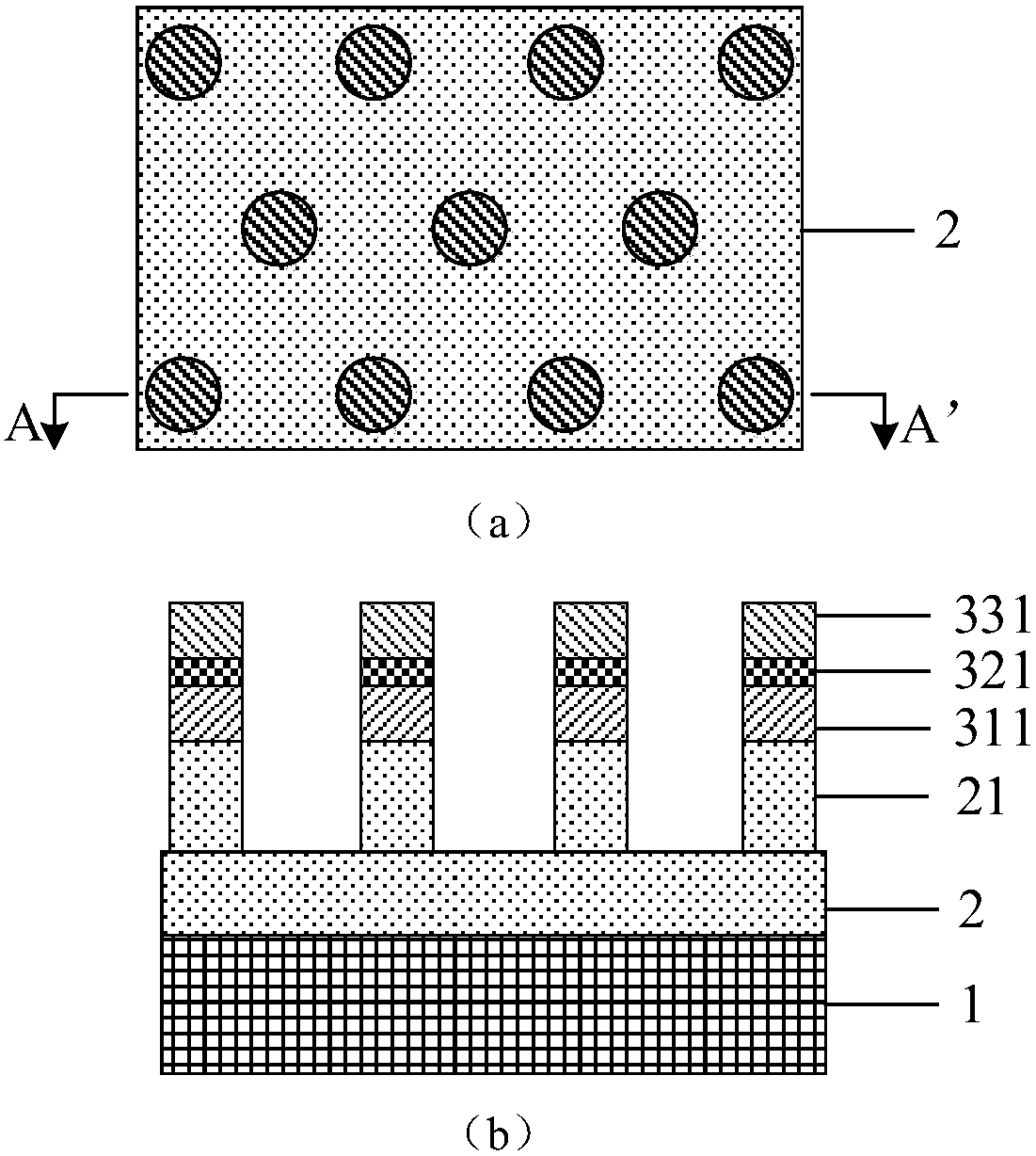

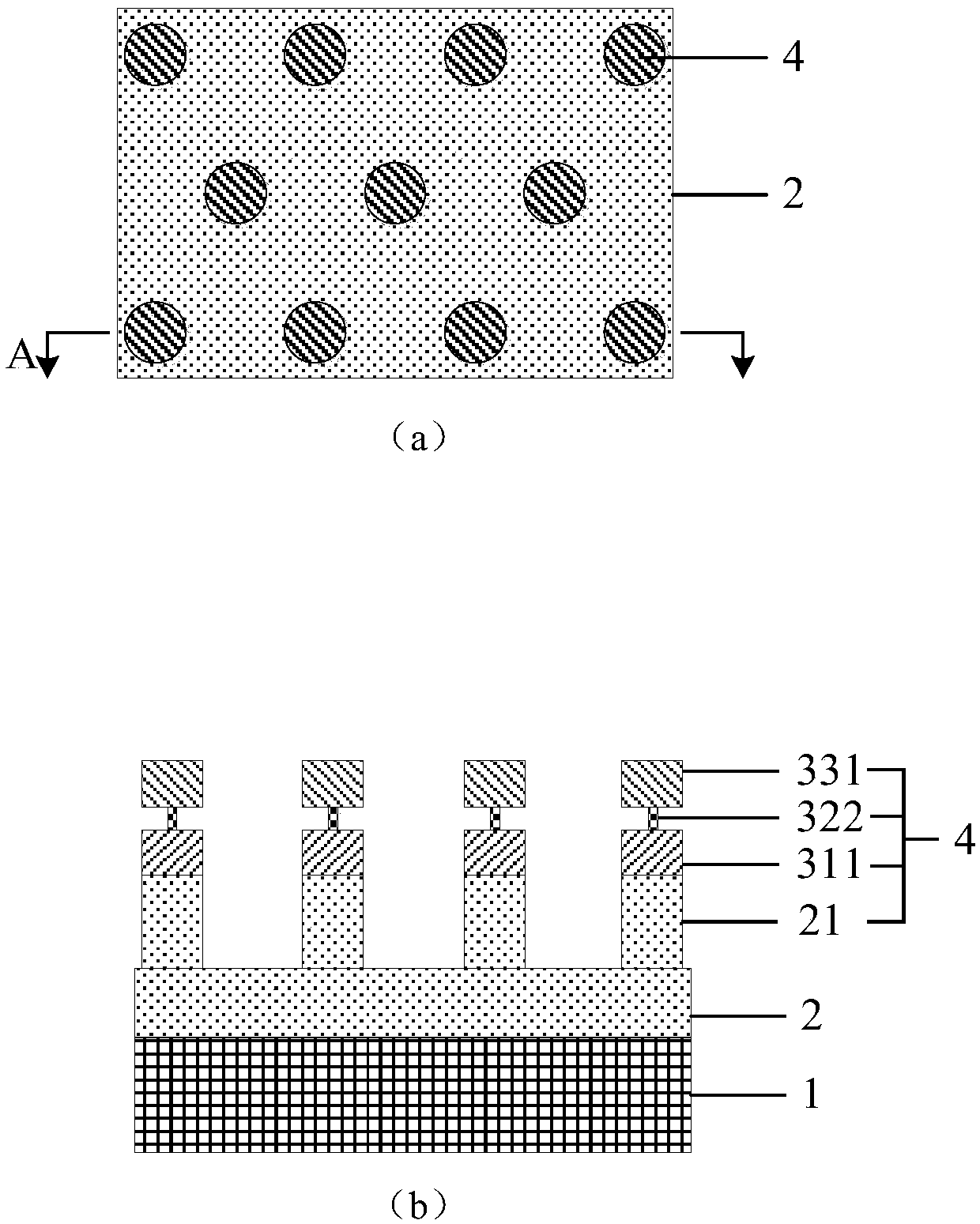

[0038] In this embodiment, the substrate adopts (0001) plane Al 2 o 3 , the epitaxial substrate is made of AlN, the quantum well structure is made of single quantum well, the bottom barrier is made of AlN, the quantum well is made of GaN, the thickness of the quantum well is 1nm (4 atomic layers), the top barrier is made of AlN, and the repair layer is made of AlN. The graphics of the microstructure adopt cylindrical array graphics.

[0039] In this embodiment, the quantum well structure is grown by molecular beam epitaxy MBE technology; the growth process is carried out in an ultra-high vacuum chamber, the high-purity (7N) metal source is produced by a K-Cell source furnace, and the nitrogen source is a radio frequency plasma nitrogen source . In MBE, the decomposition temperature of GaN is 800°C, and that of AlN is 1300°C (>800°C). Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com